Wiring from scratch, not so simple! Help!

Moderator: phpBB2 - Administrators

Wiring from scratch, not so simple! Help!

Having an absolute nightmare. The original plan for the skyline was to reuse the wiring loom that I pulled complete from the V8 S13 I removed the engine/ecu from. The skyline is for track only so I have spent the last week trying to remove parts of the loom that I won't be needing, lights, indicators, radio and other bits etc. The wiring loom was a right mess to start with.

The problem is, despite removing about half the loom, it's still massive and still looks an absolute mess! There's still parts in there I have no idea what they are from, plus I need to add further bits in. I think it will be easier for me to wire the car up from scratch!

Except I'm absolutely terrible with this sort of this, my head just melts. I've spent a week reading stuff on the internet and it just has made things worse. I can't find any single piece of useful information and I am getting very frustrated with it all. I got to this point with the MG and gave up, eventually breaking the car for parts about a year later (long story).

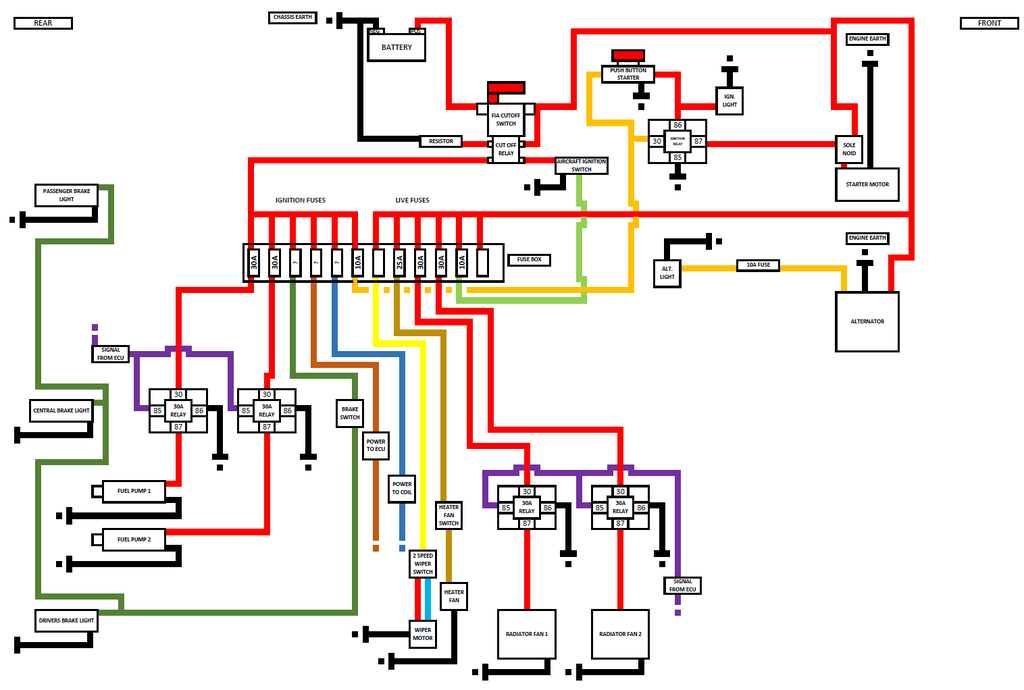

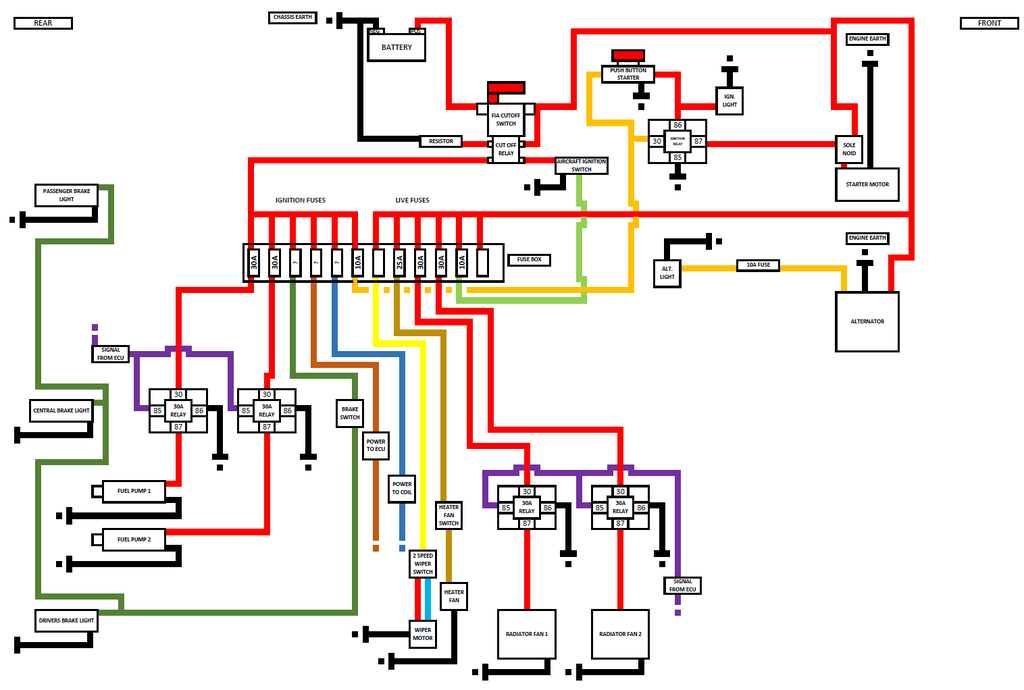

Can anyone help me out? I've drawn a very basic loom diagram but not even sure if it is correct. I'm wanting to run everything through relays.

Not sure how to attach files that aren't pics?

Apart from the normal engine loom (starter/alt etc) loom needs to have:

FIA kill switch

Push button starter/ignition toggle

2x fuel pump relays (ECU controlled)

2x fan relays (ECU controlled)

Small interior fan

2 speed wiper switch

Brake light switch/brake lights

Rev counter

Everything else is analogue or manual. I've not started looking at the ECU and associated bits of wiring yet

The problem is, despite removing about half the loom, it's still massive and still looks an absolute mess! There's still parts in there I have no idea what they are from, plus I need to add further bits in. I think it will be easier for me to wire the car up from scratch!

