major flapper EFI problem urgent need help

Posted: Fri Dec 29, 2006 12:14 am

major problem here

been chatting with tony lots on this one but nothing

the story so far!

new recon block replacing the one with shot piston rings

put inj system back on engine fired up nice but leaked water from a few places

engine ran shite but ran

valley leaked (thought it was the heads so changed the gaskets stopped the leak for a while)

engine wouldnt run between me and tony on the phone we managed to get it to run by disconnecting the extra air valve hose at the plenum

then the engine would run

today my mate paul came over and we managed to get the engine to fire by disconnecting the hose and we got a test meter on the connection to the extra air valve and found both wires to have current all the time found the loom to be cracked then it pissed water again so i replaced the valley gasket again with a genuine one and thats cured the leaks

now ive swapped the EFI loom for a new one and wired it as per tonys flapper wiring diagram on this forum and now the engine wont run again if i disconnect the wire to the coil that fires the injectors it will after a few secconds fire up using the 9th injector then die off

it also wont start if i disconnect the extra air valve hose so im guessing thats working now

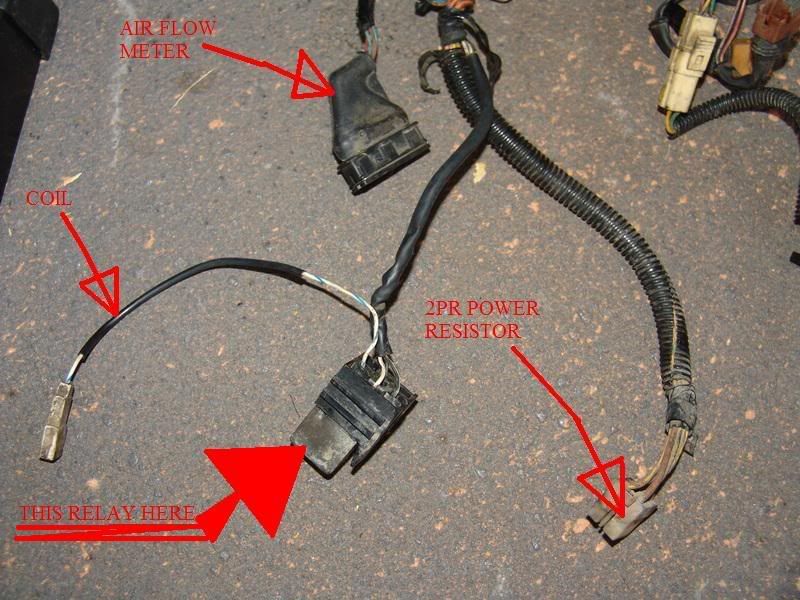

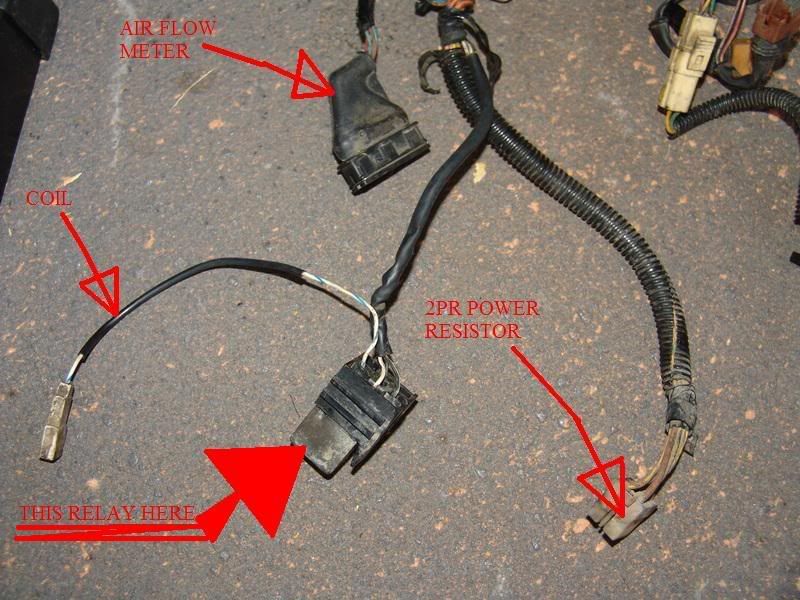

also can anyone tell me what this relay is for?

has anyone got any ideas for me to check

is it possible now its all sealed air etc that the ignition timings now proper far out if i turn it towards the water pump it will try to fire if i spin it away it wont even try

possible im too far off i set it on the number 1 cylinder with the oil pump pto set to the right place in the book by eye this was and the dizzy dropped right in

im all out of ideas and im proper stumped id like to run my new rings in but not if it wont start eh!

the cam was seccond hand off tony and has the right lifters for the lobes so im not too worried about the constant cranking and it has awesome oil pressure

doesnt help my ign though

im pretty convinced that its electrical

before i swapped the loom i did try a new coil

the ecu and air flow meter has been tryed on a different car and these both work fine

been chatting with tony lots on this one but nothing

the story so far!

new recon block replacing the one with shot piston rings

put inj system back on engine fired up nice but leaked water from a few places

engine ran shite but ran

valley leaked (thought it was the heads so changed the gaskets stopped the leak for a while)

engine wouldnt run between me and tony on the phone we managed to get it to run by disconnecting the extra air valve hose at the plenum

then the engine would run

today my mate paul came over and we managed to get the engine to fire by disconnecting the hose and we got a test meter on the connection to the extra air valve and found both wires to have current all the time found the loom to be cracked then it pissed water again so i replaced the valley gasket again with a genuine one and thats cured the leaks

now ive swapped the EFI loom for a new one and wired it as per tonys flapper wiring diagram on this forum and now the engine wont run again if i disconnect the wire to the coil that fires the injectors it will after a few secconds fire up using the 9th injector then die off

it also wont start if i disconnect the extra air valve hose so im guessing thats working now

also can anyone tell me what this relay is for?

has anyone got any ideas for me to check

is it possible now its all sealed air etc that the ignition timings now proper far out if i turn it towards the water pump it will try to fire if i spin it away it wont even try

possible im too far off i set it on the number 1 cylinder with the oil pump pto set to the right place in the book by eye this was and the dizzy dropped right in

im all out of ideas and im proper stumped id like to run my new rings in but not if it wont start eh!

the cam was seccond hand off tony and has the right lifters for the lobes so im not too worried about the constant cranking and it has awesome oil pressure

doesnt help my ign though

im pretty convinced that its electrical

before i swapped the loom i did try a new coil

the ecu and air flow meter has been tryed on a different car and these both work fine