Page 1 of 3

3.9 rebuild ready for blower questions here we go again :)

Posted: Sat Sep 04, 2010 9:58 pm

by stagcar

Hi every one

Just sold the old landy 101 block so starting the 3.9 build

Sorry for the questions but here we go...

1) cr of the engine is 9 35 should i lower it using comosit gasket? i want to run about 6-8 psi of boost with no charge cooler.

2)The engine has covered about 120.000 miles so its going to get a rebuild with arp studs and new shells but should i bother with rings and bores? or not mess with it? compresion check was good.

3) am i ok to run the SD1 timing case and pump on this engine?

Sorry for all the questions

Thanks again

Derek

Posted: Sat Sep 04, 2010 11:50 pm

by topcatcustom

CR should be ok but if you lower it then wont make massive differnce and wont have to worry about lower octane fuel, I'd be tempted to do the rings and a hone anyway, and check and probably replace the cam bearings. SD1 cover should be fine if not worn out. check all ring gaps as if standard out of the box rings they will probably all be different.

Posted: Sun Sep 05, 2010 7:53 am

by kiwicar

As Tom says a light hone re-ring and gap the rings (to standard) I wouldn't lower the CR, if you do want to use comp gaskets skim the block a little but keep the CR above 9.25:1you want to keep the squish band tight. I would pull the oil gallery plugs and thoroughly clean the galleries especially on an engine that has done 120K miles.

Best regards

Mike

Posted: Sun Sep 05, 2010 8:07 am

by stagcar

Thanks guys

I will stick with the tin head set then.

Looking at the state of the engine it a wonder it ran so well the cam chain is stretched to hell i recon its got a good 1.5 inch slack on it.

Havent got the cam out yet but it must be only good for scrap after 120k

what are the cam berings like to do? they look a bit of a mare to me

Thanks again

Derek

Posted: Sun Sep 05, 2010 9:20 am

by ChrisJC

Doing cam bearings is easy, but you do need the special tools to do it. If you have access to a lathe or a friendly turner:

http://www.cowdery.org.uk/downloads/V8-Cam-brg-tool.pdf

Note that you need the parts drilled and tapped for a long piece of studding so you can draw the bearings out.

Chris.

Posted: Sun Sep 05, 2010 10:36 am

by stagcar

ChrisJC wrote:Doing cam bearings is easy, but you do need the special tools to do it. If you have access to a lathe or a friendly turner:

http://www.cowdery.org.uk/downloads/V8-Cam-brg-tool.pdf

Note that you need the parts drilled and tapped for a long piece of studding so you can draw the bearings out.

Chris.

Thanks for that Chris

Actualy dosent look that bad then after the bits have been made up

I will check my ones out first and if there ok will leve them b but if not i will get my inlaw to knock them up for me. he loves a bit of turning so i am told

Thanks again

Derek

Help this thing is very ill

Posted: Sun Sep 05, 2010 10:26 pm

by stagcar

Hi All

It looks like bad news to me. just poped the heads of the 3.9 that i will say now was running up the scrappy and sounded sweet and was burning no oil!

