RV* 4.6 Serpentine Trigger Wheel

Moderator: phpBB2 - Administrators

RV* 4.6 Serpentine Trigger Wheel

Does anyone know of a supplier that makes a 36-1 trigger wheel that will bolt straight up to a RV8 4.6 serpentine pulley. These have a curved inside face to the pulley and only two mounting holes.

Most suppliers seem to require machining of the pulley and drilling of extra holes etc.

Before I go down this route I am wanting to check to see if anyone makes a trigger wheel that will simply bolt straight up.

Thanks

Garry

Most suppliers seem to require machining of the pulley and drilling of extra holes etc.

Before I go down this route I am wanting to check to see if anyone makes a trigger wheel that will simply bolt straight up.

Thanks

Garry

-

stevieturbo

- Forum Contributor

- Posts: 4077

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Any pictures of your pulley ?

On all my V8's Ive used over the years I've done same simple thing with them all.

Have a small "flange" lathed onto the rear side of the pulley's inder diameter, and get a trigger wheel and open the hole out to this same size. Then just tack weld them together.

15 years like this and never a problem on a few engines.

On all my V8's Ive used over the years I've done same simple thing with them all.

Have a small "flange" lathed onto the rear side of the pulley's inder diameter, and get a trigger wheel and open the hole out to this same size. Then just tack weld them together.

15 years like this and never a problem on a few engines.

9.85 @ 144.75mph

202mph standing mile

http://www.youtube.com/watch?v=XgWRCDtiTQ0

202mph standing mile

http://www.youtube.com/watch?v=XgWRCDtiTQ0

Regards Tony C (COOPS)

MS2 V3.57 Ecu mapable efi and wasted spark ignition.

Procharger D1SC supercharger and Cossie RS500 Intercooler @ 14psi of Boost. 416 RWHP, (boost leak)

Forged 4.8 V8 kitted out with the dogs Cajones of parts.

Sponsored by: www.v8performanceparts.co.uk, www.interpart.biz, www.caprisport.com & www.baileyperformance.co.uk

MS2 V3.57 Ecu mapable efi and wasted spark ignition.

Procharger D1SC supercharger and Cossie RS500 Intercooler @ 14psi of Boost. 416 RWHP, (boost leak)

Forged 4.8 V8 kitted out with the dogs Cajones of parts.

Sponsored by: www.v8performanceparts.co.uk, www.interpart.biz, www.caprisport.com & www.baileyperformance.co.uk

-

stevieturbo

- Forum Contributor

- Posts: 4077

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Thanks for that. I take it that no one makes a trigger wheel that just bolts on and as I thought machining and other work will be required.

