Page 1 of 1

Fitting

Posted: Tue Jan 24, 2017 3:06 pm

by BISH V8

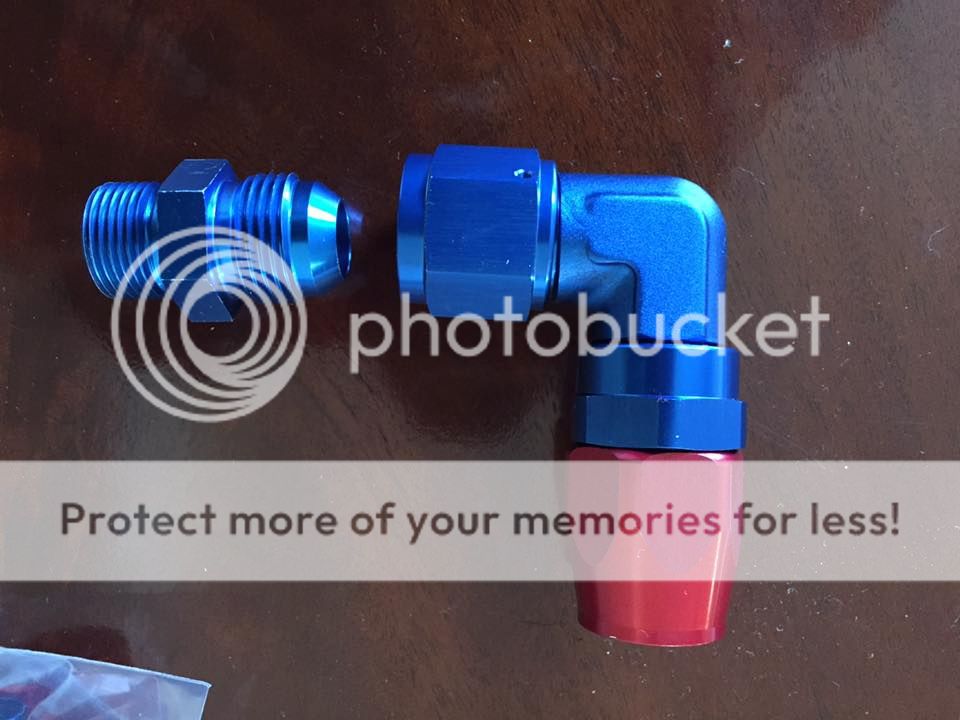

Just annoyed you can't buy what you need, anyone out there can you get a m20 1.5 pitch male to an10 male elbow, this is what I got but hits chassis...

ot but hits chassis

Posted: Tue Jan 24, 2017 7:11 pm

by Denis247

If it was male to male you couldn't control it's position when fitted. The output might face completely the wrong way, assuming it's going into something solid of course and not just joining two pipes.

Posted: Wed Jan 25, 2017 11:52 pm

by unstable load

I don't know about M20 thread, but you do get them in NPT sizes.

MS20822 is the aviation part number for the elbow, the dash numbers will denote the sizes of the fitting.