Except I'm absolutely terrible with this sort of this, my head just melts. I've spent a week reading stuff on the internet and it just has made things worse. I can't find any single piece of useful information and I am getting very frustrated with it all. I got to this point with the MG and gave up, eventually breaking the car for parts about a year later (long story).

Can anyone help me out? I've drawn a very basic loom diagram but not even sure if it is correct. I'm wanting to run everything through relays.

Not sure how to attach files that aren't pics?

Apart from the normal engine loom (starter/alt etc) loom needs to have:

FIA kill switch

Push button starter/ignition toggle

2x fuel pump relays (ECU controlled)

2x fan relays (ECU controlled)

Small interior fan

2 speed wiper switch

Brake light switch/brake lights

Rev counter

Everything else is analogue or manual. I've not started looking at the ECU and associated bits of wiring yet

RIP MGB V8 .... served me well as a learning curve.

R32 Skyline V8 .... this one is gonna be a monster!

R32 Skyline V8 .... this one is gonna be a monster!

It's a pretty major task even for someone who is well up on electrics.

A big problem is so many parts use a connector which may be just a maker's part and near impossible to source new.

I'd say it's going to be easier to use the original loom for the body and modify it as required. If it's in poor condition, I'd get a better one.

I'd also draw things out on your computer. Much easier to change a mistake there than in the flesh as it were. I'd happily check any diagrams you produce.

Do them as individual drawings. One for the lights. One for the ECU. Etc.

It takes time to draw them out - but well worth it in the end.

A big problem is so many parts use a connector which may be just a maker's part and near impossible to source new.

I'd say it's going to be easier to use the original loom for the body and modify it as required. If it's in poor condition, I'd get a better one.

I'd also draw things out on your computer. Much easier to change a mistake there than in the flesh as it were. I'd happily check any diagrams you produce.

Do them as individual drawings. One for the lights. One for the ECU. Etc.

It takes time to draw them out - but well worth it in the end.

