With my car all but done now I thought that it would be a good idea to try and keep the front end from getting light at speed.

The car was on the road in a former guise and even with that motor things got a little hairy at 80 plus.

So I thought about making a splitter to help keep it down and fully planted.

Some of you have already helped me with advice on this so am taking the plunge and going for it.

Here is the first installment...

1 Made sure that the car had equal tyre pressures and was level to begin with.

2 Placed my template under the car and levelled that off too.

3 Using a thickish marker pen I then scribed around the leading edge to get the shape required

4 I then checked that the gaps were equal from the bottom outer edges of the spoiler to the template and found that the n/s was lower than the other so levelled that off to match the o/s.

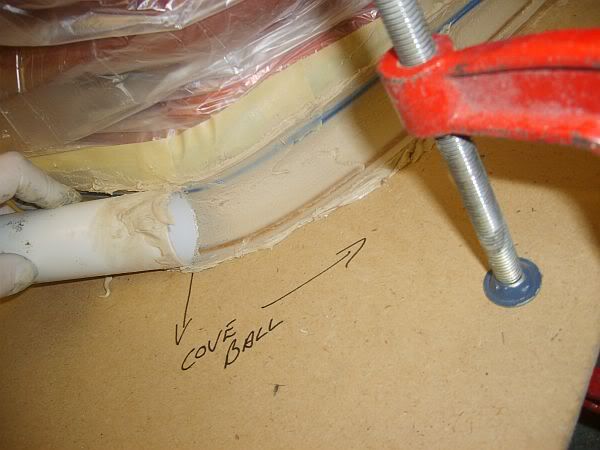

The gap at the front of the spoiler to the template is 40mm exactly and this will need to be filled in using body filler and a coving ball or something similar maybe the end of a silicone tube to get a nice even radius between the splitter and the spoiler itself.

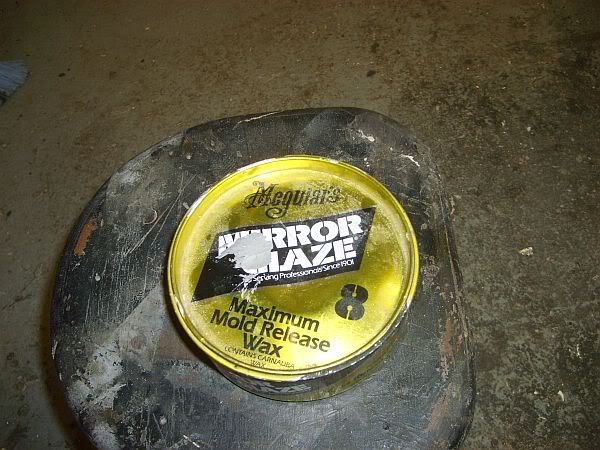

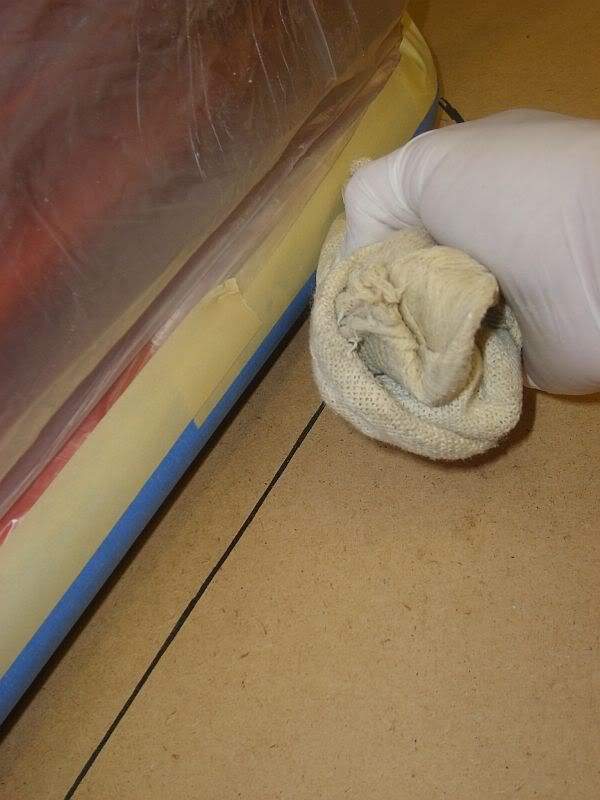

I will need to use low tack tape around the front of the spoiler so that when I use the mould release wax the filler once cured, will come away easily from the paint/tape without any damage and retain it's shape perfectly.

This will then give me my basis for the fibreglass mould I will make.

cheers

Paul