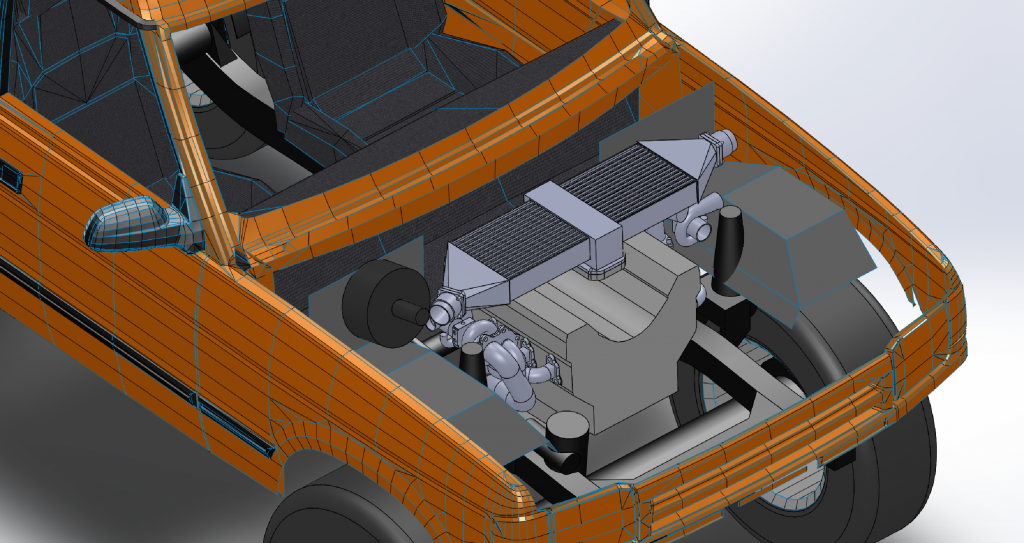

v8250 wrote:Stirling, that's some serious work going on there...it's not an ideal design but I see no reason why it should not work with correct tweaking. Here are some notes that I hope will help.

Thank you for you very constructive feedback Andrew!

v8250 wrote:1. Are you having open vents above/near the TMIC fans? If not, do consider this for heat extraction and/or cool air induction; are the fans suckers or blowers?

Absolutely going to have the fans sucking fresh air from a large scoop on the bonnet. They are set up in a pusher configuration. In a sucker configuration they would have acted as s heaters!

v8250 wrote:2. As others have rightly said, heatsoak is going to be the biggest challenge. To aid heatsoak control be sure to insulate the exhaust manifolds with a good proven material. I can recommend Thermal Velocity's Magma Wrap, it's exceptionally good product.

http://www.thermalvelocity.co.uk/produc ... =&P_ID=408

Thanks for the recommendation, I used to/still work for a company that designs and builds exhaust systems for large industrial gas turbines so I was thinking of getting my hands on some ceramic fibre and glass fibre woven blanket and thermally insulating everything I could. By making my own blankets.

v8250 wrote:3. The TD04's are a good choice, readily available and relatively under stressed units...I have one on my Forester XT and they're good for 270bhp on a baby 2.5ltr flat four. Again, heat control is key here so blanket wrap these with good quality turbo blankets.

I spent a lot of time trying to work out which turbo to use, so good to hear that they are reliable!

Thanks, I'll keep them in mind.

v8250 wrote:5. Thermal dissipation and its control is key. If possible, be sure to have greater air exit volume than air intake volume within the engine bay. This is particularly important at the rear of engine bay leading into the gearbox tunnel. The trick is to reduce high pressure build areas as much as possible...run some rough calcs which will give you a benchmark to work from...then, if necessary reposition some wing mounted items to aid better flow and/or add extra air escape routes to rear of engine bay.

Definitely something to keep in mind, thing is, the time when the engine will have most load on our is when the car is travelling slowly. Putting in some vents would do no harm. I could run a Cfd model to find where low pressure zones are for venting.

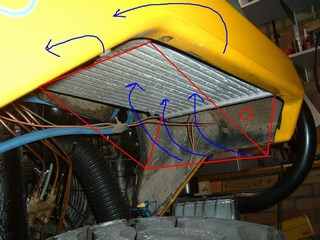

v8250 wrote:6. We can assume you've carefully chosen your radiator...if not, oversize the water volume by 25-30% and then add sucker radiator fan/s. Oh, and although alloy rads are lighter and look good they are far poorer at thermal transfer so go along to your local radiator man and get a good old fashioned copper core with max' sized/straight upper and lower brass headers.

The radiator is yet to be purchased, using the stock radiator for now for using. I have remote fan forced oil coolers under the tray for cooling of engine oil and transmission oil. I was starting to be tempted with those aluminium aluminium radiators so I really appreciate the heads up on them!

v8250 wrote:Good luck with the project...btw, what's the expected power output?

I'm aiming for around 400hp I think?