Jag IRS mods!!!!!!!!

Moderator: phpBB2 - Administrators

Jag IRS mods!!!!!!!!

Hi guys I need some help I am looking at using a jag irs rear axle setup , but the problem lies with the wheel pcd on the jag is different to what I want to use as ,I have some very differant wheels that cost a lot of money and i don't want to change them so the question is does any body no how or were I could get drive flanges that have a pcd of 6 x 139.7 for my wheels to fit an jag irs axle? I have found some one that has done it on a toyota pickup but i can't find any details on how he did it any help would be great.

- russell_ram

- Getting There

- Posts: 238

- Joined: Mon Nov 20, 2006 1:03 pm

- Location: Midlands

I have never seen after market hubs/flanges for a jag axle. You could, of course, have some machined up yourself - which I have seen - to suit stud drive wheels/centre nut.

Alternatively, what's wrong with getting your existing ones re-drilled to suit your wheel PCD?

Russ

Alternatively, what's wrong with getting your existing ones re-drilled to suit your wheel PCD?

Russ

Rover Powered to 11.63sec @ 128mph.

-

CastleMGBV8

- Top Dog

- Posts: 2334

- Joined: Sat Aug 18, 2007 5:09 pm

- Location: Sidcup, Kent, UK

Re: Jag IRS mods!!!!!!!!

Just coverted your metric size and that give a 5.5" PCD and the Jag is I believe 5 x 4.75" the main problem is you are using six stud wheels and you will probably find that at leest one of the new studs will clash with one of the original stud holes.L350MD wrote:Hi guys I need some help I am looking at using a jag irs rear axle setup , but the problem lies with the wheel pcd on the jag is different to what I want to use as ,I have some very differant wheels that cost a lot of money and i don't want to change them so the question is does any body no how or were I could get drive flanges that have a pcd of 6 x 139.7 for my wheels to fit an jag irs axle? I have found some one that has done it on a toyota pickup but i can't find any details on how he did it any help would be great.

Try a mock up with a piece of card with your PCD and see how it works on the hub face.

If it will work and with the larger PCD leaving enough metal outside the ring of studs, then take the hubs to a decent engineering shop and have the re-drilled for the studs that match your wheels.

Whats the vehicle. as 6 studs tend to be commercial or some thing heavy?

Kevin.

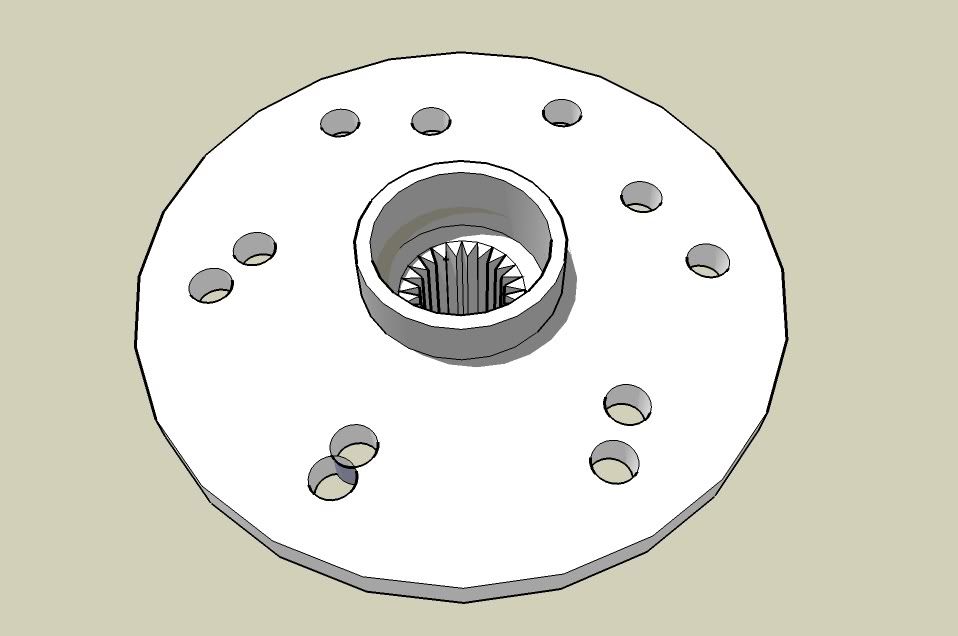

Hi guys Thanks foe the replys russ the problem i have with re drilling it is like kevin said that the holes would over lap in one place i have tryed it out with google sketchup modling it up and moving one set of holes but you always end up with one hole over lapping see pic below.

[/img]

[/img]

This is also if there is that much diameter on the origanal drive flanges to even put the lager pcd i can't check as i don't have an axle yet.