Dave

London SW

Rover SD1 VDP EFI

MegaSquirt2 V3

EDIS8

Tech Edge 2Y

London SW

Rover SD1 VDP EFI

MegaSquirt2 V3

EDIS8

Tech Edge 2Y

I once helped a mate who didn't know much about electrics. He had a kit car which came with a loom and instructions, and even that proved a bit of a nightmare.

I recommend you find a friend who does understand how to wire up a car. If you do it yourself, it will just be a disaster.

Chris.

I recommend you find a friend who does understand how to wire up a car. If you do it yourself, it will just be a disaster.

Chris.

--

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

Series IIA 4.6 V8

R/R P38 4.6 V8

R/R L405 4.4 SDV8

Thanks for the quick reply guys. Unfortunately I don't know anyone who could help, I'm the only one of my mates into cars and building stuff like this!

Also spoke to a guy I know through another forum who builds bespoke looms, was quoted 800-1200 which is far more than I can afford.

I reckon I will give it a go myself then. I appreciate the offer of help/advice Dave and will probably take you up on that offer. And planning it bit by bit sounds like a good way to start.

I've already got plans for the dual pump wiring. The dual fans will be the same just need to find out the ecu fan control. I think i may be able to wire the wiper motor up using an MGB two speed switch. Brake switch/lights are simple.

I'll have a go at creating a diagram this wk and see how i get on with the engine loom.

Many thanks

Olly

Also spoke to a guy I know through another forum who builds bespoke looms, was quoted 800-1200 which is far more than I can afford.

I reckon I will give it a go myself then. I appreciate the offer of help/advice Dave and will probably take you up on that offer. And planning it bit by bit sounds like a good way to start.

I've already got plans for the dual pump wiring. The dual fans will be the same just need to find out the ecu fan control. I think i may be able to wire the wiper motor up using an MGB two speed switch. Brake switch/lights are simple.

I'll have a go at creating a diagram this wk and see how i get on with the engine loom.

Many thanks

Olly

RIP MGB V8 .... served me well as a learning curve.

R32 Skyline V8 .... this one is gonna be a monster!

R32 Skyline V8 .... this one is gonna be a monster!

I've made a full loom from scratch for my efi powered cobra. I used 8 relay bases with 3 fuses attached and worked from there. Then battery earth to chassis and positive to the starter motor ( kill switch in earth), starter motor to alternator, that's all the really heavy duty wiring done. I then took two feeds from the starter, one went direct to the fuses for unswitched live and the other went to the fuses through a heavy duty ignition switch. I then made up an individual drawing of every circuit needed and wired it AS a separate circuit from one of the fuses, this gave me 24 individual circuits which was more than enough for everything I needed including separate fuses for coils, injectors etc. I then wired each fuse up to either a switched positive or permanent as needed. hope that makes sense as it's not nearly as difficult as you'd think.

Big Tone

www.cobratone.co.uk

www.cobratone.co.uk

- Ian Anderson

- Forum Contributor

- Posts: 2396

- Joined: Sun Nov 19, 2006 9:46 pm

- Location: Edinburgh

You could try Isis

http://isispower.blogspot.co.uk

Or Painless

http://www.summitracing.com/int/search/ ... leSwitchNo

In the UK try vehicle wiring products

http://www.vehicle-wiring-products.eu

Ian

http://isispower.blogspot.co.uk

Or Painless

http://www.summitracing.com/int/search/ ... leSwitchNo

In the UK try vehicle wiring products

http://www.vehicle-wiring-products.eu

Ian

Owner of an "On the Road" GT40 Replica by DAX powered by 3.9Hotwre Efi, worked over by DJ Motors. EFi Working but still does some kangaroo at low revs (Damn the speed limits) In to paint shop 18/03/08.

Re: Wiring from scratch, not so simple! Help!

