Oops, time for an update

I had a serious problem that caused much distress

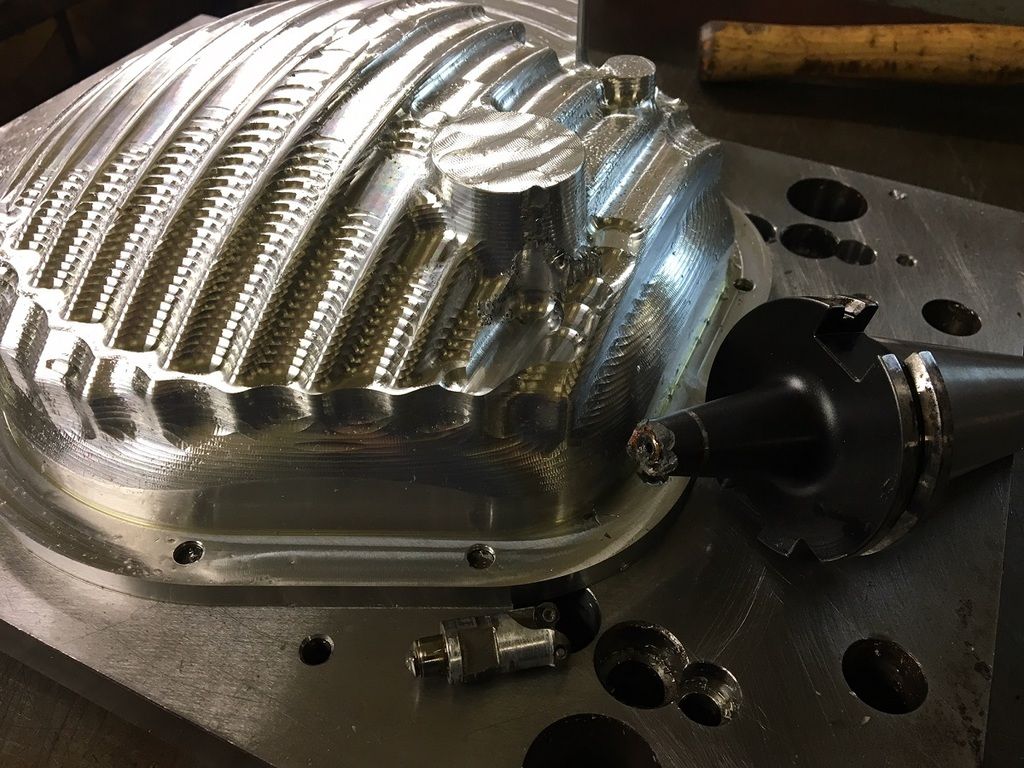

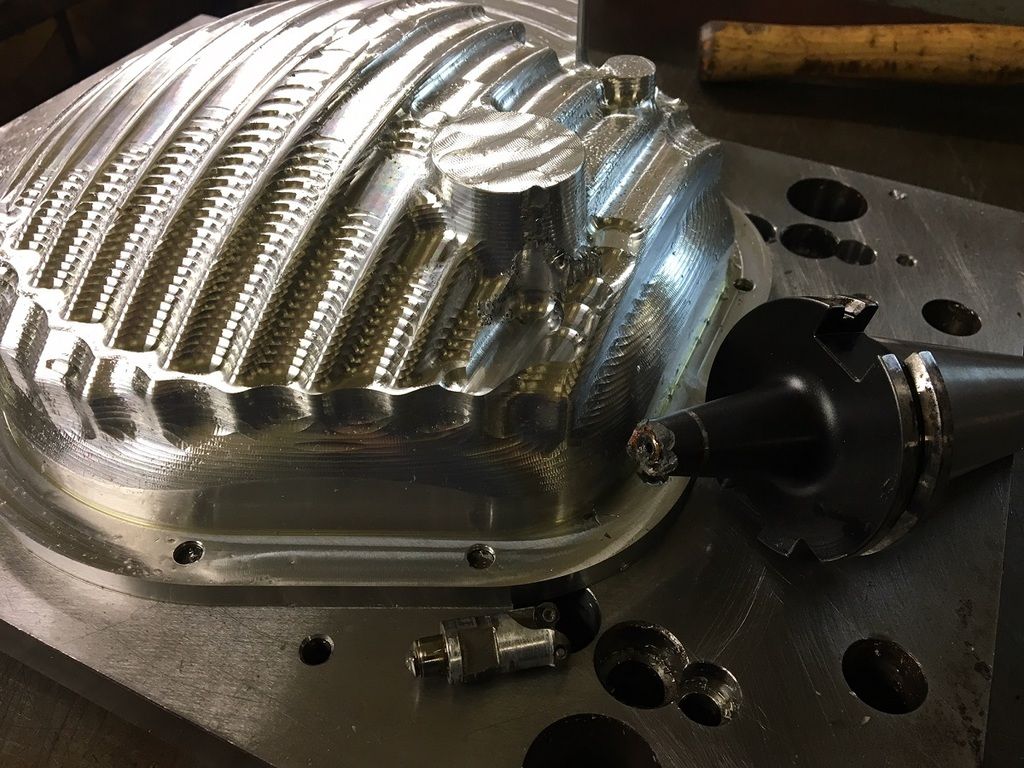

I'm still not sure if it was a post processor problem or a problem with the machining centre, but I poop my pants and the cutter got smashed to bits...

Plan B was a spot of weld to hide the damage, no more fins and a revised design machined on the small CNC at work instead - much slower, but up to this point it has not gone nuts