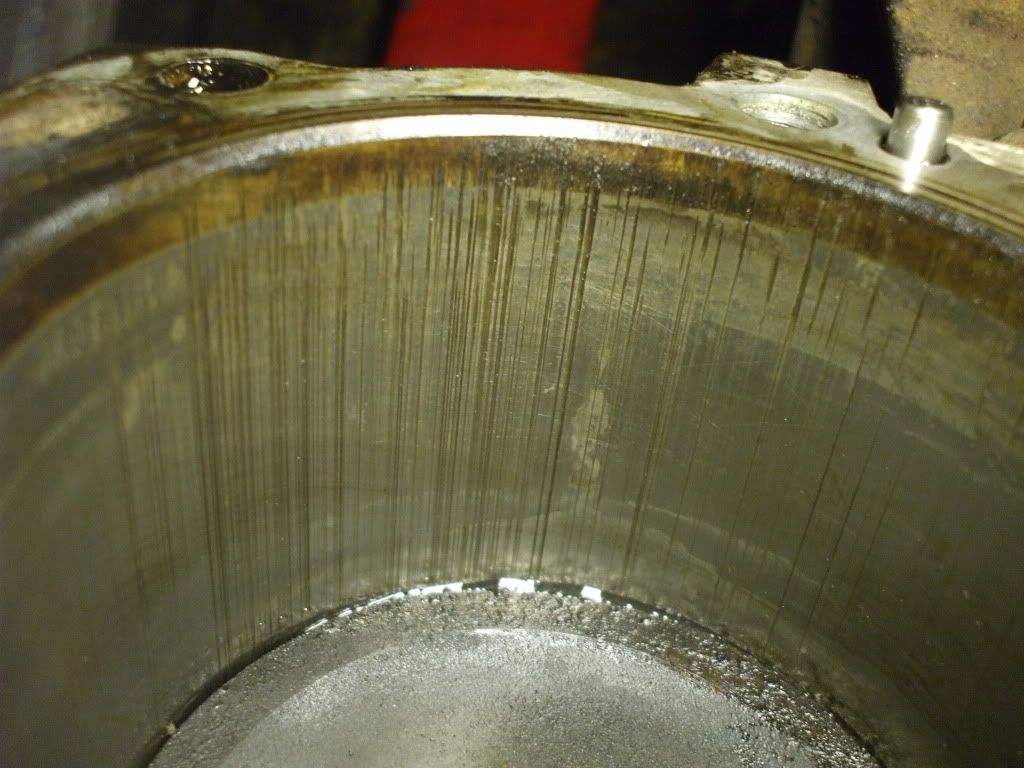

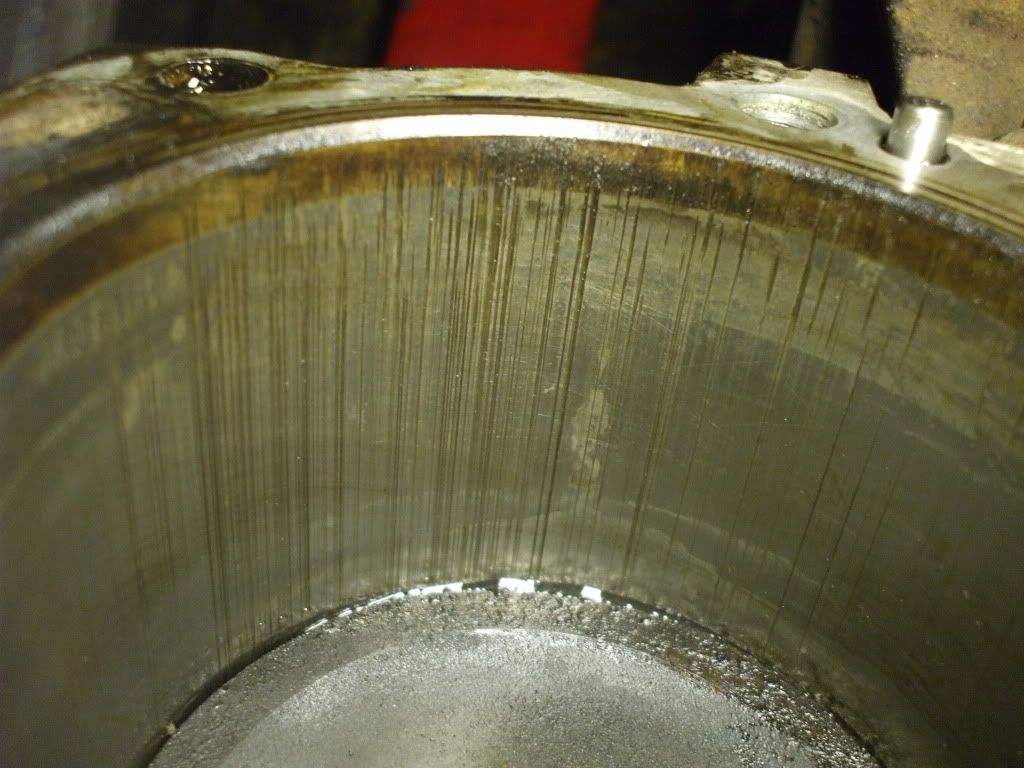

and found the folowing doom and gloom what the hell has caused this? number 1 has the score and its deep may just come out with a 20tho rebore number 2 looks like its had sand in it? and 4 looks like its started to score but would hone

Whats happend here? any ideas? rebore time i recon..