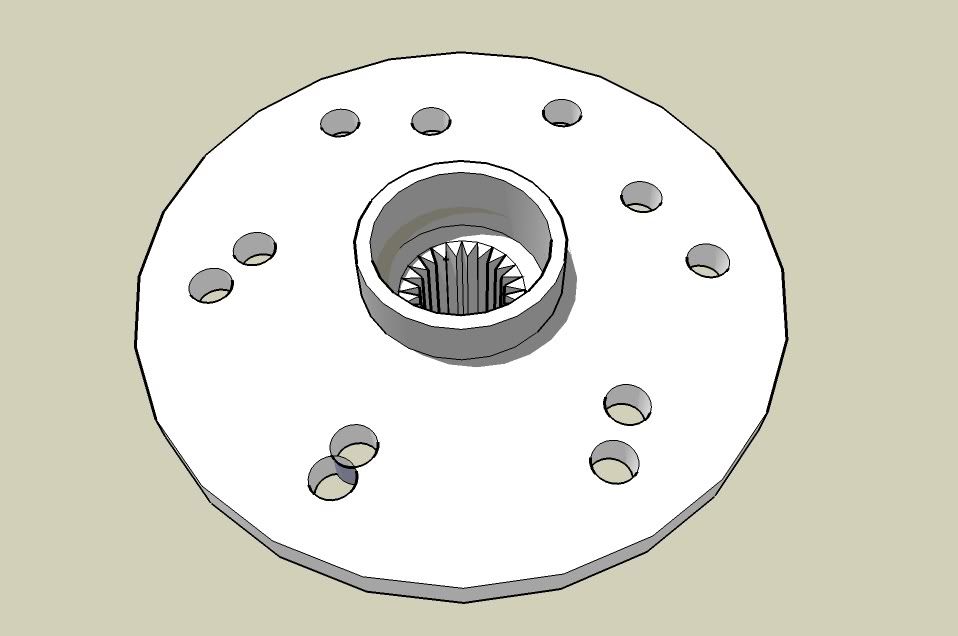

Below is a picture of the ones on the guys hilux pickup that i found which has te same pcd as i need they look like a custom part.

And kevin you asked what the vehilce is it was a jap mitsubishi 4wd that is being made 2wd with a rover v8 3.9 engine and lowered.

[/img]

[/img]This is also if there is that much diameter on the origanal drive flanges to even put the lager pcd i can't check as i don't have an axle yet.

Below is a picture of the ones on the guys hilux pickup that i found which has te same pcd as i need they look like a custom part.

And kevin you asked what the vehilce is it was a jap mitsubishi 4wd that is being made 2wd with a rover v8 3.9 engine and lowered.

-

CastleMGBV8

- Top Dog

- Posts: 2334

- Joined: Sat Aug 18, 2007 5:09 pm

- Location: Sidcup, Kent, UK

The hub/upright in the pictiure is I suspect from one of the american companys that specialise in upgrading jag rear end and will have the hub face drilled for the required PCD and not cheap especially at the moment with our current exchange rate.

A simple way to do it would be to weld up the hole which is goint to be an interferance and then have the new stud holes drilled, should be perfectly safe bearing in mind that you will have six studs.

A good UK source of Jag conversion parts is Pop Browns 08456 588 191

The pictured hub may come from http://www.cwiinc.com or Kugel Components at http://www.kugelkomponents.com

and another useful uk supplier http://www.jagaxles.com

Kevin

A simple way to do it would be to weld up the hole which is goint to be an interferance and then have the new stud holes drilled, should be perfectly safe bearing in mind that you will have six studs.

A good UK source of Jag conversion parts is Pop Browns 08456 588 191

The pictured hub may come from http://www.cwiinc.com or Kugel Components at http://www.kugelkomponents.com

and another useful uk supplier http://www.jagaxles.com

Kevin

I'd drill and tap the hole you want plugging, put a 1/8" weld prep chamfer, make a plug to screw in, then carefully tig or arc weld round it. Too much heat and you can distort the flange.

Don't mig weld it either, as it'll likely be too hard you'll never be able to drill it out for the new hole.

Got the T shirt.

Don't mig weld it either, as it'll likely be too hard you'll never be able to drill it out for the new hole.

Got the T shirt.

-

koopsterman

- Forum Contributor

- Posts: 55

- Joined: Sun Nov 07, 2010 9:27 pm

- Location: Basildon Essex

I can confirm the drilling and tapping/welding idea works as I have done it myself on a couple of Volvo 240 axles which have a pcd which did not suit the wheels I wanted to fit, due to the length of the half-shafts I put them in a dividing head and carried out the hole spacing in a horizontal plane rather than the normal vertical plane, worked a treat.

How critical is the offset? can you not turn the existing hub down to the inside of the existing stud holes, make up a new flange and put the new wheel studs in that at the desired PCD. Put a thread on that shoulder in the centre o the hub and one to match on the hole in the middle of the mounting flange and put 6 holes through both the hub and the flange you have made to take short counter sunk bolts to hold them together and stop them turning, you will obviously need left hand thread on one side and right on the other but done neatly you should only change the off set by the thickness of the adaptor flange, say 3/8 of an inch either side. If there is enough room at the wheel centres you could reduce this by counter boring the back face to recess the hub into the adaptor and machining the outsice wheel mounting face back to reduce the off set.

Best regards

Mike

Best regards

Mike

poppet valves rule!