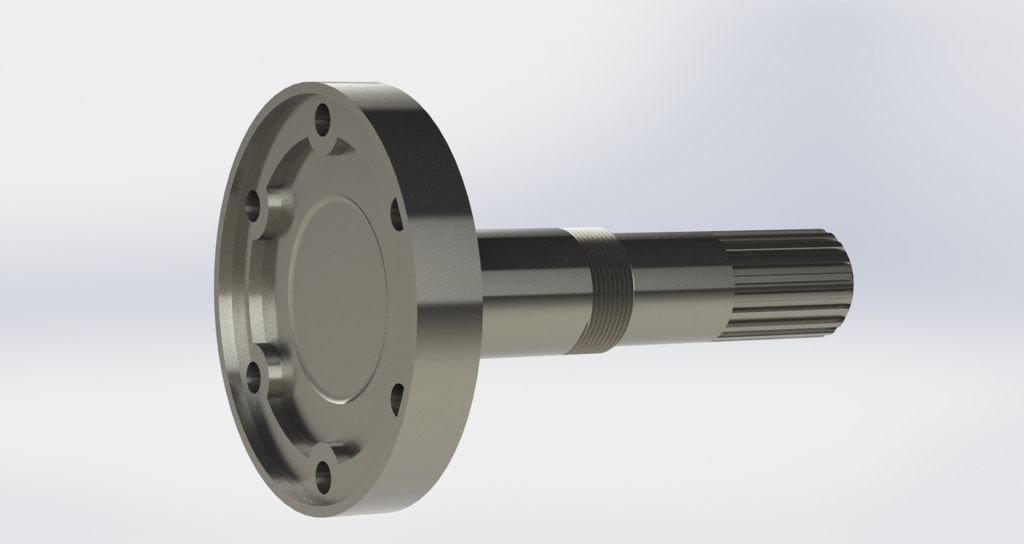

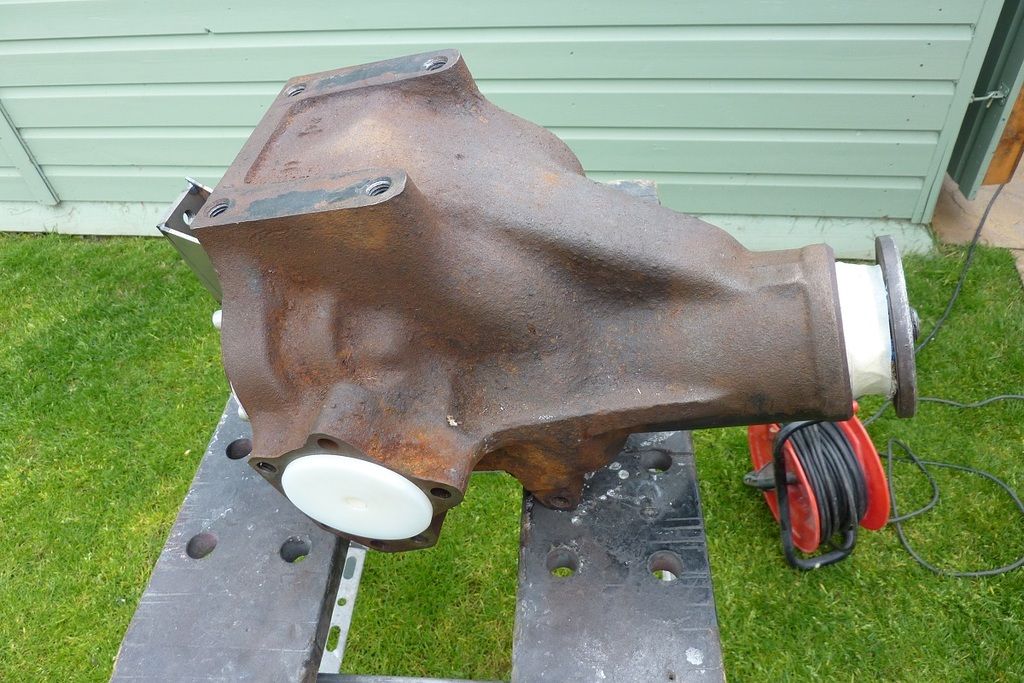

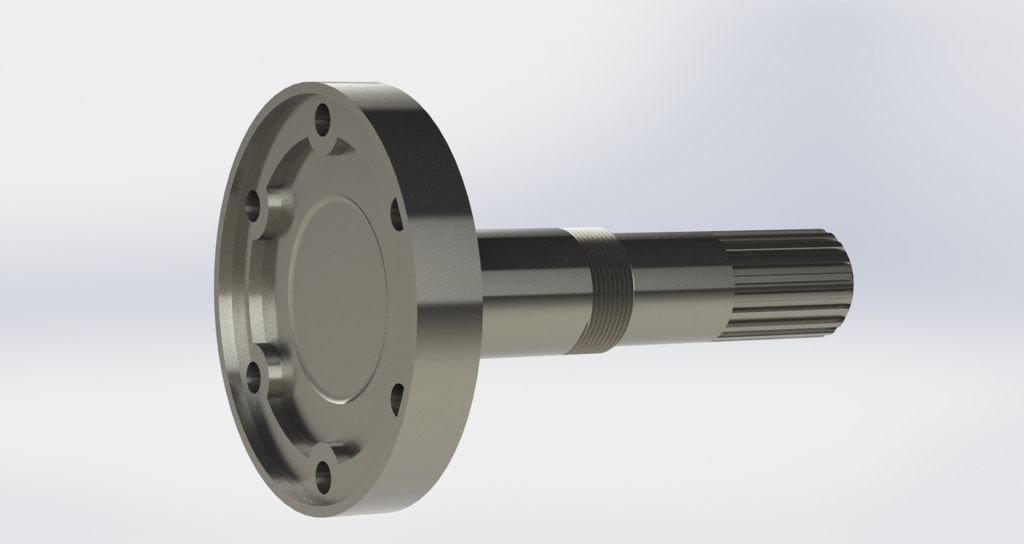

Drive shafts I have a plan for, stock Jag diff output shaft / stub axle

Some high tensile steel

Cunning plan for hybrid Cosworth / Jag set up.

The theory being I can just use standard Cosworth shafts - the Jag diff is a bit wider though which is a cause for concern.

A guy over on Passion ford assured me it will not be a problem as he did similar with a welded setup as pictured below using Jag and Cosworth bits.

I could have done the turning at work, but our lathe is knackered and I know a nice chap who works a CNC lathe...

