Page 1 of 2

Electric waterpumps - pressure important?

Posted: Mon Sep 12, 2011 1:10 pm

by SuperV8

Due to supercharger belts 'challenges' i've been looking at using an electric water pump. The Davies Craig ones have caught my eye, quoting 35 g/min flow.

My concern is none of the electric water pumps i've looked at mentions any pressure figures! When I brought my new fuel pump it was always a certain flow at a certain pressure!

Reading the book - Forced Induction Performance Tuning: Bk. H691 by A.Graham Bell enforced my concern my mentioning the important part about coolant pumps is working at a pressure of 30-40psi in the block so the areas arround the valves cannot boil.

Should I be looking for a pump that can flow 35 g/min @ 30-40psi? I'm aiming for 400hp from my supercharged 4.6 so it is not a standard engine.

Any thoughts or comments welcome,

Tom.

Posted: Mon Sep 12, 2011 5:59 pm

by Ian Anderson

Hi I am not sure re your pressure. Yes it has to be able to cope with the 14 to 25 psi of the water systems as it pressurises to the level on your overflow pressure cap.

But remember you still need to make the electricity by driving the alternator sp perhaps not to muvh difference - other than not spooking your water pump to 6000 rpm in each gear

Ian

Posted: Mon Sep 12, 2011 9:54 pm

by kev_the_mole

Hi,

I think any of them will do the job as long as the flow is high enough. I went to electric as the Chevy would boil at tickover after about 4 minutes and I wanted to be sure that I had enough flow and that wasn't causing the problem (it wasn't

). I discounted Davies Craig as they seemed a bit lightweight and 'plasticky and went for a bolt-on Proform for the SBC.

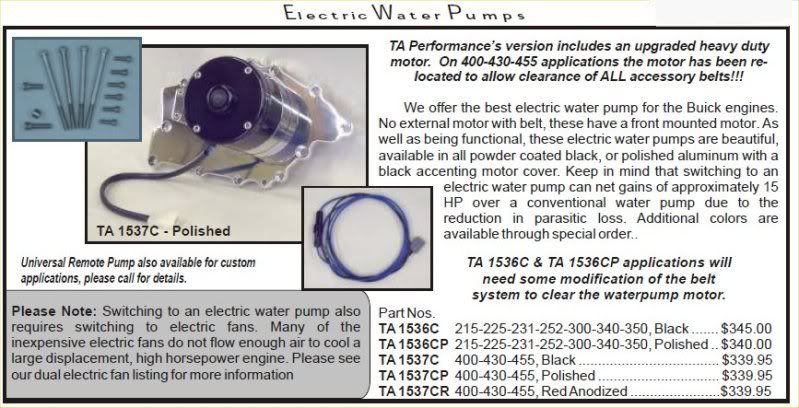

The only bolt-on I've found for the Rover/Buick is from TA Performance as below

Not being sure of the longevity of the Proform I also invested in a heavy duty 60gpm Jegs system that still sits in the garage

along with a secondhand Davies Craig

Posted: Tue Sep 13, 2011 9:22 am

by kiwicar

Hi

The cooling pump funtions in a closed system, the pressure on the inlet side and outlet side is virtually the same, strictly speaking it is operating as an impeller not a classic pump, it never develops a head of pressure, what pressure there is is due to heating of the coolent. Operating pressuer therefoe does not effect flow.

A fuel pump however operates to develop a raised pressure in a system with the pressure across it's input and output so flow at a given pressure is relevent.

Hope that makes sence

Best regards

Mike

Posted: Tue Sep 13, 2011 3:15 pm

by SuperV8

Hi Mike,

Thanks yes makes sense.

Was just reading the book on tuning: Forced Induction Performance Tuning: Bk. H691 by A.Graham Bell he mentions in the section about water pumps that it is important to use the correct size restrictor in place of a thermostat in order to maintain 30 - 40psi in the engine to pack against the back of the valves to stop local over heating and boiling? Not sure if he means total of 30-40psi so 15psi rad cap pressure plus 15psi pump pressure? Maybe i'm just getting a little confused (not the first time!

