Monkey business

Moderator: phpBB2 - Administrators

Making money out of your hobby is fine.

You are charging I hope?

Clearly what you are doing is good enough for folk to want so go for it.

If you need gear then please pm me and i will get prices and let you know.

It wont be any hassle for me as am at the local suppliers on a weekly basis sometimes daily!

Steve

masking tape is fine to work on as long as its good quality stuff and nit the pooh you get from B&Q etc.

3M tape is always the best to work from in my opinion as it never rucks up as the chemicals are curing.

Just gotta do the waxing as always OR PVA which I have used but am not a real fan of.

cheers

P

You are charging I hope?

Clearly what you are doing is good enough for folk to want so go for it.

If you need gear then please pm me and i will get prices and let you know.

It wont be any hassle for me as am at the local suppliers on a weekly basis sometimes daily!

Steve

masking tape is fine to work on as long as its good quality stuff and nit the pooh you get from B&Q etc.

3M tape is always the best to work from in my opinion as it never rucks up as the chemicals are curing.

Just gotta do the waxing as always OR PVA which I have used but am not a real fan of.

cheers

P

Unfortunately a lot of the photo's have gone from this thread - but this guy is a real fan of masking tape -  I buy mine form the local paint factors.

I buy mine form the local paint factors.

http://retrorides.proboards.com/thread/ ... 40?page=12

Thanks for the offer Paul I will drop you a PM.

At the moment I am only doing bits for a couple of very good friends and we have a reciprocal arrangement in place which you may be able to follow when I get around to writing up the engine build.

PVA does seems a bit marmite and previously I just used wax - up until I had a right nightmare with a part sticking to a mould.

I could never get and even coat with PVA nothing would work I tried thinning and spraying and all sorts and gave up with it. After that sticking issue a gave it go with the foam brushes and it flows out really nicely and always - belt and braces with it now - I am amazed at how strong it is with waxing and polishing it - but then a splash of water and its gone.

What the PVA has done for me on these parts is meant I do zero panel prep - just PVA and wax - the moulds will copy every flaw but as they will be used to repair damaged parts in situ and the panels will need prep and paint the finish is secondary

