Sorry everyone,

I sorta left this thread hanging there. It's been a while since i've been on this forum. I actually manufactured the mixer ring and installed it. I'm just copying and pasting part of the thread here, June 2008:

I took off the old mixer ring from my intake manifold

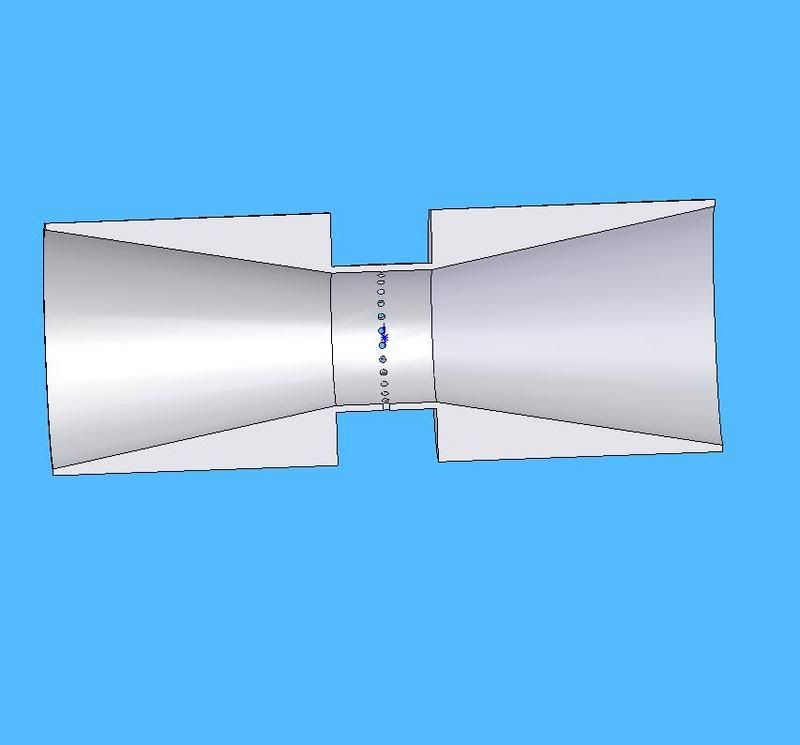

Here is the comparison of the old mixer ring with the new one which I designed:

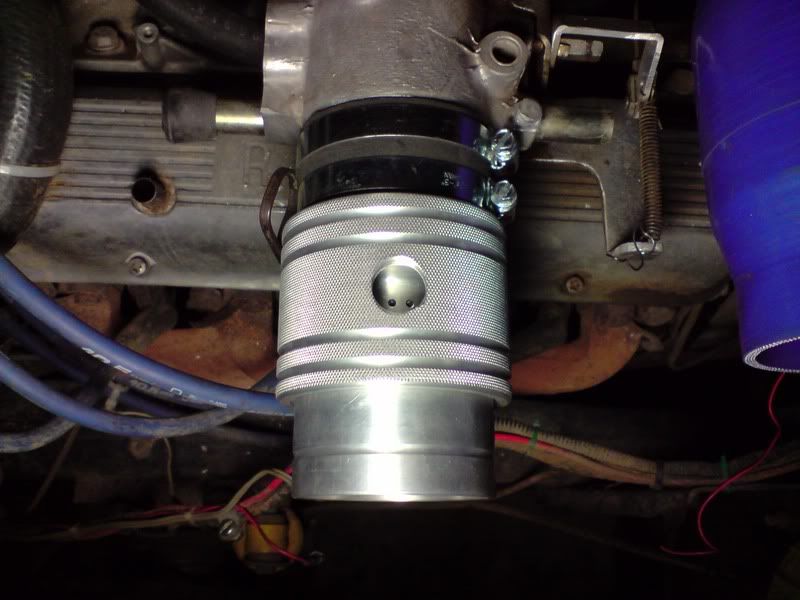

And I then started fitting the new mixer ring onto the engine.

The core of the mixer:

O-rings

The collar, this was so hard to get on with 4 O rings!:

And finally the brass fitting for the gas feed:

Flexible 3" pipe to join it all together:

The mixer ring was a partial success, the engine did respond much better with this ring, however it isn't perfect. At full throttle openings you don't get the mixing effect of the butterfly and the lpg doesn't mix with the air properly, and since I was using an EFI manifold with trumpets in the plenum I suspect that at WOT the air fuel ratio varied across cylinders. It was actually not that noticeable but i'm pretty sure that this design isn't ideal at WOT.

The engine was perfectly drivable though and I have been using it for the last 10 or so months without issue... until I broke my transfer case a couple of months ago, but that is a different story.

I've started a new project car and I'm thinking of doing a twin turbo 3.9L engine on LPG as well... This style of mixer will work just fine on a suck through setup because the compressor on the turbo will ensure that the air and fuel always mixes, no matter what the position of the throttle body is.... anyway, that is all a long way off yet, I gotta finish building up the rear wall on the car (I cut a discovery in half!).