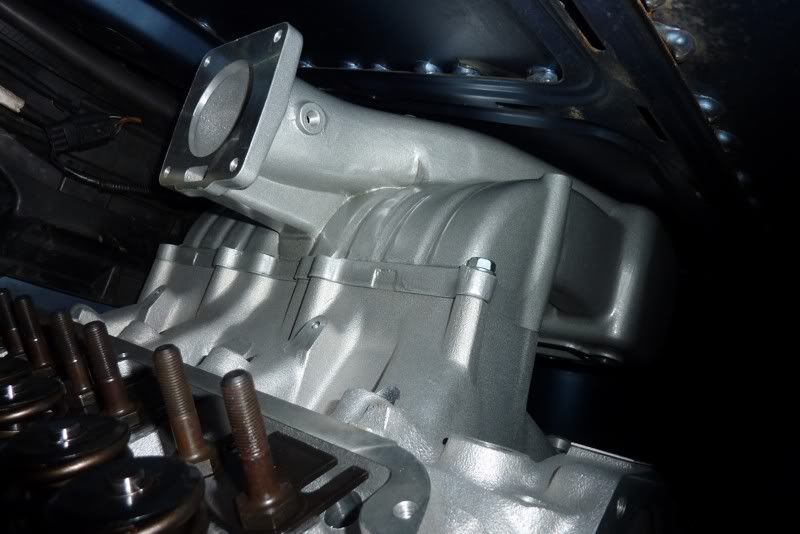

Need to drop the whole lot out the bottom again to bash the transmission tunnel some more with a hammer.

Mark

Moderator: phpBB2 - Administrators

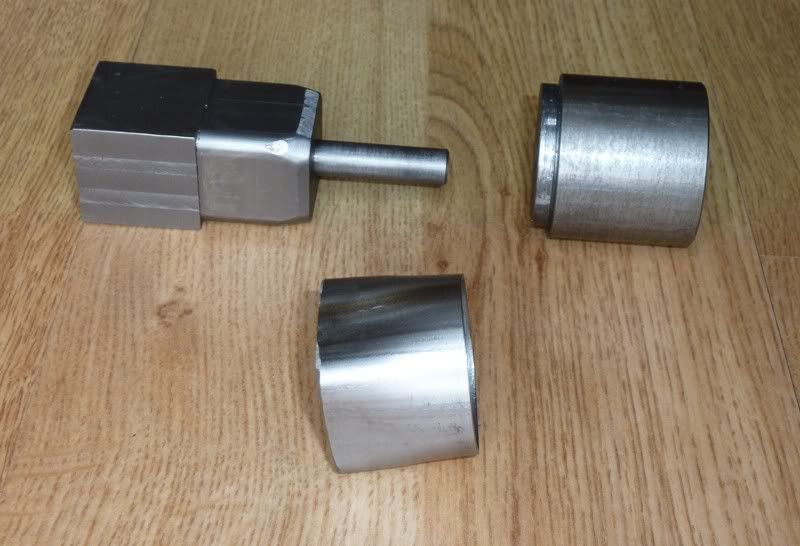

The smaller diameter on the round bit fits inside the pipe to keep it round, both the square part and the round part have a 12mm reamed hole and the 12mm sliver steel fits both parts and keeps it all square.demo2 wrote:That square to round tool does a neat job, how does it compress together ?

They look like a good ideaEliot wrote:I used these serrated washers under my cap screws:

http://www.calebcomp.co.uk/products/hea ... shers.html

I was under the impression that stainless needed purging full stop ?stevieturbo wrote:If you are TIG welding, make sure you backpurge so the weld doesnt intrude into the pipe.

If it was me though, I'd just MIG. It's neat, quick and easy, and you dont need to worry about backpurging.