Page 1 of 2

Mixer Ring - Gotta be a restriction

Posted: Sun Dec 09, 2007 1:59 pm

by stirlsilver

Hi all,

Been ages since i've posted here, but I haven't been doing all that much with my V8 for a while... Anyway, I just recently changed my intake manifold to an EFI type and in swapping the gas mixer ring I realised how much of restriction it would be on the intake!!!

Obviously the ring works on the venturi effect to create a vacuum, BUT having such a square profile doesn't help the fact that it's a reduced area.

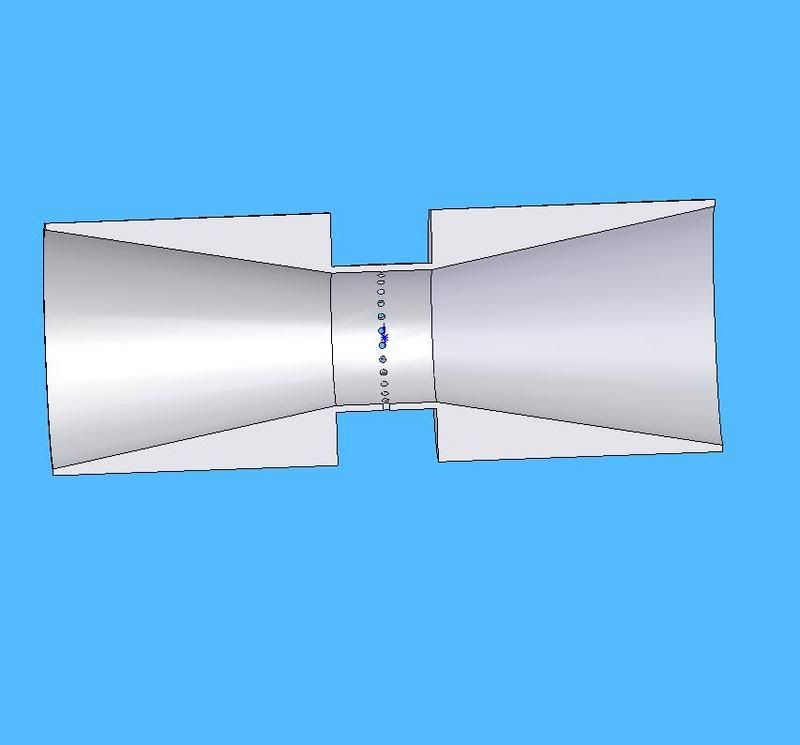

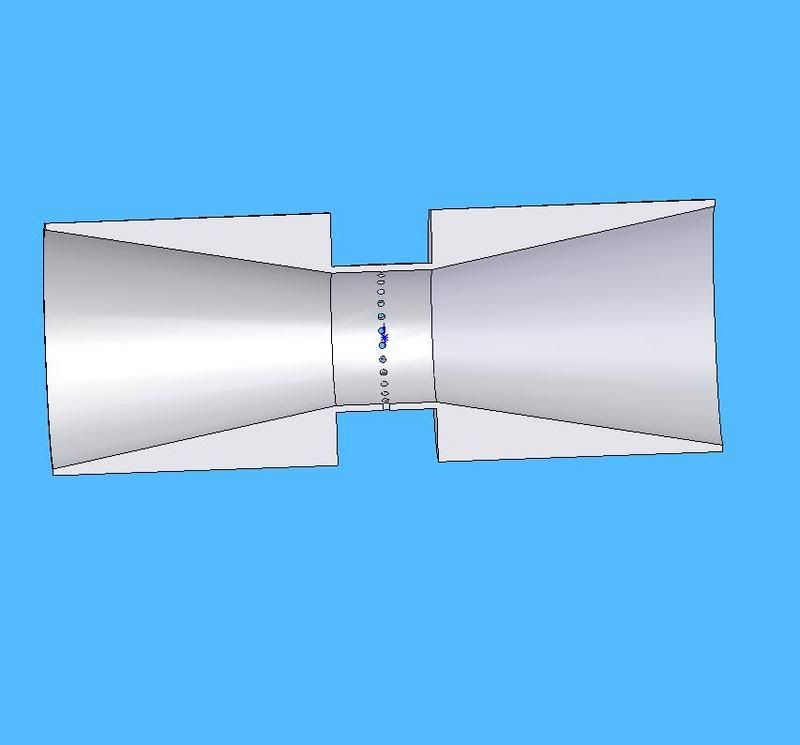

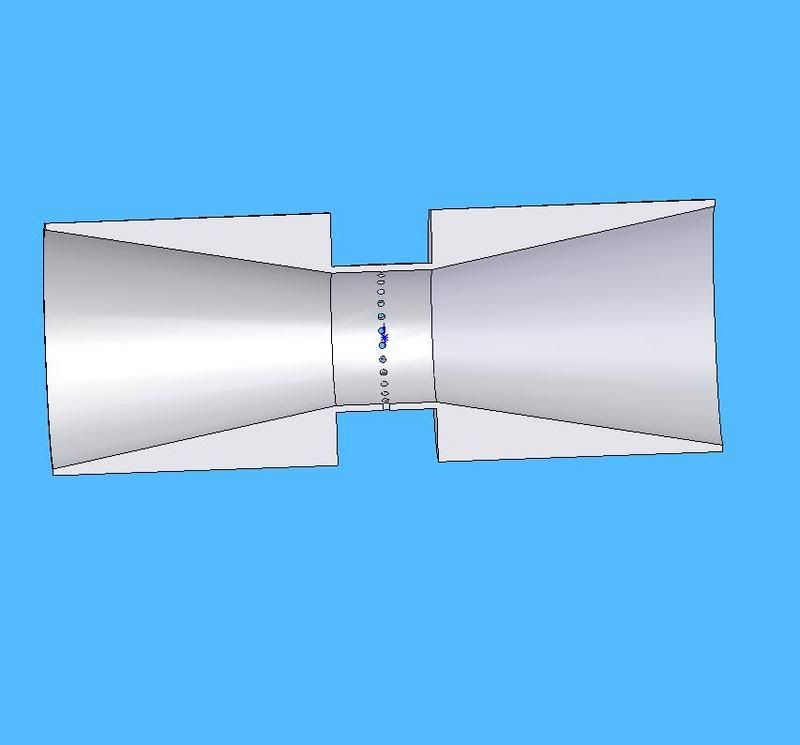

I was thinking of machining one up for myself that is about 150-200mm long with a nice smooth taper to the necessary orifice size and back down like in the diagram below:

However I have realised that the current mixer ring uses the turbulent flow behind it to mix the gas and air together which wont be achieved with this design... Any thoughts anyone?

I appreciate any input!

Stirling

Posted: Sun Dec 09, 2007 3:30 pm

by ChrisJC

The mixer ring I have has a much larger hole in it. I did find however that although performance was much improved over the previous smal-hole type, I had some difficulty in setting the idle mixture (in fact it's still not that good).

Basically there isn't enough venturi effect at idle to draw gas from the vapouriser. So therefore it relies on the idle screw mixture screw which just dumps a fixed amount of gas in.