Olly, I've rewired a number of cars from scratch...most recently the MGB V8 [Griffith 4.0]. I always keep the the generic wiring and function control separate from the ECU/injection-side and approach as two separate applications. If this was me I'd wire up the generic car functions first...excluding the ECU & injection, then complete the ECU and injection as this enables separate testing post install and really eases any post-install fault finding. Start off with a central fuse & relay board that has capacity for all the required circuits plus a couple extra, install and run the colour coded wiring to each application. One other big advantage here is that you can strip out all the unecessary weight of the existing looms :. keeping weight to the minimum. The only other note is that wiring a car is a pain in the arse to do properly...but it's really worth it. Good luck...chodjinn wrote:Apart from the normal engine loom (starter/alt etc) loom needs to have:

FIA kill switch

Push button starter/ignition toggle

2x fuel pump relays (ECU controlled)

2x fan relays (ECU controlled)

Small interior fan

2 speed wiper switch

Brake light switch/brake lights

Rev counter

Everything else is analogue or manual. I've not started looking at the ECU and associated bits of wiring yet

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

If you can buy a harness kit, it will make life a lot easier.

UK source, no idea what it contains

http://www.s-v-c.co.uk/product/front-en ... ular-loom/

http://www.rapidfitlooms.co.uk/trade.htm

http://www.carbuildersolutions.com/uk/c ... ing-module

US

http://spaghettimenders.com/motoronly.html

There are lots of universal options in the US and they're usually quite comprehensive. But choose wisely or you'll need to make loads of changes anyway

But they can make life a lot easier.

http://www.summitracing.com/int/search/ ... cation=int

Car functions may be minimal, but it can be worth keeping the engine loom totally separate from the chassis loom, even if some items do overlap like fans etc

Some of the universal US loom/fuse/relay kits tend to switch the relays via 12v switches so for ecu controlled stuff you'd need to do some adjustments there.

UK source, no idea what it contains

http://www.s-v-c.co.uk/product/front-en ... ular-loom/

http://www.rapidfitlooms.co.uk/trade.htm

http://www.carbuildersolutions.com/uk/c ... ing-module

US

http://spaghettimenders.com/motoronly.html

There are lots of universal options in the US and they're usually quite comprehensive. But choose wisely or you'll need to make loads of changes anyway

But they can make life a lot easier.

http://www.summitracing.com/int/search/ ... cation=int

Car functions may be minimal, but it can be worth keeping the engine loom totally separate from the chassis loom, even if some items do overlap like fans etc

Some of the universal US loom/fuse/relay kits tend to switch the relays via 12v switches so for ecu controlled stuff you'd need to do some adjustments there.

Making up a new loom from scratch is going to be expensive. Materials cost - as does the labour. That's why it's generally better to modify an existing loom - assuming it is in decent condition.

I've made a fair few RV8 engines looms for MegaSquirt and generally use a hotwire one as a basis. But the connectors needed for that are common and even just the terminals are available. Many car looms these days use maker specific connectors - but I dunno if the Skyline does.

Sadly, the ability to create a decent wiring loom needs basic skills as regards electrics many may not have. And it's not something you can learn up about quickly. In much the same as you couldn't quickly teach how to rebuild an engine to someone who had never wielded a spanner.

I've made a fair few RV8 engines looms for MegaSquirt and generally use a hotwire one as a basis. But the connectors needed for that are common and even just the terminals are available. Many car looms these days use maker specific connectors - but I dunno if the Skyline does.

Sadly, the ability to create a decent wiring loom needs basic skills as regards electrics many may not have. And it's not something you can learn up about quickly. In much the same as you couldn't quickly teach how to rebuild an engine to someone who had never wielded a spanner.

Dave

London SW

Rover SD1 VDP EFI

MegaSquirt2 V3

EDIS8

Tech Edge 2Y

London SW

Rover SD1 VDP EFI

MegaSquirt2 V3

EDIS8

Tech Edge 2Y

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

If you can put the factory loom back in.....do it lol

I've never figured out why people torture themselves like that. Something that was in and working perfectly....they decide to rip it out and give themselves a headache and cost a fortune.

I can understand for those going all out with weight reduction and they've plenty of money to spend to make a new loom.

But for most, it's just more hassle than it's worth.

Wiring can be a pain in the hole....even more so if you have no wiring, tools, parts, connectors etc etc. Don't underestimate the work involved, and it will cost a lot more than you think.

Buying a pre-made or half made loom will make so much sense even if you think it's more expensive initially.

I've never figured out why people torture themselves like that. Something that was in and working perfectly....they decide to rip it out and give themselves a headache and cost a fortune.