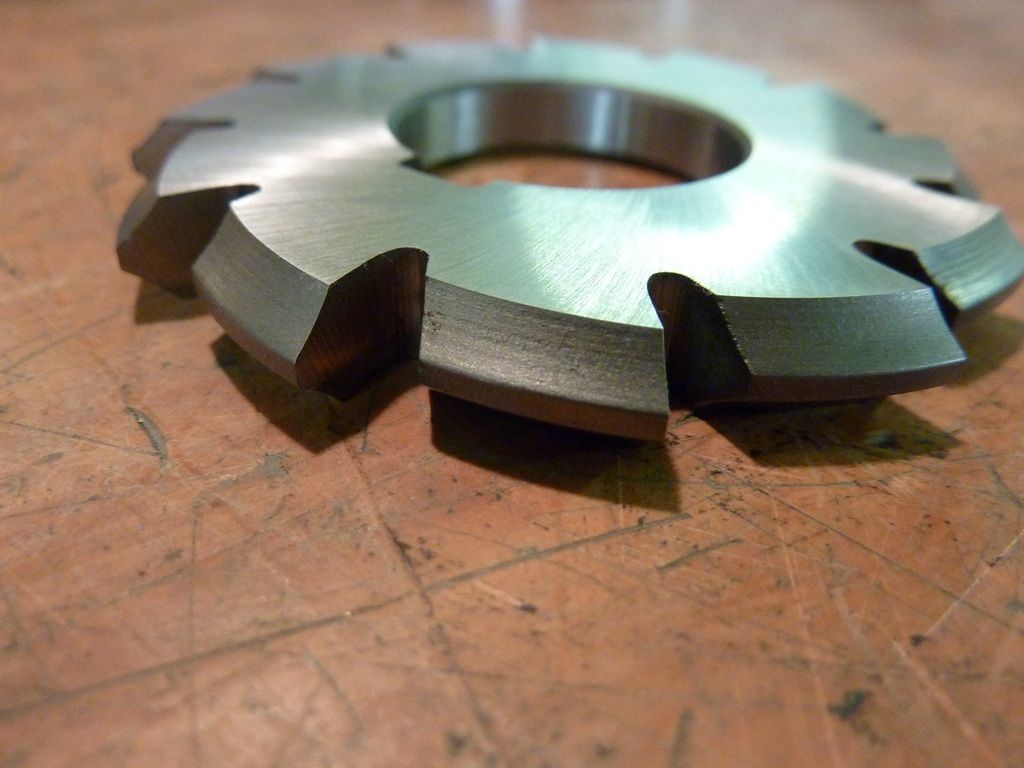

I had to get a spline cutter specially made - it's an involute form and I have no idea how to work that poop out !

