Lifting the floor (slightly)

Moderator: phpBB2 - Administrators

Lifting the floor (slightly)

Hi guys, after a little further tweaking of my bowls etc I thought i would post my progress on reworking my current heads for my top end rebuild.

http://i1064.photobucket.com/albums/u36 ... age-15.jpg

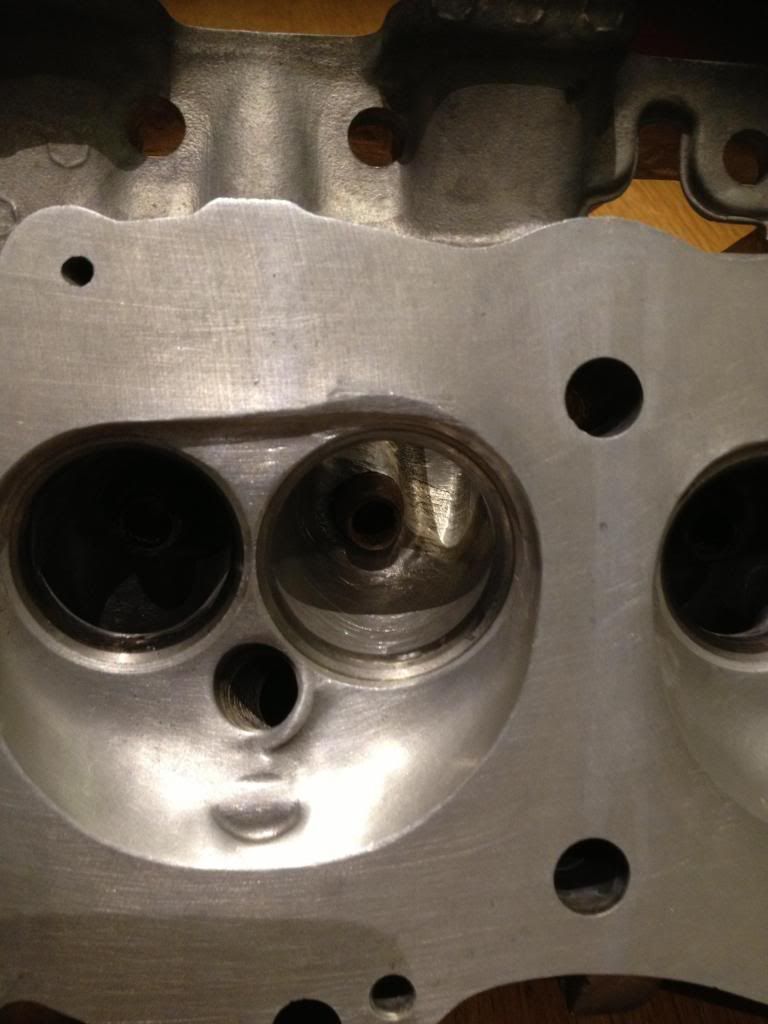

Port roof lifted and exhausts cleaned up (already maximum volume IMHO). Pics of roof lift featrured earlier. Good key put on the inlet floor with a few blobs of anchoring weld.

http://i1064.photobucket.com/albums/u36 ... age-16.jpg

Tape was aimed across the floor of each port - aiming for the same volume as the initially reworked port but higher. The resin fill is equivalent to the lift of the roof.

http://i1064.photobucket.com/albums/u36 ... age-17.jpg

So I want to be careful to maintain the taper inwards closing the CSA towards the valve. Next is to sand excess and blend into the short side turn.

http://i1064.photobucket.com/albums/u36 ... age-15.jpg

Port roof lifted and exhausts cleaned up (already maximum volume IMHO). Pics of roof lift featrured earlier. Good key put on the inlet floor with a few blobs of anchoring weld.

http://i1064.photobucket.com/albums/u36 ... age-16.jpg

Tape was aimed across the floor of each port - aiming for the same volume as the initially reworked port but higher. The resin fill is equivalent to the lift of the roof.

http://i1064.photobucket.com/albums/u36 ... age-17.jpg

So I want to be careful to maintain the taper inwards closing the CSA towards the valve. Next is to sand excess and blend into the short side turn.

Spent so much on trial and error!

Re: Lifting the floor (slightly)

DaviesDJ wrote:Hi guys, after a little further tweaking of my bowls etc I thought i would post my progress on reworking my current heads for my top end rebuild.

http://i1064.photobucket.com/albums/u36 ... age-15.jpg

Port roof lifted and exhausts cleaned up (already maximum volume IMHO). Pics of roof lift featrured earlier. Good key put on the inlet floor with a few blobs of anchoring weld.

http://i1064.photobucket.com/albums/u36 ... age-16.jpg

Tape was aimed across the floor of each port - aiming for the same volume as the initially reworked port but higher. The resin fill is equivalent to the lift of the roof.

http://i1064.photobucket.com/albums/u36 ... age-17.jpg

So I want to be careful to maintain the taper inwards closing the CSA towards the valve. Next is to sand excess and blend into the short side turn.

All looks quite complicated to me DJ. Whats the idea of the blobs of weld in the runners ?

Pel

Perry Stephenson

MGB GT + Rover V8

9.62 @ 137.37mph

Now looking for 8 seconds with a SBC engine

http://www.youtube.com/watch?v=nVscbPHgue0&list=UUqIlXfSAoiZ--GyG4tfRrjw

https://www.youtube.com/watch?v=eg3avnsNKrc&index=2&list=FLqIlXfSAoiZ--GyG4tfRrjw

MGB GT + Rover V8

9.62 @ 137.37mph

Now looking for 8 seconds with a SBC engine

http://www.youtube.com/watch?v=nVscbPHgue0&list=UUqIlXfSAoiZ--GyG4tfRrjw

https://www.youtube.com/watch?v=eg3avnsNKrc&index=2&list=FLqIlXfSAoiZ--GyG4tfRrjw

HI Pel, the blobs of weld are intneded to provide a really good key/grip for the epoxy. i am actuqally quite pleased with how it 'seems' to have turned out. This evening I will ceramic coat the bowls and then polish them, then finally lap in the valves. It will probarbly either make no difference or cause catastrophic problems knowing my luck. But I can t help myself Pel, I am still to green to know when to just keep it simple  Obviously my manifold runners will be matched and this will be easier.

