It was way to cold to work out on site today so it was decided to come back home and work on Mikes mould again.

It has been 0 degrees in the workshop all day but we knew that we could work at releasing the main body section without worrying about cure rates etc.

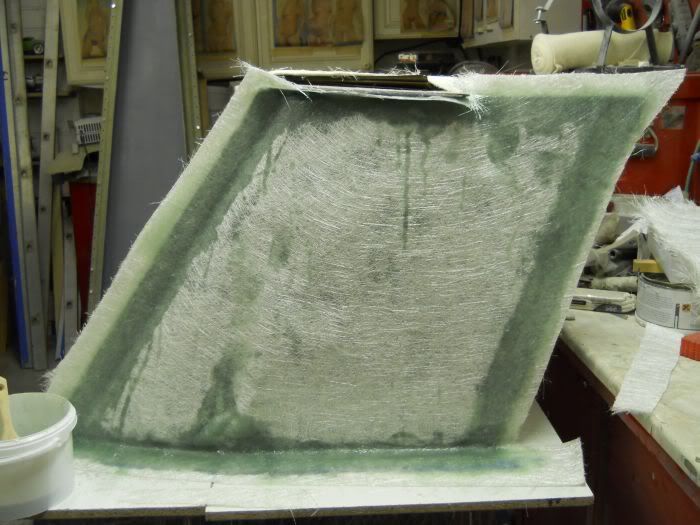

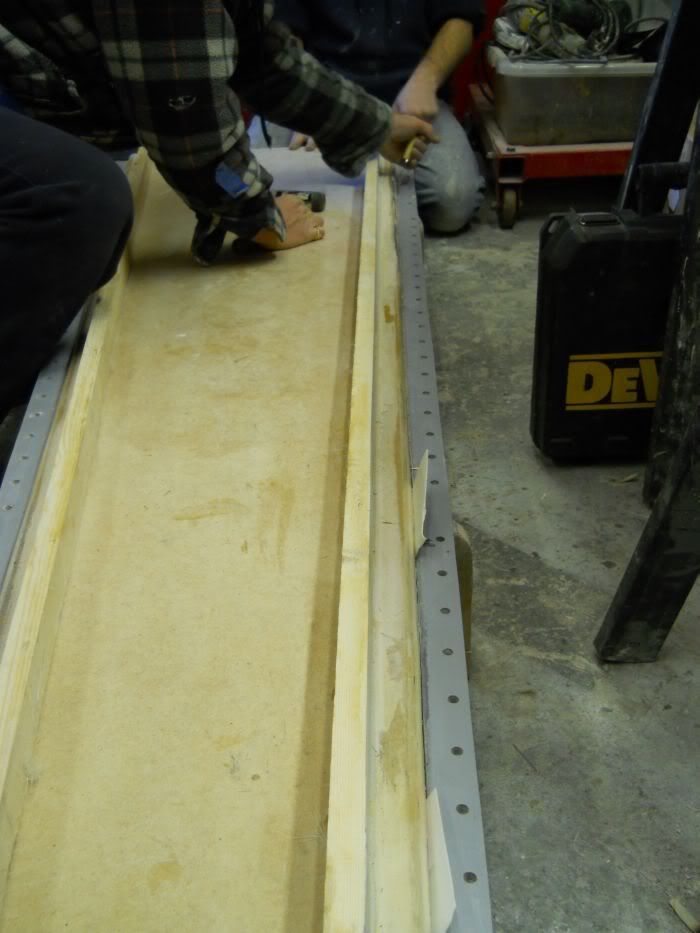

So,after drilling a few 8mm holes for the bolts to hold the mould together a bit further down the road we ended up with this.

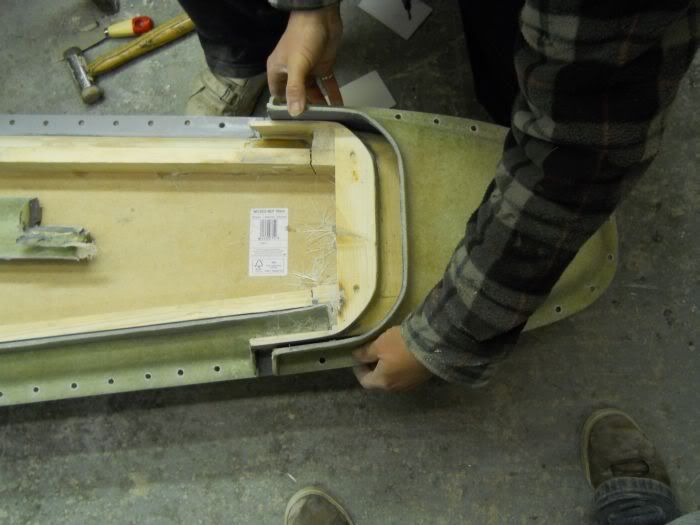

The bolt spacing was worked out at 2" apart all the way around as this will give a very even clamp load to the fences and will combat any distortion that tries to take place during cure.