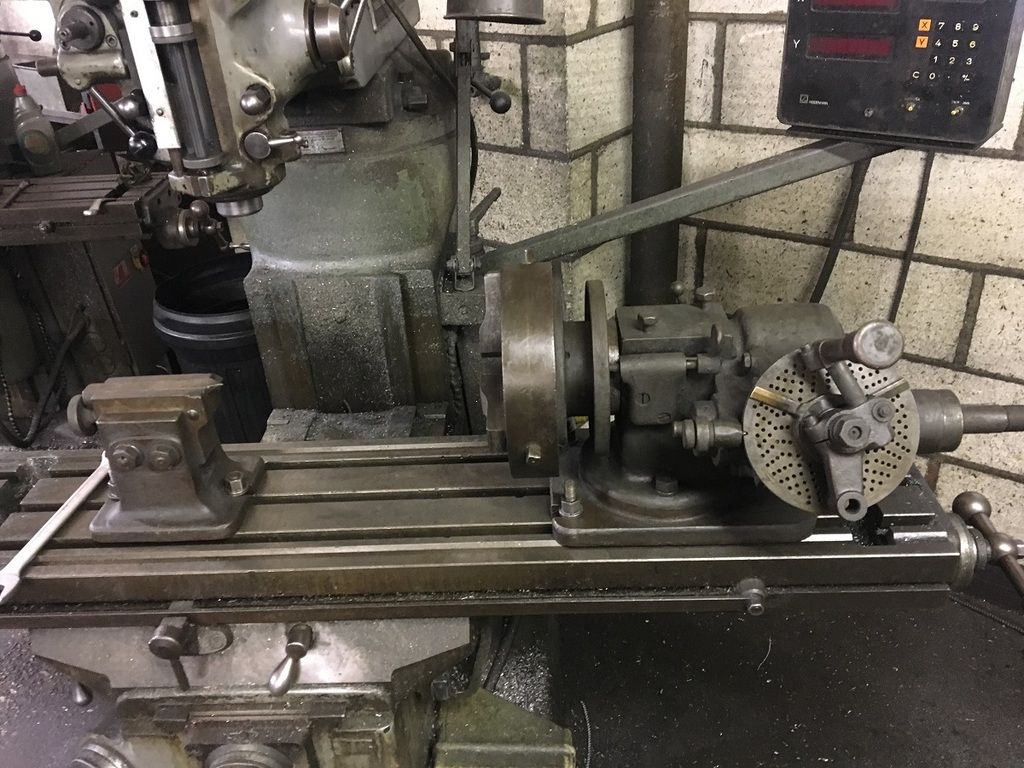

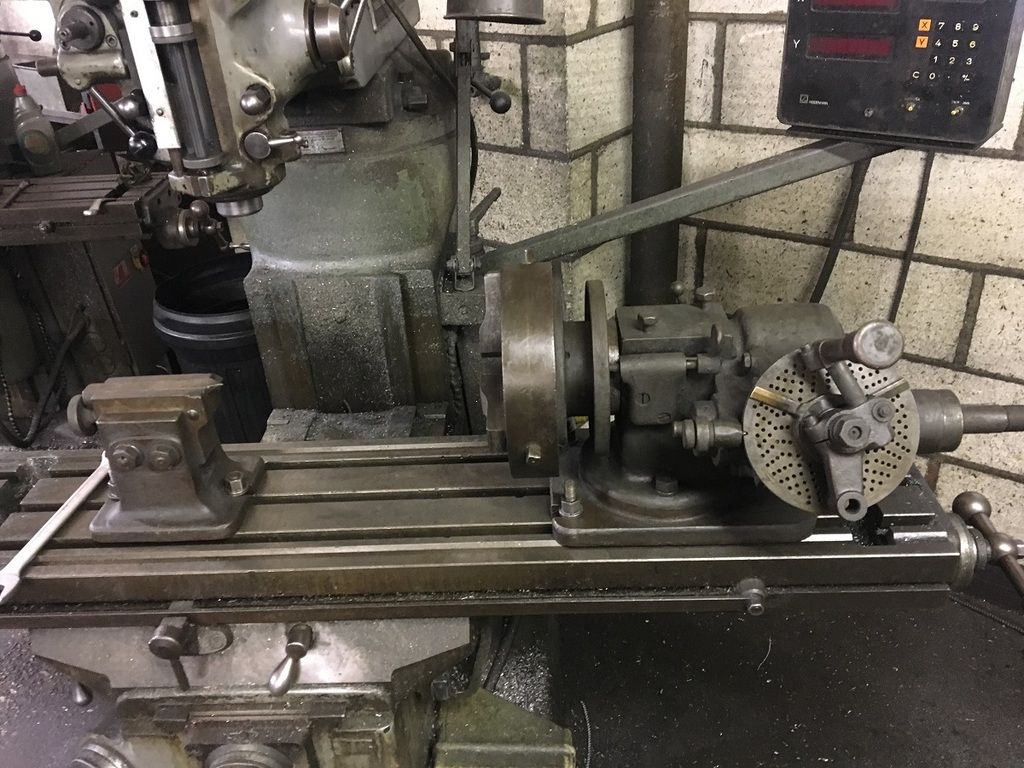

Plan was to cut the splines using our small dividing head, but the flange on the new stub axle is too big to fit - so I dug out the bigger dividing head that has been stat behind a surface grinder for a minimum of 20 years

After endless cleaning and blowing with the airline it was bolted to milling machine.

Now this would have been a great plan if I had bothered to check the hole circle on the big dividing head, it does not have the right amount of holes to give 19 splines / divisions.

Damn thing is now back behind the grinder and I'm making an adaptor to fit between the small dividing head and the new stub axle - watch this space !

Machining mounting for Cosworth 108mm shafts

That's it until I've been back into work over weekend ...