Any body recomend a good engine rebore place in kent? close to maidstonewould be good.

Thanks again

Derek

Posted: Mon Sep 06, 2010 5:27 am

by kiwicar

Hi

Certainly in the secong Photo it looks like the top ring has broken up, from the pitting in the piston crown I would suspect detonation. having said that a rebore will sort it, and it is a good opertunity to get the deck faces squared. As for who to do it, turner engineering are good, Owslebury crankshafts in Winchester are still going after more than 50 years and I think atleast 1 person on here has used them, I am sure there is someone near you who does V8 work to a high standard though.

Best regards

Mike

Posted: Mon Sep 06, 2010 9:57 am

by stagcar

kiwicar wrote:Hi

Certainly in the secong Photo it looks like the top ring has broken up, from the pitting in the piston crown I would suspect detonation. having said that a rebore will sort it, and it is a good opertunity to get the deck faces squared. As for who to do it, turner engineering are good, Owslebury crankshafts in Winchester are still going after more than 50 years and I think atleast 1 person on here has used them, I am sure there is someone near you who does V8 work to a high standard though.

Best regards

Mike

Thanks Mike

I have just made a few calls and found what used to be rovercraft now called Evandan Engineering and there only 6 miles away from me

Quoted £148 +vat for a rebore and the hone with a dip clean.

they will also inspect the crank pluss refit the new pistons on the old rods for me.

I will strip it right out tonight and see what has happend to the pistons.

Thanks again

Derek

Posted: Mon Sep 06, 2010 10:42 am

by kiwicar

Hi Derek

£148 +VAT sounds like a good price to me! Its nice they are so close too.

Best regards

Mike

Naughty Auto box spacer bit :(

Posted: Tue Sep 07, 2010 12:30 pm

by stagcar

Hi,

Next problem has showed up in the form 6 rounded allen bolts on the flexiplate spacer mounted to the back of the crank shaft.

I thought i would remove it while the crank is still in the engine as it is easy to lock the crank using a block of wood.

It looks like some one has been here before and the bolts are in a bad state and are compeatley rounded out i managed to get one to grip but it rounded out like the others

it looks like there made of sxxit..

These bolts seem very tight i have given the center punch idea a go but they dont seem that keen on letting go

Any other ideas on how to get them out? drill the head of and easy out them? maybe cut the spacer up with a grinder then unscrew the bolts with mole grips?

What do you think?

its got to come of one way or another as it is hocking up with a LT77 when done

Thanks again

Derek

Posted: Tue Sep 07, 2010 12:38 pm

by Ian Anderson

Tack weld another bolt / nut on top and then remove with a socket spanner

Or Easy Out may work but if they are that tight will snap

IAn

Posted: Tue Sep 07, 2010 12:48 pm

by stagcar

Ian Anderson wrote:Tack weld another bolt / nut on top and then remove with a socket spanner

Or Easy Out may work but if they are that tight will snap

IAn

Thanks Ian

I will try the weld option tonight. At least it will get them red hot if nothing else

why cant they just use bolts like every other fly wheel i have taken of still that's progress for you.

Thanks

Derek

Posted: Tue Sep 07, 2010 12:53 pm

by kiwicar

As the heads are cearly not fully hardened just drill out the heads lift off the adaptor and now the tension is off then unscrew the bolts.

Best regards

Mike

Posted: Tue Sep 07, 2010 1:00 pm

by stagcar

kiwicar wrote:As the heads are cearly not fully hardened just drill out the heads lift off the adaptor and now the tension is off then unscrew the bolts.

Best regards

Mike

Nice one Mike

I will give it a go and see what happens as you say there soft bolts and very tight. the one that did grip i had a breaker bar on it and was giving it all i had before it rounded out like the others

I will attack them tonight its a battle i could have done with out.

Once this is of i will continue the strip down and see what has happend to the rings.

Thanks again for the help

Derek