Page 1 of 1

Camshaft retaining plate bolts

Posted: Tue Feb 19, 2008 11:04 am

by Paul V8

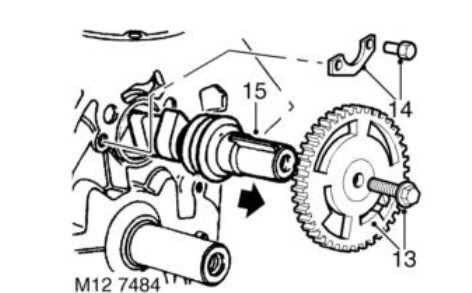

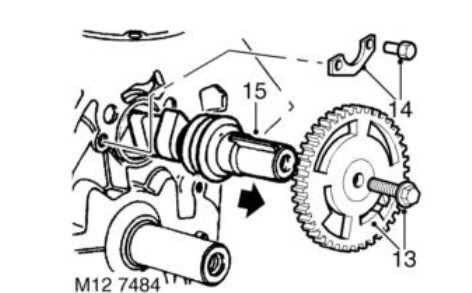

Hello, im fitting a camshaft retaining plate to my rover, the bolts im using are 5/16 unc, once fitted with a washer the bolts rub the back of the cam sproket. Am i doing something wrong or is there a special bolt??

Thanks.

Posted: Tue Feb 19, 2008 11:17 am

by ian.stewart

Got a Piccy??

Re: Camshaft retaining plate bolts

Posted: Tue Feb 19, 2008 11:40 am

by sidecar

Paul V8 wrote:Hello, im fitting a camshaft retaining plate to my rover, the bolts im using are 5/16 unc, once fitted with a washer the bolts rub the back of the cam sproket. Am i doing something wrong or is there a special bolt??

Thanks.

RPI have just sent me a set of bolts along with a new plate, there were no washers supplied. Try leaving the washers off!

(The bolts that they sent me were not 'special'. I have not fitted the plate yet so I can't say whether I'll have the same issue)

Pete

Posted: Tue Feb 19, 2008 12:17 pm

by russell_ram

No washers is correct. Original bolts have 'patch lock' for retention.

End float spec is 0.075 to 0.25mm. Although even if it's a bit bigger, I would say it's a million times better than no retaining plate and relying on the chain (and oil pump) to locate it.

Russ

Posted: Tue Feb 19, 2008 1:39 pm

by Paul V8

Its now on there with no washers and all seems ok, i phoned Paul at V8 TUNER who said the same, no washers, maybe just a touch of thread lock.

Thanks.

Posted: Thu Feb 21, 2008 9:21 pm

by sidecar

Paul V8 wrote:Its now on there with no washers and all seems ok, i phoned Paul at V8 TUNER who said the same, no washers, maybe just a touch of thread lock.

Thanks.

Funny that you should say that your plate is OK as I've just fitted mine and the bolts hit the sprocket in a big way

My sprocket is a piper vernier jobbie and to get the bolts to clear I had to very carefully grind down the vernier bolts where they protude through the back of the sprocket AND grind the retainer plate bolts heads down until they where about 1.25mm thick.

Even now there is only 0.5mm clearance when the cam is pushed back as far as it will go. (measured this by poking bits of wire through the holes in the sprocket)

Why does every thing I go take 10 times longer than I planned?

(Two hours just to fit and time up the cam)

Oh, by the way I came up with what I thing is a good idea to stop the cam lobes scratching the bearings as you fit the cam.

I wrapped a strip of insulation tape round each lode and left a bit of the tape doubled back on its self so is could grab it with some needle nose pliers once the cam was fitted. Obviously the cam lobes must be lobed up after it has been fitted or the tape won't stick!

Regards,

Pete