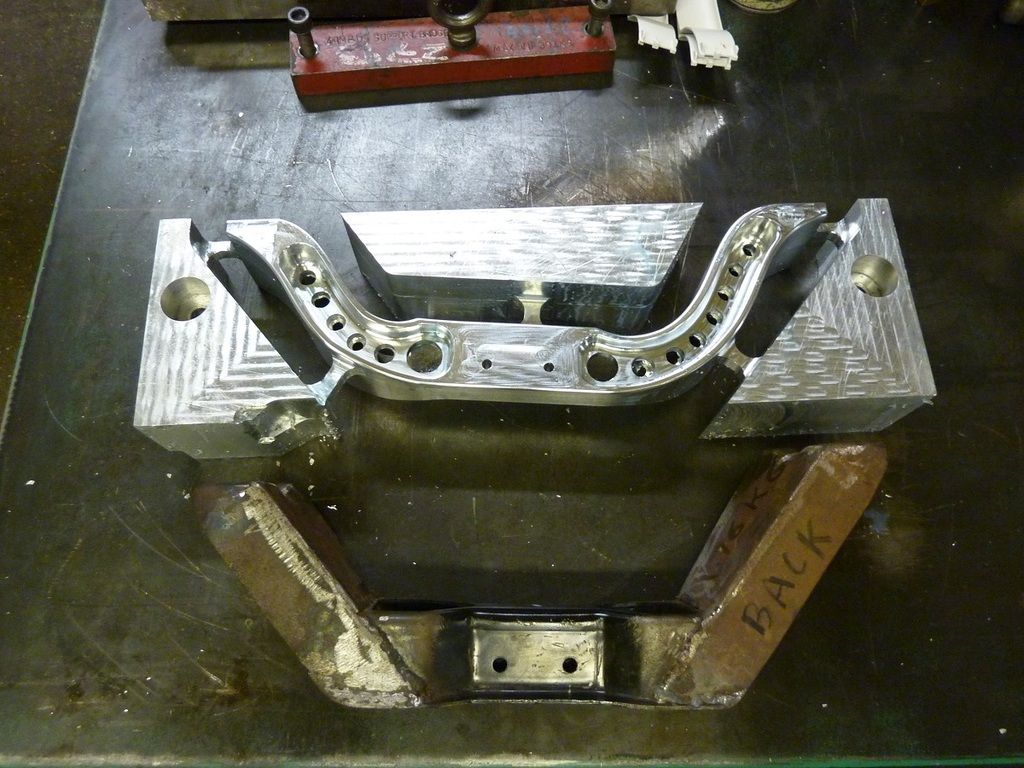

Drive shafts skimmed on the lathe to clean up

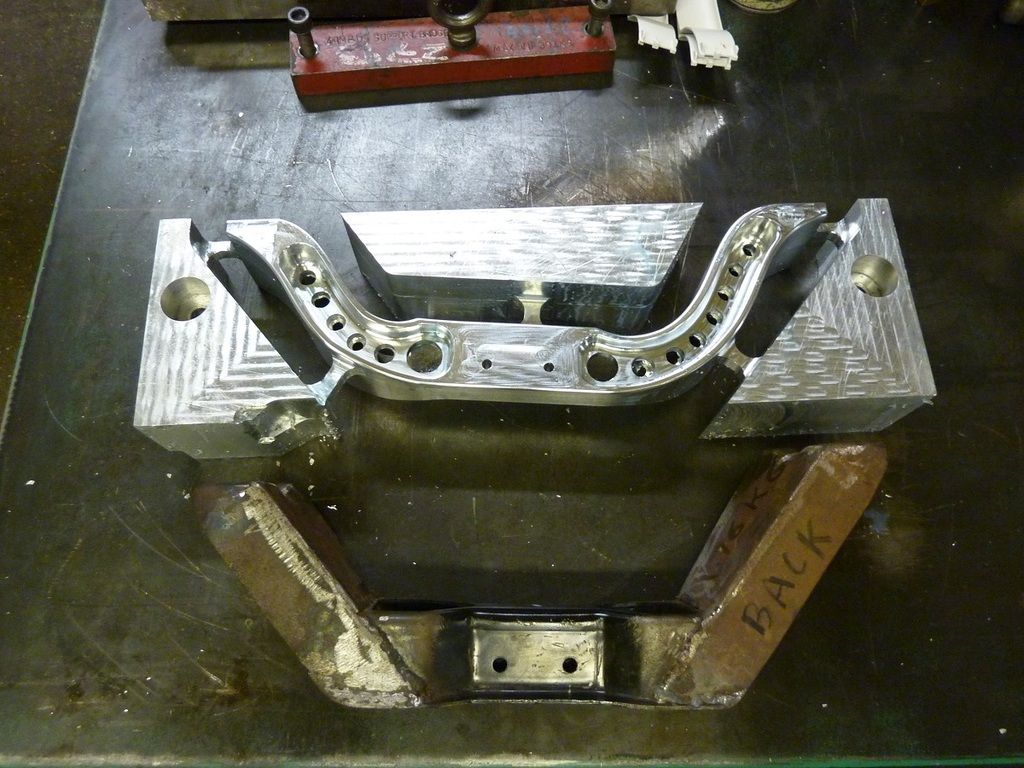

I never liked the gearbox cross member I fabricated, so went into work over Christmas and played - my daily driver not enjoying the cold !

Flipped to do other side

https://www.youtube.com/watch?v=n5CimGv87cE

https://www.youtube.com/watch?v=n5CimGv87cE

Bits back from anodising, bloody weld shows on diff cover though

That's it for now