I can understand for those going all out with weight reduction and they've plenty of money to spend to make a new loom.

But for most, it's just more hassle than it's worth.

Wiring can be a pain in the hole....even more so if you have no wiring, tools, parts, connectors etc etc. Don't underestimate the work involved, and it will cost a lot more than you think.

Buying a pre-made or half made loom will make so much sense even if you think it's more expensive initially.

Ok this is what I knocked up this morning. I'm not sure on the starter button/ignition toggle/ignition relay etc. at the moment ... or most of it!

Also not sure on fuses. I know I should use a 30A relay for the fuel pumps, but what about fuse size? Etc!

Also not sure on fuses. I know I should use a 30A relay for the fuel pumps, but what about fuse size? Etc!

RIP MGB V8 .... served me well as a learning curve.

R32 Skyline V8 .... this one is gonna be a monster!

R32 Skyline V8 .... this one is gonna be a monster!

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Fuse size depends on the load of the items on that circuit. Get it all working and measure the loads then determine safest fuse size.

IMO for a single fuel pump, 30A is quite a lot, but it does depend on the fuel pump you're using and the work you're expecting it to do.

My 044's run around 11-12A each with a max of around 13-14A at say 80psi

Some pumps will use more, some less.

I personally dont like separate fuses and relays for a dual pump installation.

if one fuse or relay fails...it could leave you short on fuel supply. So unless your ecu etc has failsafes to watch over this it could result in a busted engine.

If both pumps are wired off a single fuse and relay, if either blows, the engine stops.

Probably a rare scenario, but possible.

I think Devonman is correct about the alternator too....with the only caveat being make sure it is a typical 1 wire alternator in the first place. Not all are, especially modern stuff.

When the alternator starts charging then there is 12v to both sides of the lamp and it shuts off, with alternator stationary the light would be on.

Not sure on the purpose or specifics of the cut-off relay, but ensure the alternator does isolate from all electrical loads when the cut off is active otherwise it will continue to power everything if the engine is still running.

IMO for a single fuel pump, 30A is quite a lot, but it does depend on the fuel pump you're using and the work you're expecting it to do.

My 044's run around 11-12A each with a max of around 13-14A at say 80psi

Some pumps will use more, some less.

I personally dont like separate fuses and relays for a dual pump installation.

if one fuse or relay fails...it could leave you short on fuel supply. So unless your ecu etc has failsafes to watch over this it could result in a busted engine.

If both pumps are wired off a single fuse and relay, if either blows, the engine stops.

Probably a rare scenario, but possible.

I think Devonman is correct about the alternator too....with the only caveat being make sure it is a typical 1 wire alternator in the first place. Not all are, especially modern stuff.

When the alternator starts charging then there is 12v to both sides of the lamp and it shuts off, with alternator stationary the light would be on.

Not sure on the purpose or specifics of the cut-off relay, but ensure the alternator does isolate from all electrical loads when the cut off is active otherwise it will continue to power everything if the engine is still running.

Interesting Stevie, from what I have read the dual fuel pump relays is to ensure that both pumps get a decent amp feed. But then again you have direct experience! And I wouldn't be running anywhere near the power you are. Pumps are a basic HP electric lift pump and a Sytec HP pump. I may change it to one relay then.

The FIA kill switch comes with the relay attached, you have to use them for racing to ensure total kill of engine.

I've already got the FIA kill switch, push button start/relay and a bunch of other stuff left over from my MGB project so will be using those (all new).

And you're right, the alternator is a 3/4 wire. Will have a rethink.

I'm pretty happy on the individual circuits for the moment, it's getting the ignition/battery/alternator all wired up I'm still not sure on

The FIA kill switch comes with the relay attached, you have to use them for racing to ensure total kill of engine.

I've already got the FIA kill switch, push button start/relay and a bunch of other stuff left over from my MGB project so will be using those (all new).

And you're right, the alternator is a 3/4 wire. Will have a rethink.

I'm pretty happy on the individual circuits for the moment, it's getting the ignition/battery/alternator all wired up I'm still not sure on

RIP MGB V8 .... served me well as a learning curve.

R32 Skyline V8 .... this one is gonna be a monster!

R32 Skyline V8 .... this one is gonna be a monster!