Obviously my manifold runners will be matched and this will be easier.

Spent so much on trial and error!

That makes sense

If you are lapping the valves in then get one of those EEZI lap things from Halfords to go in the battery drill. I got mine a year ago and have been kicking myself ever since over how much time I've wasted lapping valves in over the last 10 years. Once you get the hang of how to use it your life will be a lot easier

Pel

If you are lapping the valves in then get one of those EEZI lap things from Halfords to go in the battery drill. I got mine a year ago and have been kicking myself ever since over how much time I've wasted lapping valves in over the last 10 years. Once you get the hang of how to use it your life will be a lot easier

Pel

Perry Stephenson

MGB GT + Rover V8

9.62 @ 137.37mph

Now looking for 8 seconds with a SBC engine

http://www.youtube.com/watch?v=nVscbPHgue0&list=UUqIlXfSAoiZ--GyG4tfRrjw

https://www.youtube.com/watch?v=eg3avnsNKrc&index=2&list=FLqIlXfSAoiZ--GyG4tfRrjw

MGB GT + Rover V8

9.62 @ 137.37mph

Now looking for 8 seconds with a SBC engine

http://www.youtube.com/watch?v=nVscbPHgue0&list=UUqIlXfSAoiZ--GyG4tfRrjw

https://www.youtube.com/watch?v=eg3avnsNKrc&index=2&list=FLqIlXfSAoiZ--GyG4tfRrjw

I just use a cordless drill on the valve stem.mgbv8 wrote:That makes sense

If you are lapping the valves in then get one of those EEZI lap things from Halfords to go in the battery drill. I got mine a year ago and have been kicking myself ever since over how much time I've wasted lapping valves in over the last 10 years. Once you get the hang of how to use it your life will be a lot easier

Pel

Chris.

--

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

ChrisJC wrote:I just use a cordless drill on the valve stem.mgbv8 wrote:That makes sense

If you are lapping the valves in then get one of those EEZI lap things from Halfords to go in the battery drill. I got mine a year ago and have been kicking myself ever since over how much time I've wasted lapping valves in over the last 10 years. Once you get the hang of how to use it your life will be a lot easier

Pel

Chris.

Thats what Ive done for years Chris, and it works ok as long as you dont get to physical with the chuck. But this thing is great as it oscillates and you control how slow or quick the valve rotates in the seat. Next time you are doing some valves I'll lend you mine to play with mate. I'll be surprised if you are not impressed with it

Happy New year!

Pel

Perry Stephenson

MGB GT + Rover V8

9.62 @ 137.37mph

Now looking for 8 seconds with a SBC engine

http://www.youtube.com/watch?v=nVscbPHgue0&list=UUqIlXfSAoiZ--GyG4tfRrjw

https://www.youtube.com/watch?v=eg3avnsNKrc&index=2&list=FLqIlXfSAoiZ--GyG4tfRrjw

MGB GT + Rover V8

9.62 @ 137.37mph

Now looking for 8 seconds with a SBC engine

http://www.youtube.com/watch?v=nVscbPHgue0&list=UUqIlXfSAoiZ--GyG4tfRrjw

https://www.youtube.com/watch?v=eg3avnsNKrc&index=2&list=FLqIlXfSAoiZ--GyG4tfRrjw

The epoxy is on the inlet port floor, and shoul hold- it has weld in the floor to make a really good key! The roller rockers came in this box. I will post a pic of the rockers themselves later!

I am going to buy some new rocker shafts to mount them on. Do you guys think it is worth going for the cheap pattern ones?? Or OEM, oil ways and surface are my concern. Have decided on the real steel typhoon cam- the combo of lift and LCA I think are good, although the crower has more lift I measured my valves in situ and from the bottom of the retainer/collet is 0.49 inches above the top of the neoprene seal, with the 885 tvr can I was ok but I am not sure how much lift this has (anybody know???) but things were ok with this. Is it advisable that lift pushes down on the neoprene seal at all? As there is a bit more lift if you factor that in but I am not sure.

I would love to flow these heads on a proper bench to spec the cam but darkspeed (who offered kindly) cannot help for a good few weeks and I want this ready in 2-3 weeks. With the Eddie performer and 5.0 tvr bottom end (not ideal I admit!) I am hoping for north of 300 HP without gas.

I am going to buy some new rocker shafts to mount them on. Do you guys think it is worth going for the cheap pattern ones?? Or OEM, oil ways and surface are my concern. Have decided on the real steel typhoon cam- the combo of lift and LCA I think are good, although the crower has more lift I measured my valves in situ and from the bottom of the retainer/collet is 0.49 inches above the top of the neoprene seal, with the 885 tvr can I was ok but I am not sure how much lift this has (anybody know???) but things were ok with this. Is it advisable that lift pushes down on the neoprene seal at all? As there is a bit more lift if you factor that in but I am not sure.

I would love to flow these heads on a proper bench to spec the cam but darkspeed (who offered kindly) cannot help for a good few weeks and I want this ready in 2-3 weeks. With the Eddie performer and 5.0 tvr bottom end (not ideal I admit!) I am hoping for north of 300 HP without gas.

Spent so much on trial and error!