bigaldart wrote:Look for a Gates belt supplier in the uk. A lot of agricultural equipment uses the belts so there are suppliers scattered over the country. We use 8mm Taperlock pulleys as opposed to the typical american style aluminium ones. No problems at all with them, they locate with a key and use allen screws to secure. Swap one screw to another hole and it acts as a puller to break the taper. Very flexible and masses of sizes available.

Be careful with the wade though as they don't live long at higher rpm's On a road car aim for 5,500 maximum blower speed.

Alan

Hi all

Right a few more details.

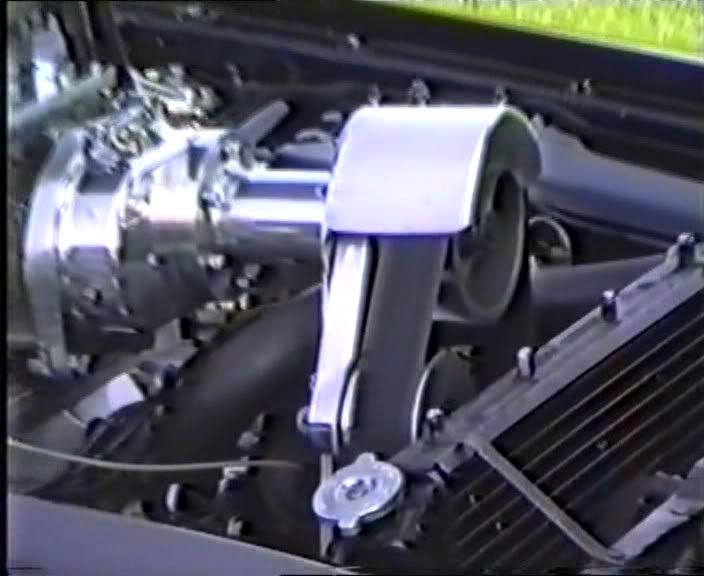

The toth pitch is 8mm all 3 of the pullys i have are the same size. i was going to use one for the crank and the other to make up the tensonor

The engine is curentley 8.1-1 comp and is from a landrover 101 i now have 2 nice heads for a 3.9 so have the bigger valves and intend to fit to the 101 block

Not sure what compresion ratio i will end up with? also do you think i should be changing the crank pully or will a 1-1 drive boost to a sensable value 6-8 psi?

I alos have a nice blower cam and folowers rpi head studs and duplex chain set all ready to fit

Thanks again for all the good info

Like i say i am a bit new to blowing engines so any help is very welcome

Cheers

Derek