)

I have since found the spec sheet for the davies craig ewp115 and they do show a pressure/flow graph which. It's interesting they call it the 115 L/m flow but also on a vidio they have done they call it 35g/m flow! From their flow graph 35 g/m is peak flow at 0 pressure and 115 L/m is at 0.2 bar! Why would they use two different parameters? This was concern when trying to pick a pump knowing the marketing BS that goes on is the flow that any of the water pumps are quoted at peak/free flow to a bucket? or at a pressure?

Kev,

which davies craig pump do you have in the garage the 80 or the 115? I may be interrested in the CD115 or the Jegs if I can find space if they are for sale?

Tom.

Posted: Tue Sep 13, 2011 3:21 pm

by kiwicar

Was just reading the book on tuning: Forced Induction Performance Tuning: Bk. H691 by A.Graham Bell he mentions in the section about water pumps that it is important to use the correct size restrictor in place of a thermostat in order to maintain 30 - 40psi in the engine to pack against the back of the valves to stop local over heating and boiling? Not sure if he means total of 30-40psi so 15psi rad cap pressure plus 15psi pump pressure? Maybe i'm just getting a little confused (not the first time! )

Hi

that makes no sence to me, can't see how a restrictor in the thermostat would effect the pressure in the heads esppecially the "back of the valves" which as far as I remember are in the exhaust ports???

Best regards

Mike

Posted: Tue Sep 13, 2011 6:25 pm

by sidecar

The restrictor would be in the outlet of the heads which then creates the pressure because the pump is forcing coolant into them. A thermostat also performs this function even when it is open. The rad cap does not 'see' this pressure which is why it can be set to 15 PSI and still not blow off.

The reason that he talks about using a restrictor rather than a thermostat is because he is talking about pure race engines, racers do not like the idea of a thermostat because if it sticks closed they will cook the motor. The temp is controlled by blocking off some of the rad with tape.

The pressure 'packs' the coolant into the heads which helps to stop hot spotting and thus steam pockets forming.

I got the above gumph from A G Bells book on 4 stroke tuning!

Posted: Tue Sep 13, 2011 9:02 pm

by kev_the_mole

Tom,

You have a PM.

Ian

Posted: Thu Sep 15, 2011 11:36 am

by stevieturbo

Some people do use the Davies Craig pump with success. I owned one many years ago, and ended up giving it away. I personally thought it was crap. Expensive plastic crap at that.

But again...some people including race teams do use them with success.

Stewart Components make much nicer pumps, with far more ability. I even seen that Prodrive fit them to some of the LeMans racers they build.

Posted: Fri Oct 14, 2011 1:53 pm

by jefferybond

sidecar wrote:The restrictor would be in the outlet of the heads which then creates the pressure because the pump is forcing coolant into them. A thermostat also performs this function even when it is open. The rad cap does not 'see' this pressure which is why it can be set to 15 PSI and still not blow off.

The reason that he talks about using a restrictor rather than a thermostat is because he is talking about pure race engines, racers do not like the idea of a thermostat because if it sticks closed they will cook the motor. The temp is controlled by blocking off some of the rad with tape.

The pressure 'packs' the coolant into the heads which helps to stop hot spotting and thus steam pockets forming.

I got the above gumph from A G Bells book on 4 stroke tuning!

That sounds like rubbish to me. Just imagine the flow rate you'd need through a restrictor to get 30 psi pressure difference! A standard 15psi rad cap will allow the water to get to about 122deg before boiling anyway.

Also, remember that even when the thermostat is completely shut, there will still be water circulation via the bypass port.

Posted: Fri Oct 14, 2011 6:55 pm

by DEVONMAN

A G Bell is not just talking about the RV8 cooling system.

Although the cooling system is a closed system by virtue of the radiator pressure control cap, there are still differences in pressure due to restrictions. When a restriction is introduced the pressure in front of the restriction is greater than after it and this is possible due to rubber hoses in the system. The hoses are normally expanded by the normal system pressure but will shrink when the pump is working against a restrictor and the pressure between the pump and the restrictor will be increased.

If you consider a blocked radiator as a kind of restrictor, the bottom hose tends to collapse if the pump speed is raised above a certain point and the top hose expands. This demonstrates a difference in pressure across the pump.

