Page 1 of 1

Wasted Spark on RV8

Posted: Tue Dec 11, 2007 7:13 pm

by deetes

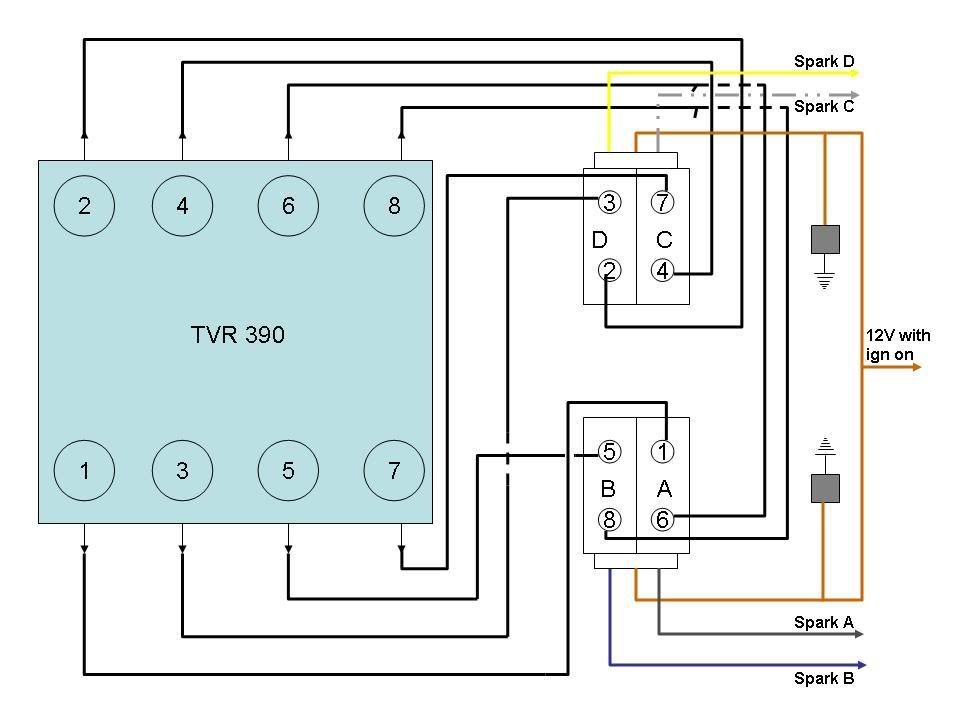

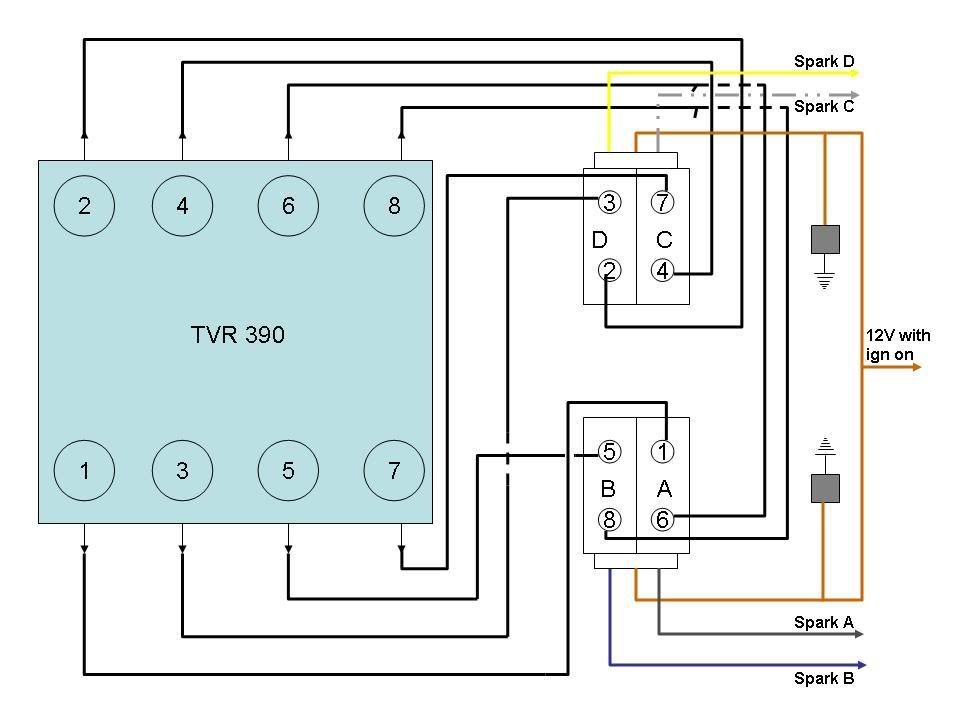

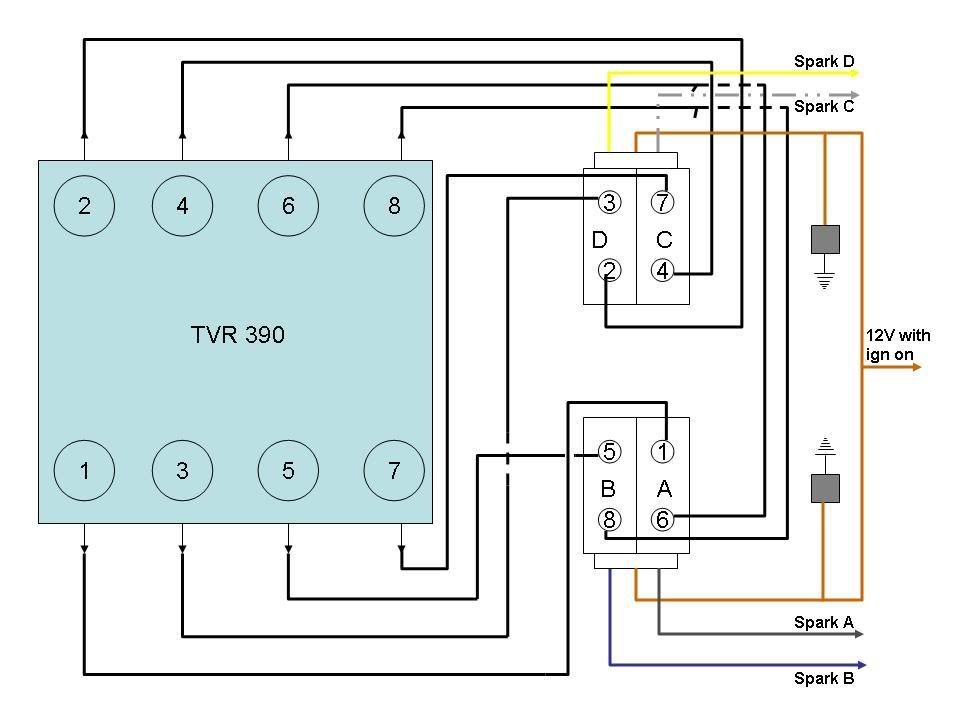

Does this look about right for RV8 with wasted spark on MS?

Posted: Tue Dec 11, 2007 9:32 pm

by ChrisJC

High Tension side is spot on.

Chris.

Which coilpacks?

Posted: Thu Dec 13, 2007 3:32 pm

by jefferybond

Im also thinking of running wasted spark (already running megasquirt for sparks).

Which are good coilpacks to use? I want something with simple HT towers, so that I can easily make up a new set of leads. Ideally, coilpacks which have HT terminals that look just like the old dizzy cap terminals would be good.

I was thinking along the lines of Zetec Mondeo coilpacks (motorcraft), but only judging by photos on ebay! Are these easy to use?