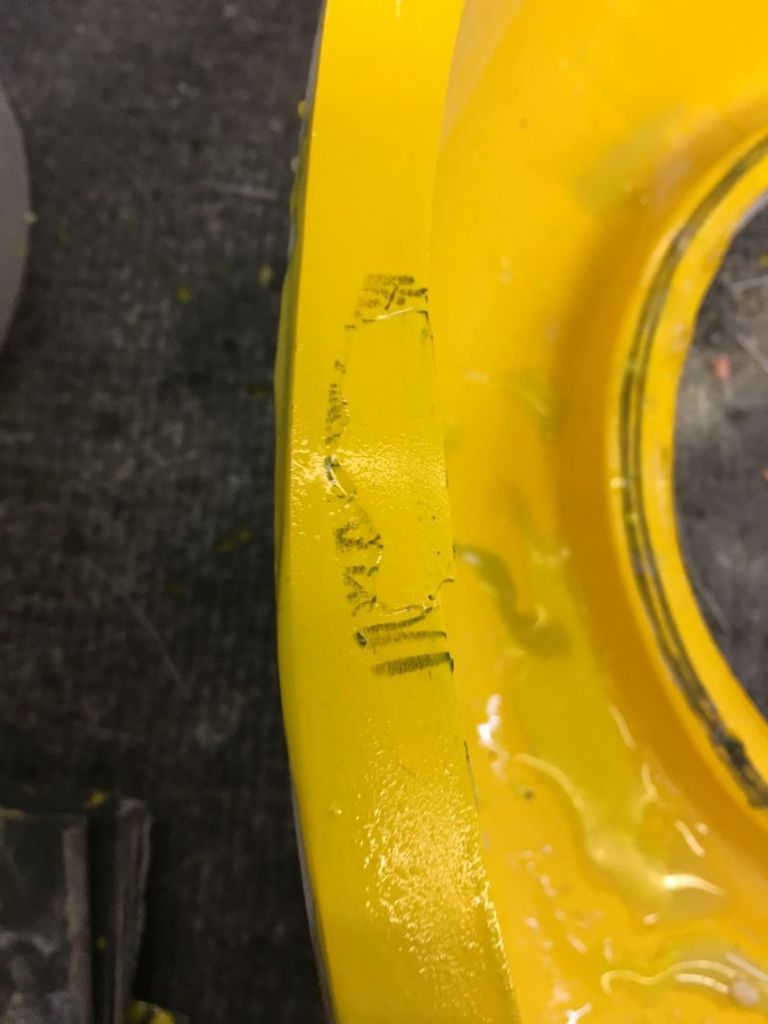

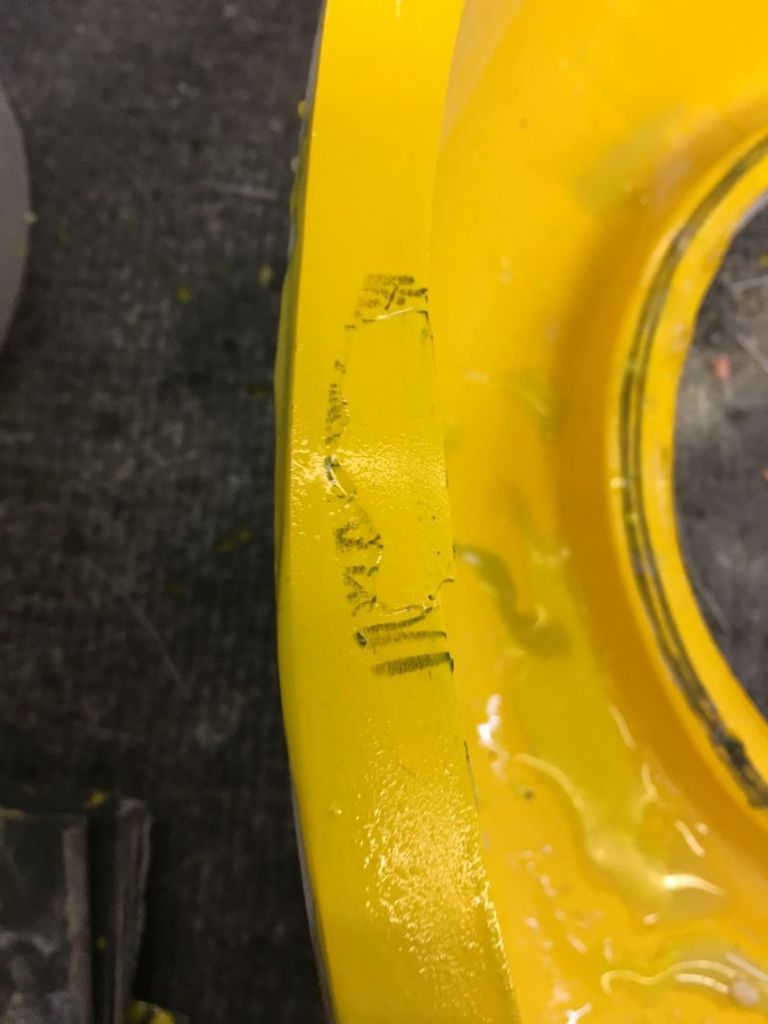

They have been produced to repair this. And figured I would make a couple of rear wing/arch panels at the same time as many of the cars were modified for wide arches but are now more valuable stock.

http://retrorides.proboards.com/thread/ ... 40?page=12

Thanks for the offer Paul I will drop you a PM.

At the moment I am only doing bits for a couple of very good friends and we have a reciprocal arrangement in place which you may be able to follow when I get around to writing up the engine build.

PVA does seems a bit marmite and previously I just used wax - up until I had a right nightmare with a part sticking to a mould.

I could never get and even coat with PVA nothing would work I tried thinning and spraying and all sorts and gave up with it. After that sticking issue a gave it go with the foam brushes and it flows out really nicely and always - belt and braces with it now - I am amazed at how strong it is with waxing and polishing it - but then a splash of water and its gone.

What the PVA has done for me on these parts is meant I do zero panel prep - just PVA and wax - the moulds will copy every flaw but as they will be used to repair damaged parts in situ and the panels will need prep and paint the finish is secondary

They have been produced to repair this. And figured I would make a couple of rear wing/arch panels at the same time as many of the cars were modified for wide arches but are now more valuable stock.

4.5L V8 Ginetta G27

I am going to apologise again as I am making too many posts on your thread and it has been so usefula and informative - I read avidly the Front spoiler thread the Sligshot thread and this as they are so full of useful advice.gelmonkey wrote:Andrew ....

If using the tape to hold the cardboard in place then why not use hot glue instead and then just soak it with acetone when ready to remove as this chemical makes the glue very brittle and it just falls off.

