Pauls - thread - http://www.v8forum.co.uk/forum/viewtopi ... &start=120

The second try on the bumper repair turned out a little better and hopefully tomorrow that will sand back as well as Pauls repairs.

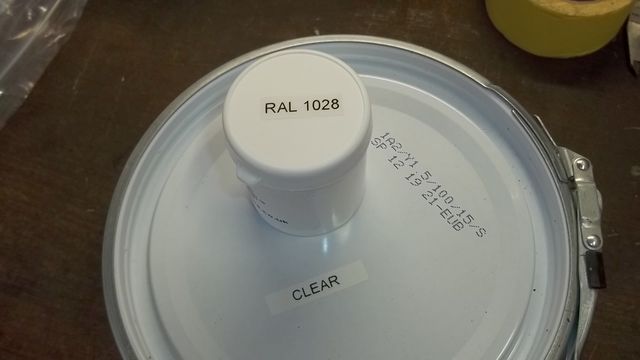

I also thought I would try mixing some clear gel and colour - Ral 1028 Melon Yellow which is the same colour as the Strat. and then make up a small test panel for what I am considering for the bumpers to be made in the green moulds.

If this stuff is good enough for the Pro then its good enough for me.

I realise that this is a bit of a departure from air inlet filter plenum but hopefully if you fancied making an air inlet cap etc. that as well as Paul's great advice on how to do it my mishaps mistakes and diversions may be of some assistance.

Clean PVA and a couple of coats of wax - must be getting better with the PVA as it went on a dream.

Mixing up coloured gel is pretty simple - buy some clear buy some pigment from the range of colours and follow the instructions - in this case 15% by weight

Slap it onto your mould

I only did one single thick lumpy coat and 2-3 even coats is the way to go for a good finish which I am sure Paul will cover when he makes the piece when the mould is complete.

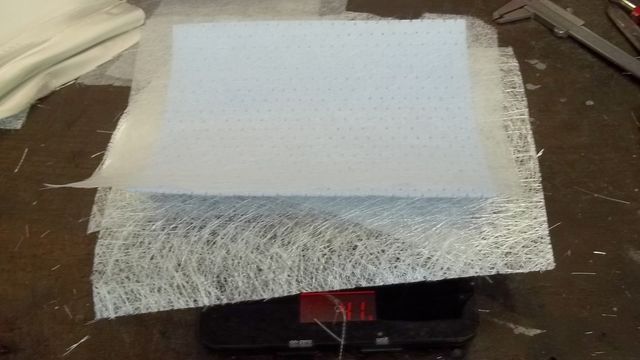

I wanted to lay up a panel no thicker than the bumper itself at about 1.5mm but with a decent amount of strength

To be the same bending strength as steel a standard glass composite needs to be about 2.5 times thicker and at that its only 60% of the weight.

I decided to use statin cloth in the laminate as this is stronger than CSM and takes less resin reducing the weight but with better strength

225g matt and 288g stain weave glass and some surface - These will be the components of the laminate

gel/tissue/225/288/225 the glass

This measures at 0.8mm with vernier and should with the resin swell to around 1mm and with 0.5mm of gel give me the 1.5mm panel I am after.

I also wanted to see just how little resin I would need to use to full wet out the panel - The tissue and the cloth take very little resin and the 225 wets out very easy so I measured for 2 x the weight - usually I weigh 2.5 to make sure I have enough but with the brush wicking method from Paul I was certain x 2.0 would have loads to spare as the cloth is typically 1:1.

The cloth weighed around 38g for the test panel - there is a bit of core mat thrown on top of this shot which is for another test.

After the gel had done its things I set to laying up and was amazed at how little resin I use to wet it out - especially the cloth as this just seemed to wick the resin from the CSM as soon as it was laid - I guess as there is no need to break down and binders it just absorbs like a sponge and in no time at all it was virtually invisible. on with the next layer of 225g CSM and wet that out and then on to seeing how much resin I could pull from the laminate with the brush wicking whilst making sure it was all fully wetted.

After working the laminate and wicking out the resin I managed to have quite a bit of resin left in the pot and weighing up after I estimate that I have used about 55g of resin for around 33g of glass or a resin ratio of 1.6

The cloth is really nice to work with very pliable and soft.

Should be in a position tomorrow to see how it tuned out and what sort of strength it has being so thin.

Andrew