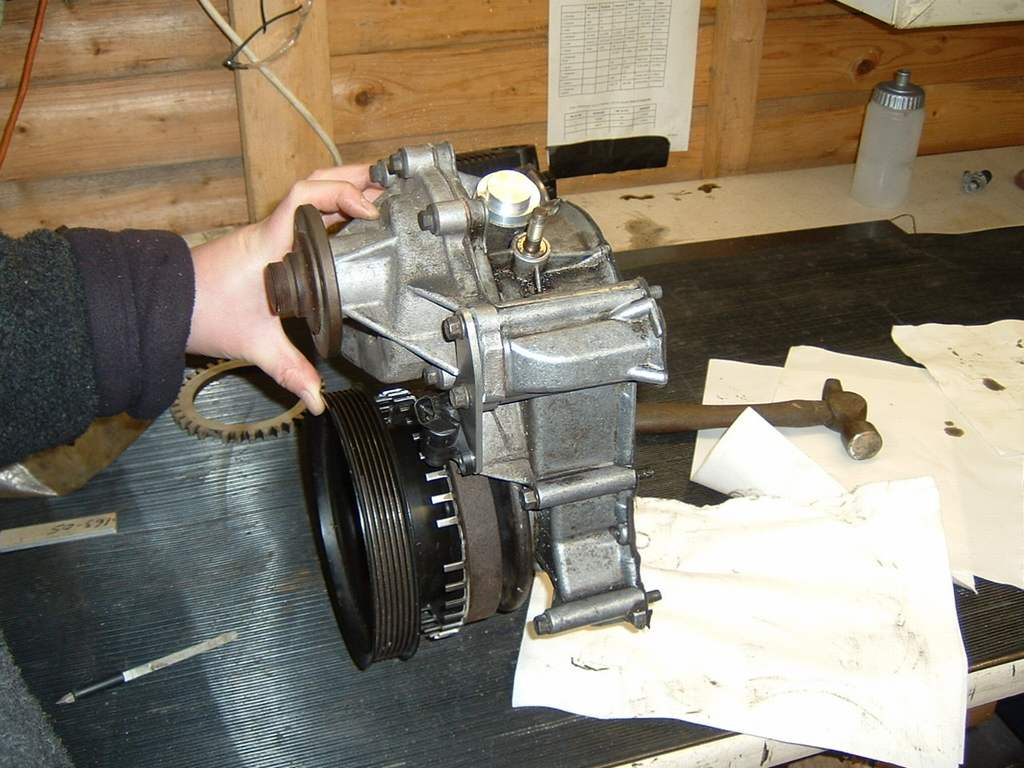

Here is the back of my pulley - it is 7" diameter.

So - from you have mentioned I am best to get a trigger wheel and machine the centre hole to the same as the flange on the pulley and then either weld or bolt the wheel down. (some trigger wheels have larger holes and you have to guess as getting the trigger wheel centred).

I will be getting a standard serpentine mount for the EDIS 8 sensor and does that provide enough adjustment to statically time the engine or should the trigger wheel also be able to move to increase the range of adjustment.

Also I was told by a supplier that the trigger wheel would need to be a little larger diameter that the pulley but I see in the pic above that it is much smaller diameter than the pulley.

Sorry as with all things Megaquirt there is mixed information that makes its installation harder than it needs to be.

Thanks for your help.

Garry

Here is the back of my pulley - it is 7" diameter.

So - from you have mentioned I am best to get a trigger wheel and machine the centre hole to the same as the flange on the pulley and then either weld or bolt the wheel down. (some trigger wheels have larger holes and you have to guess as getting the trigger wheel centred).

I will be getting a standard serpentine mount for the EDIS 8 sensor and does that provide enough adjustment to statically time the engine or should the trigger wheel also be able to move to increase the range of adjustment.

Also I was told by a supplier that the trigger wheel would need to be a little larger diameter that the pulley but I see in the pic above that it is much smaller diameter than the pulley.

Sorry as with all things Megaquirt there is mixed information that makes its installation harder than it needs to be.

Thanks for your help.

Garry

-

stevieturbo

- Forum Contributor

- Posts: 4077

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Doesnt look like there is a flat surface to bolt a wheel to ?

My method, wherever the diameter starts to increase, just lathe a small flange there to ensure the wheel will have a flat surface to rest against prior to welding.

Although depending on the diameter of the trigger wheel you choose, and diameter of sensor used....obviously you need room for both behind the pulley if the trigger wheel is smaller than the pulley itself.

So it may need to sit 1/2" back or so from the main pulley body.

My method, wherever the diameter starts to increase, just lathe a small flange there to ensure the wheel will have a flat surface to rest against prior to welding.

Although depending on the diameter of the trigger wheel you choose, and diameter of sensor used....obviously you need room for both behind the pulley if the trigger wheel is smaller than the pulley itself.

So it may need to sit 1/2" back or so from the main pulley body.

9.85 @ 144.75mph

202mph standing mile

http://www.youtube.com/watch?v=XgWRCDtiTQ0

202mph standing mile

http://www.youtube.com/watch?v=XgWRCDtiTQ0

If you are going to use EDIS, best to set the missing tooth accurately. It defaults to 10 BTDC with no SAW.

If there is a machined collar on the hub where the wheel will fit, I'd get a wheel which can be machined out to fit that. Don't really see why a decent two bolt fixing won't work - use spacing collars etc to keep it square. Slots on the wheel would be ideal so it can be set accurately.

If there is a machined collar on the hub where the wheel will fit, I'd get a wheel which can be machined out to fit that. Don't really see why a decent two bolt fixing won't work - use spacing collars etc to keep it square. Slots on the wheel would be ideal so it can be set accurately.