I believe A G Bell is talking about controlling local boiling due to local surface temperatures far above the boiling point at the normal system pressure, these temperatures being due to direct conduction across the casting near exhaust valves etc. This effect can be seen in an electric kettle where bubbles form on the hot element surface well before the water gets anwhere near boiling point. If the kettle was pressurised then these bubbles would be surpressed untill a higher temperature.

cheers Denis

Posted: Fri Oct 14, 2011 7:59 pm

by jefferybond

DEVONMAN wrote:A G Bell is not just talking about the RV8 cooling system.

Although the cooling system is a closed system by virtue of the radiator pressure control cap, there are still differences in pressure due to restrictions. When a restriction is introduced the pressure in front of the restriction is greater than after it and this is possible due to rubber hoses in the system. The hoses are normally expanded by the normal system pressure but will shrink when the pump is working against a restrictor and the pressure between the pump and the restrictor will be increased.

If you consider a blocked radiator as a kind of restrictor, t7he bottom hose tends to collapse if the pump speed is raised above a certain point and the top hose expands. This demonstrates a difference in pressure across the pump.

I believe A G Bell is talking about controlling local boiling due to local surface temperatures far above the boiling point at the normal system pressure, these temperatures being due to direct conduction across the casting near exhaust valves etc. This effect can be seen in an electric kettle where bubbles form on the hot element surface well before the water gets anwhere near boiling point. If the kettle was pressurised then these bubbles would be surpressed untill a higher temperature.

cheers Denis

Yes I agree with all of the above, and of course any restriction will have a pressure drop across it. However, I can believe any pressure difference will be more than a couple of psi at the most - certainly insignificant compared to the 15-odd Psi of static pressure.

A previous post mentioned 30psi drop across a restriction! That would be some amazing water pump.

Posted: Sat Oct 15, 2011 5:00 am

by unstable load

A previous post mentioned 30psi drop across a restriction! That would be some amazing water pump.

Indeed, that equates to a 70 FOOT head of water and is heading towards small borehole capacity....

Posted: Sat Oct 15, 2011 8:45 am

by DEVONMAN

unstable load wrote:A previous post mentioned 30psi drop across a restriction! That would be some amazing water pump.

Indeed, that equates to a 70 FOOT head of water and is heading towards small borehole capacity....

I think the general idea of a restrictor or thermostat in the outlet from the heads is sound and helps delay pump cavitation and local boiling at hot spots.

I assume the 30psi pressure stated by A G Bell is rad cap pressure (15psi) plus 15psi pump induced pressure.

This additional 15 psi might just be achievable at a pump speed of 5000-6000 revs but that seems optimistic and without a test I'll give A G wells the benefit of the doubt.

The question is, If I disconnect the heater inlet hose at 5000 rpm, will the water shoot 34 feet in the air ?? . Anyone want to try it

Cheers Denis

Posted: Sat Oct 15, 2011 9:04 am

by sidecar

jefferybond wrote:sidecar wrote:The restrictor would be in the outlet of the heads which then creates the pressure because the pump is forcing coolant into them. A thermostat also performs this function even when it is open. The rad cap does not 'see' this pressure which is why it can be set to 15 PSI and still not blow off.

The reason that he talks about using a restrictor rather than a thermostat is because he is talking about pure race engines, racers do not like the idea of a thermostat because if it sticks closed they will cook the motor. The temp is controlled by blocking off some of the rad with tape.

The pressure 'packs' the coolant into the heads which helps to stop hot spotting and thus steam pockets forming.

I got the above gumph from A G Bells book on 4 stroke tuning!

That sounds like rubbish to me. Just imagine the flow rate you'd need through a restrictor to get 30 psi pressure difference! A standard 15psi rad cap will allow the water to get to about 122deg before boiling anyway.

Also, remember that even when the thermostat is completely shut, there will still be water circulation via the bypass port.

Pressure is independentof flow rate, you can can pressure with no flow at all. On the other hand you can not have flow without pressure.

This could all be tested by having a pressure gauge tapped into the cooling system engine side of the thermostat. A G Bell builds engine for a living (and writes books), I suspect that he has tried this sort of stuff on a dyno. (Of course I can not be sure).