The other thing I noticed in your previous post was no cradle on the bumper mould unless it cannot be seen from the angle of the picture.

A small simple cradle would help stop the mould from moving around as you worked on it.

Again just a thought and PLEASE correct me if Im wrong

When the new glue gun arrives I will give it a go.

You are correct - no cradle on those moulds - I did think about it, but I was doing all of these six moulds at the same time all in a bit of a hurry. I plan to knock up a little wooden cradle and just PU sealer it to the mould.

As this is a bit of an experiment its far from perfect - if It does work out I have no doubt I will doing a small production run. The rear bumper is another matter and I will be revisiting the slingshot thread for some tips with that.

Again sorry for the diversion and many thanks

Andrew

4.5L V8 Ginetta G27

Hell of a lot of work going into that project for sure.

Maybe a bit to much masking tape for my liking but then thats just my opinion and not saying its wrong.

Also and again in my opinion there are far too many square joints going on in there as these will give rise to crack points that could have serious repercussions a bit further down the line.

Whilst making any structural unit it is ALWAYS best to have as few joints as possible and also to feather the laminates out so that the loads are spread.

As a keen enthusiast I cannot find anything you are doing wrong with your projects and once you have sent me a pm I will give you both of my numbers and Email address so if you have any questions you can either phone or mail me and i will hopefully be able to talk you through whatever you are trying to do.

With your splash mould fixings onto the wing if you dip the screws into wax and then fix you can glass straight over the top and then remove them once the laminates have cured .

All you need then is just a single layer closing laminate and jobs a good un

P

Maybe a bit to much masking tape for my liking but then thats just my opinion and not saying its wrong.

Also and again in my opinion there are far too many square joints going on in there as these will give rise to crack points that could have serious repercussions a bit further down the line.

Whilst making any structural unit it is ALWAYS best to have as few joints as possible and also to feather the laminates out so that the loads are spread.

As a keen enthusiast I cannot find anything you are doing wrong with your projects and once you have sent me a pm I will give you both of my numbers and Email address so if you have any questions you can either phone or mail me and i will hopefully be able to talk you through whatever you are trying to do.

With your splash mould fixings onto the wing if you dip the screws into wax and then fix you can glass straight over the top and then remove them once the laminates have cured .

All you need then is just a single layer closing laminate and jobs a good un

P

Evening everyone and especially for Andrew .

This is how the small repairs are dealt with.

There were a small amount of gel repairs to deal with so satrting with the biggest one first.

The edges are chamferred back with a stanley knife and then cleaned out with acetone.

It is important to make the edges slightly bevelled as this gives the gel something to grab to as it cures and a sharp edge will never give a proper repair.

Once this has been done masking tape is placed over the repair site like this.

Then it s a case of mixing the gel up and letting the gel in with a wooden tongue depressor.

You can use anything with a point on it to put the gel in as long as its clean.

I peel the tape back and start at the bottom and then draw the tape up to hold the gel in place something like this.

Once the vertical side is done then you can just top the repair up from the top.

The rest of the repairs are done just the same but if very small you can just let the gel in without the tape.

All of this now needs to cure for about 24 hrs so I will probably get back to this on Monday evening.

Hope this helps Andrew?

cheers

P

This is how the small repairs are dealt with.

There were a small amount of gel repairs to deal with so satrting with the biggest one first.

The edges are chamferred back with a stanley knife and then cleaned out with acetone.

It is important to make the edges slightly bevelled as this gives the gel something to grab to as it cures and a sharp edge will never give a proper repair.

Once this has been done masking tape is placed over the repair site like this.

Then it s a case of mixing the gel up and letting the gel in with a wooden tongue depressor.

You can use anything with a point on it to put the gel in as long as its clean.

I peel the tape back and start at the bottom and then draw the tape up to hold the gel in place something like this.

Once the vertical side is done then you can just top the repair up from the top.

The rest of the repairs are done just the same but if very small you can just let the gel in without the tape.

All of this now needs to cure for about 24 hrs so I will probably get back to this on Monday evening.

Hope this helps Andrew?

cheers

P

Evenin all

Well I was trying to get this up last night but photobucket was having none of it so hopefully tonight will be better.

Before I put the pics up it would be worth noting that an awful lot of the time people dont think that the gel has gone off because its still sticky and I would not mind a pound for every time it has been mentioned to me thats for sure.

If you have mixed the gel and the catalyst properly and its gone off in the pot then it will have gone of at the repair site.