Dave

London SW

Rover SD1 VDP EFI

MegaSquirt2 V3

EDIS8

Tech Edge 2Y

London SW

Rover SD1 VDP EFI

MegaSquirt2 V3

EDIS8

Tech Edge 2Y

Thanks everyone - has eased my concerns about doing this. Nigel at MegaSquirt for V8s has a trigger wheel that fits this pulley (the back end has to be machined flat to the bolt holes) but he has some personal issues and his business is on hold.

I will do a mock up to see what outer diameter wheel is best and buy one that has a smaller inner hole so I can take it out to the exact size of the pulley flange.

Hi Chris - you solution is the obvious answer however this is going into an older vehicle using its flywheel which does not have the trigger. I could try to find an auto starter ring gear which has the trigger wheel rivetted to it and take it off and put it on my flywheel but it is easier to get get a trigger of the type discussed in this thread and install that.

Cheers

Garry

I will do a mock up to see what outer diameter wheel is best and buy one that has a smaller inner hole so I can take it out to the exact size of the pulley flange.

Hi Chris - you solution is the obvious answer however this is going into an older vehicle using its flywheel which does not have the trigger. I could try to find an auto starter ring gear which has the trigger wheel rivetted to it and take it off and put it on my flywheel but it is easier to get get a trigger of the type discussed in this thread and install that.

Cheers

Garry

Pretty sure that's the same pulley I fitted one to - I had to sandwich a thin ford 36-1 between the two outer pulleys. Also, as it was a griff 500, there were weights behind the inner mud slinger, so we didn't want to disturb them.

More pictures:

http://www.mez.co.uk/ms11-new.html

Looks like you can still buy the disc:

http://www.allcarpartsfast.co.uk/ford/f ... gn-timing/

More pictures:

http://www.mez.co.uk/ms11-new.html

Looks like you can still buy the disc:

http://www.allcarpartsfast.co.uk/ford/f ... gn-timing/

I went for machining the back of the 4.6 pulley so as to get a flat surface to bolt to so I could use the two existing holes to fix with. If you have access to a lathe, this ended up the neatest way.garrycol wrote:Thanks everyone - has eased my concerns about doing this. Nigel at MegaSquirt for V8s has a trigger wheel that fits this pulley (the back end has to be machined flat to the bolt holes) but he has some personal issues and his business is on hold.

I will do a mock up to see what outer diameter wheel is best and buy one that has a smaller inner hole so I can take it out to the exact size of the pulley flange.

Hi Chris - you solution is the obvious answer however this is going into an older vehicle using its flywheel which does not have the trigger. I could try to find an auto starter ring gear which has the trigger wheel rivetted to it and take it off and put it on my flywheel but it is easier to get get a trigger of the type discussed in this thread and install that.

Cheers

Garry

The 4.0/4.6 type pulley is not at all like the earlier serp pulleys and doesn't have the six fixing holes. It's about 20mm thinner o/a and as there is no dizzy the cover is also 20mm thinner and the multi belt is 20mm nearer the block. So space is tight behind the pulley.

Cheers Denis

Hi Denis - thanks for that.

What diameter trigger wheel did you put on. It has been suggested I go to 8.25" but I think that will be too big and will require a one off mount to get the sensor in the right spot.

Steviturbos pic has a smaller dia wheel that may fit in better.

Now looking for suggestions on specific sizes etc from people who have the same pulley as I have.

I am now lookinf turning the back of the pulley down so it is flat to a few mm past the two bolt holes.

Cheers

Garry

What diameter trigger wheel did you put on. It has been suggested I go to 8.25" but I think that will be too big and will require a one off mount to get the sensor in the right spot.

Steviturbos pic has a smaller dia wheel that may fit in better.

Now looking for suggestions on specific sizes etc from people who have the same pulley as I have.

I am now lookinf turning the back of the pulley down so it is flat to a few mm past the two bolt holes.

Cheers

Garry

-

stevieturbo

- Forum Contributor

- Posts: 4077

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Thanks - but I don't have any hardware so I don't know what I want or is convenient. Living in Aust, it is not as if I can duck down to the local shop and change what I get if it is wrong - hence I need to get what works in the same situation as my pulley.stevieturbo wrote:Use whatever diameter is convenient for you to mount a sensor.

Chris - Thanks for the information

Cheers

Garry

Last edited by garrycol on Wed Feb 17, 2016 2:02 am, edited 2 times in total.