http://aircraftproducts.wicksaircraft.c ... ow-fitting

Posted: Thu Jan 26, 2017 5:25 pm

by stevieturbo

Posted: Fri Jan 27, 2017 8:56 pm

by BISH V8

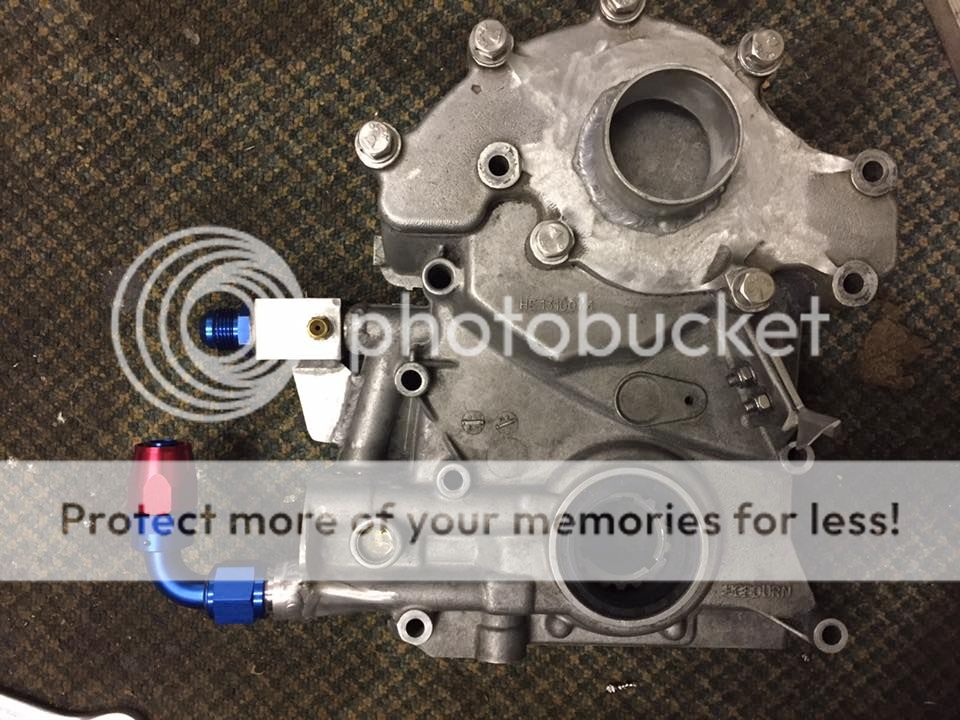

Decided to modify the oil supplies as I didn't want to go the banjo route as I wanted to have no restrictions on the flow, ended cutting an inch off the return

and welding a AN1O on which now I have plenty of room for oil pipes/fittings

Posted: Fri Jan 27, 2017 9:07 pm

by stevieturbo

Given the many 90deg drillings within the oil galleries in the system, I wouldnt see a banjo being a problem at all.

Welding direct is the neatest option though. But even with say -10...the actual orifice in a lot of fittings can be much smaller than you'd like.

For my oil lines I ended up having to use -12 just to ensure no fitting/pipe was smaller than the oil galleries in the engine itself.

Oil galleries were around 12.5mm, a -10 fitting would have dropped that to around 11.5mm whereas -12 was about 14.5mm

The hoses were all large enough, just the fittings themselves dropped the bore down.

Posted: Fri Jan 27, 2017 9:44 pm

by BISH V8

The hoses were all large enough, just the fittings themselves dropped the bore down.[/quote]

There are quite a lot of fittings that look the same but don't do the same job, fast flow/forged made of one piece all to help the process of flow, plumbing by trade I realise flow restrictions on certain fittings, a banjo compared to a forged elbow I believe a banjo would cause quite a bit of cavitation and restriction compared to a forged elbow, anything that can help the flow of oil has to be a help

Posted: Fri Jan 27, 2017 9:49 pm

by stevieturbo

BISH V8 wrote:The hoses were all large enough, just the fittings themselves dropped the bore down.

There are quite a lot of fittings that look the same but don't do the same job, fast flow/forged made of one piece all to help the process of flow, plumbing by trade I realise flow restrictions on certain fittings, a banjo compared to a forged elbow I believe a banjo would cause quite a bit of cavitation and restriction compared to a forged elbow, anything that can help the flow of oil has to be a help[/quote]

The smallest bit is usually the bit that extends into the flexible portion of hose. No way around that really other than using larger fittings.

The banjo

may pose more of a restriction that a typical swept fitting etc...but again, as all the internal oilways are full of sharp 90deg turns. I wouldnt be concerned about it. The banjo probably flows a lot better than those.

Although I always try and get a burr inside the oil galleries to try and smooth any turns as best as possible. Some just cant be reached though. Probably not needed...but they always bug me lol