The reason that it is sticky is because a chemical called styrene has risen to the surface of the gel to provide a chemical key for the next application of gel if there needs to be one.

The sticky makes folk think it has not cured but a quick wipe over the repair site with acetone and the stickiness has gone.

So with that all in mind I have already wiped the small repairs down prior to flatting back.

I generally start rubbing own with 400 after scribbling over the 'fill ' with a chinagraph pencil.

The pencil is my guide coat and it one of the most important tools in our arsenal.

With plenty of water i just sand away trying to give myself a reasonable 'throw' on the block as this keeps the surrounding area of the repair site nice and flat too.

Always try to use a block when flatting back as by just using your finger you will without question get train tracks in the surrounding areas of the repair and you wont get a flat repair either

Once you think you have it fairly flat then chinagraph up again and you will be surprised at how much you have'nt got it flat.

This is greatly exagerated here for you to see and no my eye sight is not that bad thank you and yes I know this is a different repair site to the first one but who cares

If you think you are ready to go down a grade ie onto 1200 then go for that and repeat until there are no black lines at all.

Then one final pass with the chinagrpah and a rub over with 12 and if all is good then you can move onto the next repair.

I am now at the stage where all of the small repairs have been rubbed down in the top section and am going over the whole thing with chinaagraph 400 and then 1200 prior to a good polish up.

As time is limited this week I may or may not get this all finished by Friday.

Any questions?

cheers

P

Well I was trying to get this up last night but photobucket was having none of it so hopefully tonight will be better.

Before I put the pics up it would be worth noting that an awful lot of the time people dont think that the gel has gone off because its still sticky and I would not mind a pound for every time it has been mentioned to me thats for sure.

If you have mixed the gel and the catalyst properly and its gone off in the pot then it will have gone of at the repair site.

The reason that it is sticky is because a chemical called styrene has risen to the surface of the gel to provide a chemical key for the next application of gel if there needs to be one.

The sticky makes folk think it has not cured but a quick wipe over the repair site with acetone and the stickiness has gone.

So with that all in mind I have already wiped the small repairs down prior to flatting back.

I generally start rubbing own with 400 after scribbling over the 'fill ' with a chinagraph pencil.

The pencil is my guide coat and it one of the most important tools in our arsenal.

With plenty of water i just sand away trying to give myself a reasonable 'throw' on the block as this keeps the surrounding area of the repair site nice and flat too.

Always try to use a block when flatting back as by just using your finger you will without question get train tracks in the surrounding areas of the repair and you wont get a flat repair either

Once you think you have it fairly flat then chinagraph up again and you will be surprised at how much you have'nt got it flat.

This is greatly exagerated here for you to see and no my eye sight is not that bad thank you and yes I know this is a different repair site to the first one but who cares

If you think you are ready to go down a grade ie onto 1200 then go for that and repeat until there are no black lines at all.

Then one final pass with the chinagrpah and a rub over with 12 and if all is good then you can move onto the next repair.

I am now at the stage where all of the small repairs have been rubbed down in the top section and am going over the whole thing with chinaagraph 400 and then 1200 prior to a good polish up.

As time is limited this week I may or may not get this all finished by Friday.

Any questions?

cheers

P

You provided the answer I was going to have on the gel being sticky - sorted.

I was giving the bumper mould a once over today with some 800 - telling those chips I would have them resolved shortly once the masterclass had resumed.

In the past I have sealed the gel under cellophane sometimes the surface hardened another time it didn't ! - I bought a pot of top coat for gel repair to see if its better but have not had the opportunity to use it yet.

I am looking forward to making the mould for the next project as I have picked up so many area's where I need to do things differently.

Later in the year I have a bigger project - The entire front end bonnet on my G27 - once I have decided on the front light design - and some major re-modelling of the rear of the car and the arches. I will seeking your advice on that those for certain.

Whilst on advice - body panel flash line removal - 400 / block and the chinagraph? finer grade and polish - gel is the final finish on this one - there are not a huge amount thankfully.

Andrew

I was giving the bumper mould a once over today with some 800 - telling those chips I would have them resolved shortly once the masterclass had resumed.

In the past I have sealed the gel under cellophane sometimes the surface hardened another time it didn't ! - I bought a pot of top coat for gel repair to see if its better but have not had the opportunity to use it yet.

I am looking forward to making the mould for the next project as I have picked up so many area's where I need to do things differently.

Later in the year I have a bigger project - The entire front end bonnet on my G27 - once I have decided on the front light design - and some major re-modelling of the rear of the car and the arches. I will seeking your advice on that those for certain.