Next armed with a small scraper and a whole pile of filler spreaders it was on to releasing or not as the case may be.

Slip the scraper and then the speaders in,pull through and if we are lucky a section will come of!

Ok that bit done the next thing to do was the side rails and the remainder of the nose cone.

Fingers crossed

All going well so far and reasonably happy with the release we came to the main section.

For those of you who have followed along with this project you may remember a point about curing and shrinkage when glssing a while back and this was going to be a major factor as we were going to find out.

Mike made his plug with balsa wood,MDF and some lengths of 2x1 timber and covered it all with a shellack based sealer.

Balsa is soft as we know and as the gel and glass had cured it pulled in really tight to the form.

Add to that the quite cold conditions in the workshop and we were faced with a bit of a challenge as the mould had shrunk a little as well.

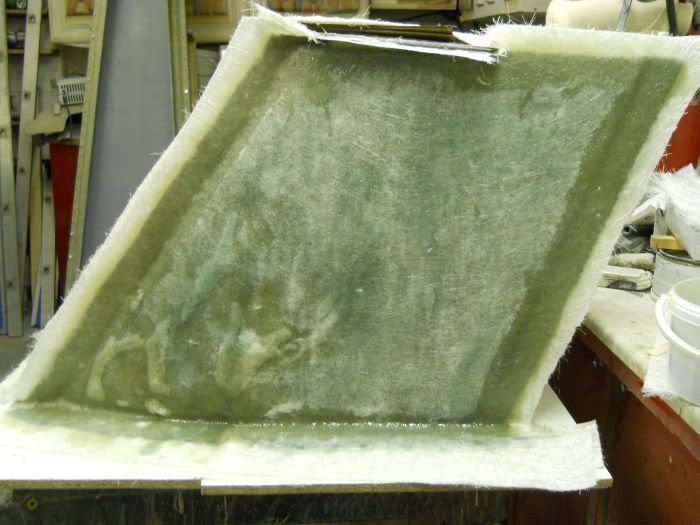

Spreaders pushed in and pulled through and maybe the odd naughty word here and there the main section put up a fight.

We could hear the sides releasing but the main bulk would not 'pop'.

More spreaders and a bit more 'oomph' and finally we had the pop but it was'nt the pop of the mould releasing it was the curved skin of the plug coming away from the body and you can see this clearly in the next pic.

Sorry Mike but you wont be using that for anything again.

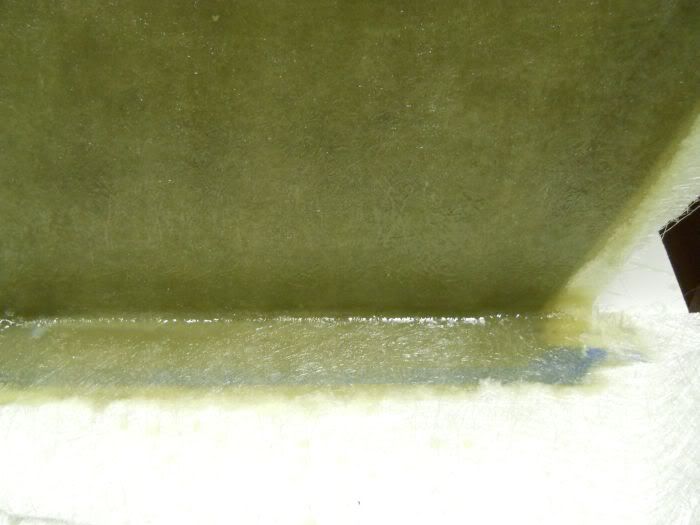

We got the curved skin out fairly quickly once the main bulk of the plug was removed.

It was just a case of the glue that bonded the plug together was not quite strong enough to take the loads that we were placing on it.

The next few pics show that even after taking the 'skin' out small bits still stayed in the mould.

Not too much of a bother but it would have been nice for it to come away as one.

If the plug had been a little more substantial then I feel that it would have come out without the cussing and the fight.

This is NOT a reflection of Mikes work by any means and nor is it a criticsm but merely an observation from a moulding point of veiw.

Offering up the nose sections of the mould you can see that it is going to be fun working that area when the time comes.

The mould has suffered a few little damaged areas and these will be dealt with simply after a full degrease and sand down.

The temperatures are set to come back up soon so progress will be quicker now over the coming days.

This will then be a good time to explain split lines and why they go where they go.

Cheers for now

P