poor piston to valve clearance cures

Moderator: phpBB2 - Administrators

poor piston to valve clearance cures

I have started to rebuild my rover 3500 engine have had the block machined flat as well as the heads machined flat heads are from a different engine but block and pistons are original my problem is that i have checked the hydaulic lifter preload and shimmed the rocker towers by 0.020" but when turning engine over by hand it locks up (belive that valve is hitting piston) by undoing rockers it turns over by hand fine.

my question is if the valve is hitting the piston how do i cure the problem i am using a tin gasket will going to composite give me enough clearance and can the tops of the pistons be machined if so what is the maximum amount its a 10;5 comp engine .

thanks

Davanda

my question is if the valve is hitting the piston how do i cure the problem i am using a tin gasket will going to composite give me enough clearance and can the tops of the pistons be machined if so what is the maximum amount its a 10;5 comp engine .

thanks

Davanda

Re: poor piston to valve clearance cures

I think you will have to experiment.

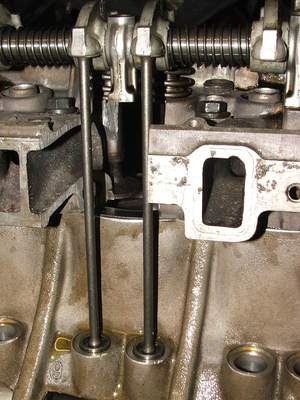

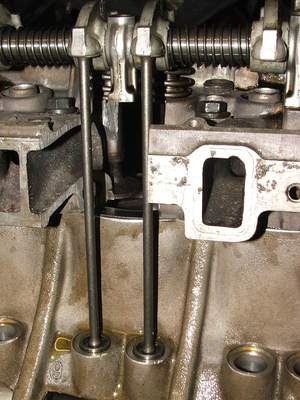

You could cut up a cylinder head like I did, then you can measure:

Or keep adding shims / an old composite gasket until it's clear. Then measure the gap with blue-tak.

0.020" shim is 0.5mm, so that's not a huge amount.

Chris.

You could cut up a cylinder head like I did, then you can measure:

Or keep adding shims / an old composite gasket until it's clear. Then measure the gap with blue-tak.

0.020" shim is 0.5mm, so that's not a huge amount.

Chris.

--

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Re: poor piston to valve clearance cures

Almost no cost really if you're the time and patience

Re: poor piston to valve clearance cures

Before you go carving your, possibly perfectly good, engine up it may be worth checking some basics.davnda wrote: ↑Fri Aug 26, 2022 9:19 amI have started to rebuild my rover 3500 engine have had the block machined flat as well as the heads machined flat heads are from a different engine but block and pistons are original my problem is that i have checked the hydaulic lifter preload and shimmed the rocker towers by 0.020" but when turning engine over by hand it locks up (belive that valve is hitting piston) by undoing rockers it turns over by hand fine.

my question is if the valve is hitting the piston how do i cure the problem i am using a tin gasket will going to composite give me enough clearance and can the tops of the pistons be machined if so what is the maximum amount its a 10;5 comp engine .

thanks

Davanda

Apart from the skim to the block and the heads, what other modfications are there from standard? I'm thinking specifically about the cam lift but other parts may have an influence (pistons, rods and so on)

Are you absolutely sure the cam timing is correct? The valves and piston will (probably) occupy the same space in the engine (interference engine) but if timing is correct this should not be at the same time.

Do you know how much material was removed from the heads and block? There is a measurement from the head face to the machined pads on top of the head which will allow you to check this (bearing in mind the heads may have been previously skimmed), can't remember what it is off hand but I think I found it on this site somewhere so a search would be useful. Composite gaskets are about 1mm thicker than the tin ones so if somewhere around this amount had been removed then using these will re-establish the head location in relation to crank centreline as well as getting the benefits of this gasket type.

What about mounting the heads on some spacers and seeing how much you need to lift them so that you don't get a problem? After checking the cam timing obviously.

Re: poor piston to valve clearance cures

First things first. What did you set preload to. Ideally you want 0.020 for best rpm potential. if you have more preload there is more chance of the valve hitting the piston when it is running in the event the lifters pump up. If you have had both head and block skimmed it is possible that you need a shorter pushrod to maintain geometry. You can raise the rocker posts a little but much more than 0.040" starts to be an issue, Normally you need less than that to make it right. What cam are you running, what is the lift, timing and lobe centre? I think as posted above it is quite likely the valve timing is incorrect.

Re: poor piston to valve clearance cures

thanks everyone for your suggestions so after reading the replies i double checked the cam timming agains the old cam and sproket and found about 90 degrees out took cam sproket off and found a timming mark on the other side (sprocket does not indicate front on it) the side that i had on the outside had a line cast onto 1 of the webs which i had mistaken for a timming mark (note to onself double check both sides in future) any way all looking good now

thanks for all your help im sure ill be back with more questions as the build progresses

thanks for all your help im sure ill be back with more questions as the build progresses

Re: poor piston to valve clearance cures

Good to hear it's all sorted. I always try and check the basics first as it's quite ofter where the problem is, probably easiest/cheapest to sort and need to be correct anyhow.davnda wrote: ↑Sat Aug 27, 2022 9:08 amthanks everyone for your suggestions so after reading the replies i double checked the cam timming agains the old cam and sproket and found about 90 degrees out took cam sproket off and found a timming mark on the other side (sprocket does not indicate front on it) the side that i had on the outside had a line cast onto 1 of the webs which i had mistaken for a timming mark (note to onself double check both sides in future) any way all looking good now

thanks for all your help im sure ill be back with more questions as the build progresses

I'd still look at swapping to composite gaskets if a significant amount has been removed from the block and head faces. If your engine already has 10.5:1 CR pistons not doing this will result in CR being too high (a concept I couldn't get over to the guys at RPi when I first got involved with this several year ago and hence had no further dealings with them).

I believe newer heads are already reduced in this area as they were made for being used with composite gaskets.

Apart from all that these gaskets will probably give a better seal.

Re: poor piston to valve clearance cures

But isn't more always better

Dax Rush 4.6 supercharged V8 MSII