There still isn't enough venturi to draw gas at slightly above idle speeds either, so as the engine picks up, the mixture leans out until the speed is high enough (i.e. enough venturi effect) to start pulling on the diaphragm in the vapouriser and hence a bit more gas. When driving it's fine.

The fix I guess is to get a softer spring in the vapouriser, but I couldn't get any joy on that one.

Chris.

Posted: Sun Dec 09, 2007 10:13 pm

by bill shurvinton

vapourisers are by definition a major compromise. You have to live with that or go gas injection. There are improvements that can me made, but you are polishing a turd.

Posted: Sun Dec 09, 2007 10:34 pm

by stirlsilver

Yes, I understand that Amos Ring type systems are a compromise as a result of using the venturi effect. Having the throat narrow down and expand back up smoothly will greatly reduce the restrictive effect that a narrow opening has.

Conventional mixers rely on the turbulent flow behind them to mix the gas and air together, the flow behind this mixer ring will be laminar. What I am asking here is will I be able to get away with sufficient enough mixing considering the flow has a 90 deg turn, the throttle body and plenum chamber to negotiate after the mixer ring.

Posted: Tue May 26, 2009 8:40 pm

by oilyfingers

How did you get on with machining the new design of mixer ring?

flow gas mixing

Posted: Wed May 27, 2009 2:20 pm

by Dangerdoc

Well couple of thoughts.