Whilst on advice - body panel flash line removal - 400 / block and the chinagraph? finer grade and polish - gel is the final finish on this one - there are not a huge amount thankfully.

Andrew

4.5L V8 Ginetta G27

-

unstable load

- Top Dog

- Posts: 1285

- Joined: Mon May 04, 2009 6:53 am

- Ian Anderson

- Forum Contributor

- Posts: 2458

- Joined: Sun Nov 19, 2006 9:46 pm

- Location: Edinburgh

unstable load wrote:Can't you stick the lights in the already there holes adjacent to the radiator opening? It seems like they are there for lights before the designer had a brain fart and made the pop-up lights.

My guess they would be too low to meet SVA or IVA regulations

Ian

Owner of an "On the Road" GT40 Replica by DAX powered by 3.9Hotwre Efi, worked over by DJ Motors. EFi Working but still does some kangaroo at low revs (Damn the speed limits) In to paint shop 18/03/08.

Nah. Pop-ups were almost a Bertone trade mark in the 70's and I happen to love them. Every "fun" car I have has pop-ups !! even the ones without concealed lights.unstable load wrote: Can't you stick the lights in the already there holes adjacent to the radiator opening? It seems like they are there for lights before the designer had a brain fart and made the pop-up lights.

But design aspects of 60's and 70's classic cars is probably a subject for a different thread.

4.5L V8 Ginetta G27

Hi all and particularly Andrew

Topcoat for repairs NO NO NO NO NO AND THEN NOOOOOO.........

Reason is simple

Topcoat sometimes known as flowcoat has a wax added to it so that once cured the surface is not sticky and is and should only be used as a final coating for bare laminates.

Remembering the repairs just recently shown and discussed the stickiness (styrene) is the chemical part of the gel coat that helps in adhesion for second or third applications and also helps to 'bite' into the external edges of a repair site which helps it to stay in place.

Topcoat is exactly the same as gel but has a chemical called a Styrene Monomer added to kill the sticky bit.

Whilst you could do a repair with it it WILL FAIL and in short order too and should only be used as a last resort .

Did I mention that you should not do repairs with topcoat ?

?

With regard to the flash lines I would be having a good look at the thickness of the gel prior to any sanding back as sometimes it is very thin and you wont have much to work with once sanding has started.

Also depending on the colour of the gel it may be that you will have to go down as fine as 2000 grit before polishing as the darker the gel the more the sanding marks will show when polished.

If a light colour is being used then you could most probably finish on 1200 and then give it a really good machine polish.

I will talk to you a little closer to the time about compounds and polishing because as always there are good and bad products (in my opinion) along with the right and wrong way to polish (again in my opinion)

With regard to advice on the restyle later in the year I will be more than happy to help you and anyone else with hands on help if required or just a chat down the phone if that is all that is needed.

Never a problem for anyone on here.

cheers

Mr Dont use topcoat for repairs

Topcoat for repairs NO NO NO NO NO AND THEN NOOOOOO.........

Reason is simple

Topcoat sometimes known as flowcoat has a wax added to it so that once cured the surface is not sticky and is and should only be used as a final coating for bare laminates.

Remembering the repairs just recently shown and discussed the stickiness (styrene) is the chemical part of the gel coat that helps in adhesion for second or third applications and also helps to 'bite' into the external edges of a repair site which helps it to stay in place.

Topcoat is exactly the same as gel but has a chemical called a Styrene Monomer added to kill the sticky bit.

Whilst you could do a repair with it it WILL FAIL and in short order too and should only be used as a last resort .

Did I mention that you should not do repairs with topcoat

With regard to the flash lines I would be having a good look at the thickness of the gel prior to any sanding back as sometimes it is very thin and you wont have much to work with once sanding has started.

Also depending on the colour of the gel it may be that you will have to go down as fine as 2000 grit before polishing as the darker the gel the more the sanding marks will show when polished.

If a light colour is being used then you could most probably finish on 1200 and then give it a really good machine polish.

I will talk to you a little closer to the time about compounds and polishing because as always there are good and bad products (in my opinion) along with the right and wrong way to polish (again in my opinion)

With regard to advice on the restyle later in the year I will be more than happy to help you and anyone else with hands on help if required or just a chat down the phone if that is all that is needed.

Never a problem for anyone on here.

cheers

Mr Dont use topcoat for repairs

-

stevieturbo

- Forum Contributor

- Posts: 4075

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland