Another cylinder head questioin

Moderator: phpBB2 - Administrators

Another cylinder head questioin

Hello all

I have a 3.5 RV8 from a P5B, circa 1970 ish (rope seals and all). It's in bits right now and I am slowly reassembling it. I was given some cylinder heads this week with the intention of using the rocker shaft assemblies on my original heads, since the shafts show no wear at all and my original ones were shot. Having read several other threads on here I am now considering ditching my heads in favour of the new ones, given that a) they appear to be better in every way and b) will have hardened valve seats for that additional peace of mind running on unleaded.

They have casting number HRC 2210 which according to the sticky on this forum makes them early 90s EFi heads. The page suggests they have been machined by Rover to use composite head gaskets. Does this mean they will bolt straight on to my P5B block using a composite gasket with no modifications required? Are all HRC 2210 heads like this or are there differences? Am I likely to experience any issues doing this, or should I just stick to my original heads and use a tin gasket?

A point of note, the engine is to be used in a V8 trike so I am not desperate to squeeze maximum power from it. I like the idea of using a composite gasket but have spent so long cleaning and fettling and measuring things I don't want to take on any more trouble if possible.

Thanks in advance,

Simon

I have a 3.5 RV8 from a P5B, circa 1970 ish (rope seals and all). It's in bits right now and I am slowly reassembling it. I was given some cylinder heads this week with the intention of using the rocker shaft assemblies on my original heads, since the shafts show no wear at all and my original ones were shot. Having read several other threads on here I am now considering ditching my heads in favour of the new ones, given that a) they appear to be better in every way and b) will have hardened valve seats for that additional peace of mind running on unleaded.

They have casting number HRC 2210 which according to the sticky on this forum makes them early 90s EFi heads. The page suggests they have been machined by Rover to use composite head gaskets. Does this mean they will bolt straight on to my P5B block using a composite gasket with no modifications required? Are all HRC 2210 heads like this or are there differences? Am I likely to experience any issues doing this, or should I just stick to my original heads and use a tin gasket?

A point of note, the engine is to be used in a V8 trike so I am not desperate to squeeze maximum power from it. I like the idea of using a composite gasket but have spent so long cleaning and fettling and measuring things I don't want to take on any more trouble if possible.

Thanks in advance,

Simon

Hi

Go with the newer heads, they are heaps better, you can as you say use them with composite gaskets without further skimming. I would still shim the rocker pillars to set the preload correctly on the tappets, but nothing else to do for them to work.

If you can find the time a quick clean up of the castings would be worthwhile, just to remove the casting marks and any sudden transitions from machining to casting, it will just make pick-up crisper and it will be easier to set up the engine but just a clean up.

Best regards

Mike

Go with the newer heads, they are heaps better, you can as you say use them with composite gaskets without further skimming. I would still shim the rocker pillars to set the preload correctly on the tappets, but nothing else to do for them to work.

If you can find the time a quick clean up of the castings would be worthwhile, just to remove the casting marks and any sudden transitions from machining to casting, it will just make pick-up crisper and it will be easier to set up the engine but just a clean up.

Best regards

Mike

poppet valves rule!

Hi Mike

Thanks for the reply. Just wanted to confirm my understanding was correct, there aren't tin gasket and composite gasket varieties of the HRC 2210 and I can go ahead and order some composite ones without having to get the heads machined.

Next question, looking at the Real Steel website there seems to only be one type of composite gasket for the 3.5 engine, but flicking through ebay there seem to be early and late types on offer, some being 10 bolt and some 14. My new heads are 14 holes but I have read on here it's advisable to leave the 4 bolts at the exhaust manifold side out and only use 10 bolts. Is this correct? And can I therefore get a later 10 bolt gasket from any engine size RV8 for this application?

Thanks for the reply. Just wanted to confirm my understanding was correct, there aren't tin gasket and composite gasket varieties of the HRC 2210 and I can go ahead and order some composite ones without having to get the heads machined.

Next question, looking at the Real Steel website there seems to only be one type of composite gasket for the 3.5 engine, but flicking through ebay there seem to be early and late types on offer, some being 10 bolt and some 14. My new heads are 14 holes but I have read on here it's advisable to leave the 4 bolts at the exhaust manifold side out and only use 10 bolts. Is this correct? And can I therefore get a later 10 bolt gasket from any engine size RV8 for this application?

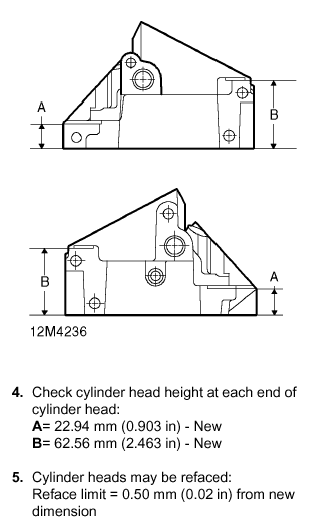

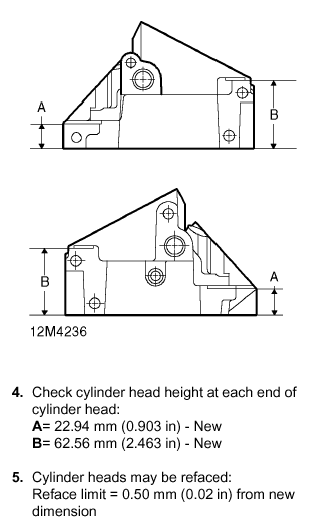

The composite type heads can be checked by taking these measurements:

You might want to check that the ancillary fixing locations are OK for your application. I don't think they ever moved any, just added more over the years.

Go for 10bolts, all composite engines only used 10 bolts. Just ignore the extra holes. Up to you whether you prefer the earlier torque-them-up type bolts, or the single use stretch bolts.

There are two bore sizes, 3.5" and 3.7". The 3.5" bore what used on the 3.5l engines, 3.7" bore on 3.9, 4.0, 4.2, 4.6. Therefore you should make sure you get a composite gasket with the right bore size.

Chris.

You might want to check that the ancillary fixing locations are OK for your application. I don't think they ever moved any, just added more over the years.

Go for 10bolts, all composite engines only used 10 bolts. Just ignore the extra holes. Up to you whether you prefer the earlier torque-them-up type bolts, or the single use stretch bolts.

There are two bore sizes, 3.5" and 3.7". The 3.5" bore what used on the 3.5l engines, 3.7" bore on 3.9, 4.0, 4.2, 4.6. Therefore you should make sure you get a composite gasket with the right bore size.

Chris.

--

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8