I remember reading somewhere about "cyclone" devices that mix the air and gas better as they create turbulent flow - that's one suggestion - incorporating one into the downstream side of the mixer.

Other suggestion is to think like a form of flame trap idea - that is to incorporate a mesh layer on the downstream side, nothing so dense as a flame trap but just enough to create flow disturbance and air mixing.

Not sure if these are totally mental absurdities but just a couple of thoughts that might spark some train of thought with others.

Not sure about polishing turds though

that might not be a great idea.

Doc

Posted: Wed Jun 03, 2009 10:00 am

by mcgill

all my v8s have the mixer on the end of the air filter,between the afm...

??

Posted: Wed Jun 03, 2009 8:41 pm

by Dangerdoc

Hey McGill

What is your message and why the incomplete reply. What is key here is for information that can develop the design further and with more efficiency.

Your abbreviated message does not make things clear matey peeps.

Doc

Re: Mixer Ring - Gotta be a restriction

Posted: Wed Jun 10, 2009 1:54 pm

by bobtail84

stirlsilver wrote:Hi all,

Been ages since i've posted here, but I haven't been doing all that much with my V8 for a while... Anyway, I just recently changed my intake manifold to an EFI type and in swapping the gas mixer ring I realised how much of restriction it would be on the intake!!!

Just to go back to the original question and maybe help a bit and I did say maybe..

I have a 3.9 with Mega Squirt and LPG with the same gas mixer ring and have just finished helping a mate Squirt his 3.9 in a LR90 and before you all cry its not a go faster motor let me explain.

We are going to data log the engine on a set route on petrol and record it on the laptop. Then we are going to fit the mixer with the gas entry blocked and repeat the set route as best we can. We can then run the logs through MegaLogViewer and analyse the change to the fuel map as regards the air flow mixture ie: if it wants to make the fuel map weaker due to the air restriction or it makes very little difference. I can also monitor the O2 sensor and watch to see if it runs lean or rich.

With out going into to much technical fu-fu the MegaLogViewer is a program that is very similar to a rolling road except you drive around on the Queens highway (at legal speeds of course...

)

Will let you know soon.

Jeff

Posted: Sun Sep 06, 2009 12:05 pm

by stirlsilver

Sorry everyone,

I sorta left this thread hanging there. It's been a while since i've been on this forum. I actually manufactured the mixer ring and installed it. I'm just copying and pasting part of the thread here, June 2008:

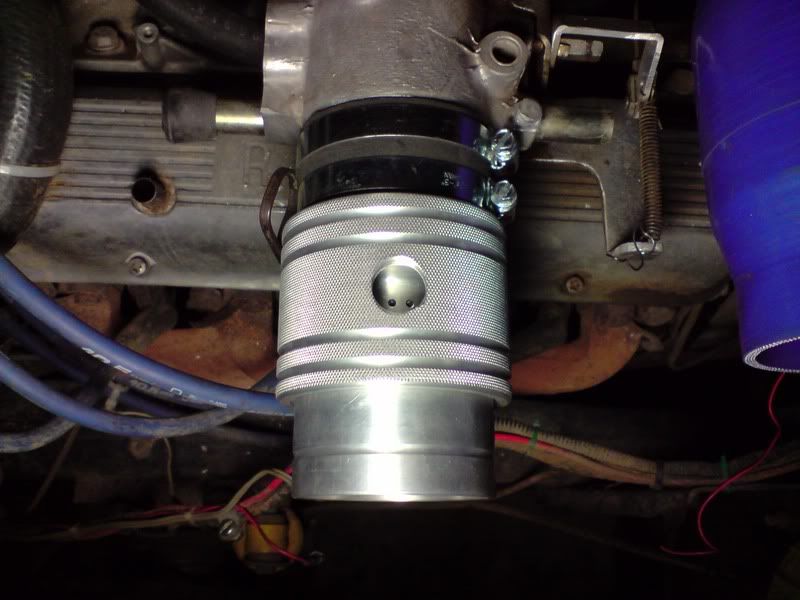

I took off the old mixer ring from my intake manifold

Here is the comparison of the old mixer ring with the new one which I designed:

And I then started fitting the new mixer ring onto the engine.

