Shes been built about 18 years, did it at my parents, with the help of my dad. Done i estimate conservatively 60,000 miles, used to use it every day to go to work up until recently. Been driven in anger a lot at York raceway, been to Belguim with classic ford, and has had 75 or 100 BHP of Trevors finest injected for about 6 years on the button, no progressive! all fitted and jetted by me.

Has been run wit zero oil pressure many times, due to sticking pressure relief valve, zero fuel pressure on 100bhp of gas due to me cocking up the fuel pumps, many 7000 rpm burnouts and line crosses, right up until my last visit at york!

so anyhow, i have just pulled a slug to check the oversize on the bigends, and thought id share howshe looks, im a gutted it isnt completely shot having lost allegedly 70bhp!! it used to make 220 at the wheels at my favourite rollers, which im told is impossible, all i know is i used the same guy, so if it went up or down i knew id made a difference!

All comments welcome, good or bad!

Heads off, very clean piston tops, zero DET, i just wiped the muck off one to see how much carbon was present, which was bugger all!

Bores have a very tiny bit of a wear lip, but its negligable, maybe a thou or 2!

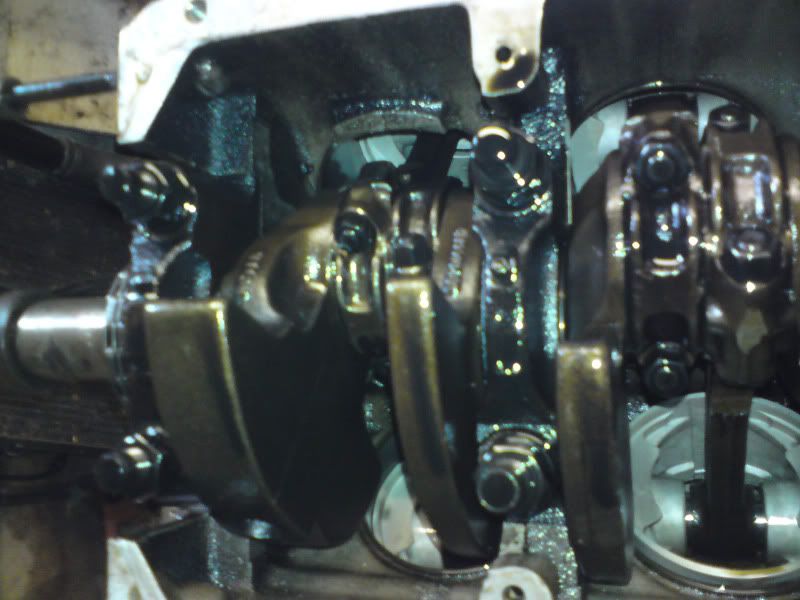

crank area, all the nice ARP studs and bolts mmmmm!

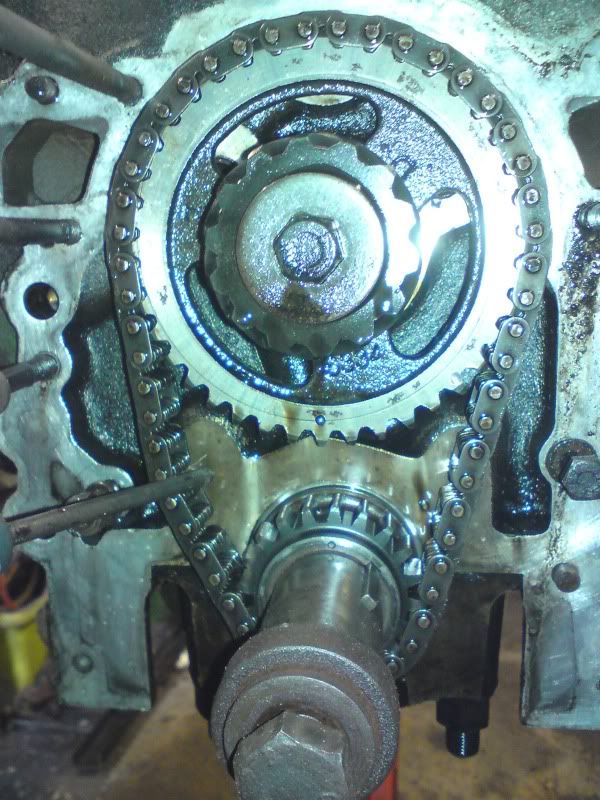

cam chain, metal gears, stretched but ive seen worse!

cam lobes, not as toasted as i was hoping! even the last 4 are nt showing any signs of major wear!

lifters(rhoads) all pretty normal stuff, now concave mind you!

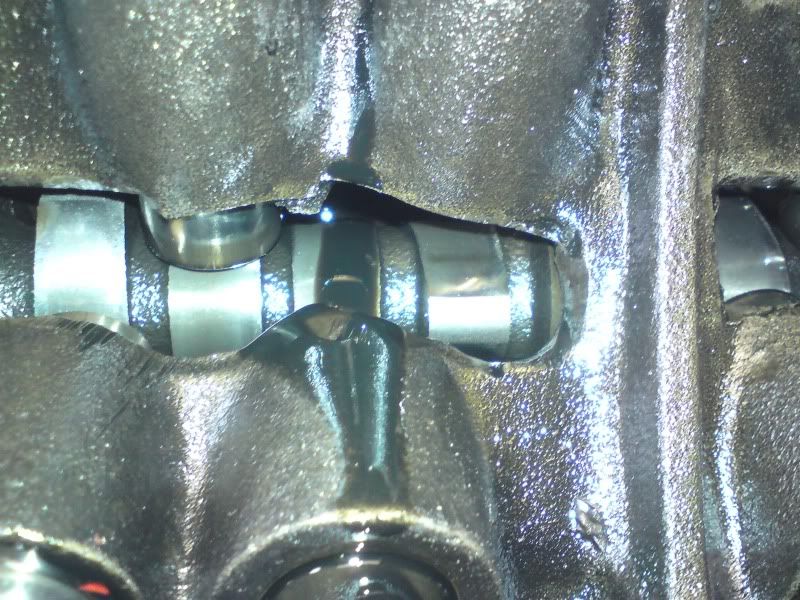

Crank, has a slight score wear some swarfe has picked out of the oil hole, but certainly wont need a grind if they are all this good!

Piston, sides wiped to inspect blow by, but topp as removed!

And the big ends, some wear but hey its not a new engine!! cap side

And top, certainly more wear, but better than expected to be fair, no scoring thank god apart from that mentioned earlier,

Must be an easier way to get to the starter motor!

So, all in no major wear, i have yet to inspect the valves ad guides, has it had a healthy oil habit, that certainly wasnt from the bores! so im expecting to have to change at least the guides, think i will use real steels phosphor bronze numbers to try and rteleive some of the side loading wear associated with cropped guides. My mate and i have summized that all the little bits of wear are sapping the power, mixed with the timing issues of the stretched chain etc, and im hoping for a new lease of life after the rebuild

one last point, what hydraulic lifters are people using, i have read that sd1 lifters rev to 6500rpm without float, is this true, as im not over keen on the rhoads as they amplify the camminessgiving very little below 3500rpm, but i need to hold the revs a bit to make full advantage of the cam (usually shift at 5500 - 6000 and i only have a 4 speed box so need this to cross the line as i run out of gears!)