Cheers,

Jeff

Posted: Thu Dec 13, 2007 4:42 pm

by ian.stewart

I was looking at the ford ones as well, Accell do a direct replacement for the ford coil and I think it gives a bigger spark as well, I have yet to look into the leads thing, but I can see your logic with the type of tower tops needed

I assume both of you are running serp front ends??? if not, what are you going to do with the Dissy??

Posted: Thu Dec 13, 2007 6:02 pm

by deetes

http://www.performanceleads.co.uk/

These guys do leads to fit the ford coil packs. You tell them the lengths and they make them up pronto.

The ford coil packs are readily available from any breaker. Get the wiring, the condensors(think that's what it is) and the plugs for both.

Not running Serp front. Will leave the dizzy in place unless I can figure out how to cut it down, but still drive the oil pump. Anyone doing dizzy plugs for these older models?

Posted: Thu Dec 13, 2007 6:14 pm

by Coops

have any of you tried contacting these guys that offer you discount?

http://www.v-8.org.uk/forum/viewtopic.php?t=54

Posted: Thu Dec 13, 2007 6:16 pm

by ian.stewart

Just done a conversion on my dissy, you do have to have acess to a lathe as it needs to be turned down so a cap can be fitted to cover the stub of the shaft, stop oil leaking and the ingress of dirt

Thrust loads of the shaft run up the dissy so the need for an extra thrust bearing at the top is negated, but you do need to make sure the stub of the housing is clamped in firmly, if not the stub will rise out of the oil pump and you will totally lose oil pressure!!!!

If I can I will try and post pics if you want but I have failed recently to download any pics

Posted: Thu Dec 13, 2007 7:58 pm

by Eliot

deetes wrote:http://www.performanceleads.co.uk/

These guys do leads to fit the ford coil packs. You tell them the lengths and they make them up pronto.

The ford coil packs are readily available from any breaker. Get the wiring, the condensors(think that's what it is) and the plugs for both.

Not running Serp front. Will leave the dizzy in place unless I can figure out how to cut it down, but still drive the oil pump. Anyone doing dizzy plugs for these older models?

Thats who i used for my edis leads too. Although, its easy to remove the ends from the ford leads and make your own up.

Had a similar problem with my dizzy, just got a old dizzy and cut it down so it stll ran the pump (chevy)

Posted: Fri Dec 14, 2007 10:08 am

by deetes

Thanks for all the replys everyone.

Ian, perhaps you could send a picture direct to me if you can't post it on the forum.

Eliot, I'm sure it was something on your website that put me onto the guys with the leads anyway.

Posted: Fri Dec 14, 2007 10:39 am

by chodjinn

I have just got two of the accell coil packs to run with my set up. ALso have two Ford motocraft coil packs spare if anyone needs some.

As for the dizzy, I just choppe the top off with an angle grinder and botched a cap to go over the top.

Ian, what's all this about clamping the housing in place? You got me worried now! I have cut my housing off a couple of inches above the hole in the front cover. Wont be an issue when the dry sump is fitted but that's not happening for some time yet!

Posted: Fri Dec 14, 2007 2:48 pm

by deetes

Are the Accel coil packs much better than the ford ones?

Need to see if I can get my hands on an old dizzy so that I can cut it down. I'll have to have a look and see which one it's got.

I believe that there were some differences with the oil pump drive, is that correct?

Next would be to source one, preferable a shot one, as there's no point in cutting up a good one, unless there's loads of them going about.

Posted: Fri Dec 14, 2007 4:17 pm

by ian.stewart

Clamping the dissy down is only really what you use in the normal situation, its the same set up, but I was worried that possibly somebody may think if there is no dissy top there is no need to clamp it securely,

If you take the shaft and gear out completely I think you will need to run a cam button as its the resistance from the oil pump that provides a resistance to load the cam gear and drive the cam into the engine which stops it walking about. I think that makes sense, dont serp engines have a keep plate to stop the cam walking.