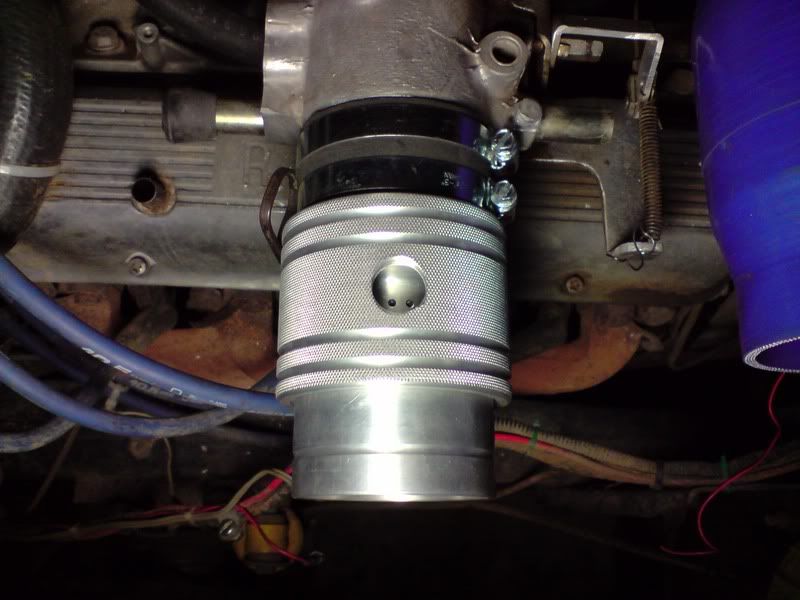

The core of the mixer:

O-rings

The collar, this was so hard to get on with 4 O rings!:

And finally the brass fitting for the gas feed:

Flexible 3" pipe to join it all together:

The mixer ring was a partial success, the engine did respond much better with this ring, however it isn't perfect. At full throttle openings you don't get the mixing effect of the butterfly and the lpg doesn't mix with the air properly, and since I was using an EFI manifold with trumpets in the plenum I suspect that at WOT the air fuel ratio varied across cylinders. It was actually not that noticeable but i'm pretty sure that this design isn't ideal at WOT.

The engine was perfectly drivable though and I have been using it for the last 10 or so months without issue... until I broke my transfer case a couple of months ago, but that is a different story.

I've started a new project car and I'm thinking of doing a twin turbo 3.9L engine on LPG as well... This style of mixer will work just fine on a suck through setup because the compressor on the turbo will ensure that the air and fuel always mixes, no matter what the position of the throttle body is.... anyway, that is all a long way off yet, I gotta finish building up the rear wall on the car (I cut a discovery in half!).

Posted: Sun Sep 06, 2009 6:44 pm

by ChrisJC

Very nice job.

Not sure about a suck through turbo, you'll definitely need a blow-off valve for those inevitable backfires!!

Chris.

Posted: Mon Sep 07, 2009 4:16 pm

by v8dolphin

should the vapourizer be facing east west rather than north south this might help when acc. or braking hope this helps

Posted: Mon Sep 07, 2009 4:26 pm

by topcatcustom

Wow nice work, could you fit a fan type blade just after the ring to stir up the mix? Maybe even a round plate with a couple of big louvre type slots would work...

Posted: Wed Sep 09, 2009 12:53 pm

by stirlsilver

v8dolphin wrote:should the vapourizer be facing east west rather than north south this might help when acc. or braking hope this helps

Yeah I did notice this actually. If you ever did an emergency brake, the engine would get flooded with LPG and cut out on you... Never thought about the leaning out effect on acceleration though... But yeah you are right, it should be East/West, I don't know why the installers put it in that way.

Posted: Wed Sep 09, 2009 12:56 pm

by stirlsilver

topcatproduction wrote:Wow nice work, could you fit a fan type blade just after the ring to stir up the mix? Maybe even a round plate with a couple of big louvre type slots would work...

Yeah you could do that, but then you are simply reintroducing restrictions that this design would have eliminated... I suppose a better way to do it would be to have multiple rings so you are introducing gas in a number of locations across the opening, but that is getting very very tricky!

I think i'll just skip all that and use the turbos to do the mixing