Page 1 of 1

piston to bore clearances - problem

Posted: Mon Aug 08, 2016 5:46 pm

by Seight-V8

hello all,

todays problem is piston to bore clearances....

I've had my block top hatted by chesmans earlier in the year, for which I supplied them with my pistons, which are +0.020ins so 94.50mm ish.

Only just getting around to re-assembling everything, as I've been fitting a new kitchen....

Looking in the LR manual its states piston to bore clearances of 0.02 to 0.045mm.

Measured my pistons at 94.440mm smallest and the bore bores at 94.525 largest....

So it looks like I have 0.060 to 0.085mm between piston sizes and the bore sizes....

Question is, if the piston to bore clearance is checked on one side only like the land rover manual page 32?....then i have a major problem with either my piston size or my block bored size.

Can I even think about putting these two items together?????...how bad is the piston slap likely to be?.

What do I do now?.....new pistons or back to chesmans?

I am beginning to think to worst for my block.

cheers

scott

Posted: Tue Aug 09, 2016 6:54 pm

by kokkolanpoika

I build 4.6 top hat engine to my friend. We make 0.06mm clearance and 4.0 pistons with 11.1CR. No piston slap hearing.

I also build my landy 4.6 top hat engine, 2nd hand 4.6 piston´s and CR ratio will be 10.5CR if use tin gasket. And it has got also 0.06mm clearance. Not yet finished engine. So i cant say yet if those piston will make any noise..

My 5.2l engine has got forged pistons, 0.1mm clearance, it has got very small piston slap when engine is cold say approx +10c, over that, you wont hear it..

Oil consumption is another story then if you run 0.08mm clearance.

Posted: Tue Aug 09, 2016 11:10 pm

by stevieturbo

0.06 to 0.085mm is around 2.3 to 3.3 thou.

Really doesnt sound like anything to worry about to me although clearance required can vary with piston type/materials etc.

Posted: Thu Aug 11, 2016 6:11 pm

by DEVONMAN

You haven't stated what type of pistons you are using, forged or standard factory type.

Forged pistons need more cold clearance as they expand more than factory pistons.

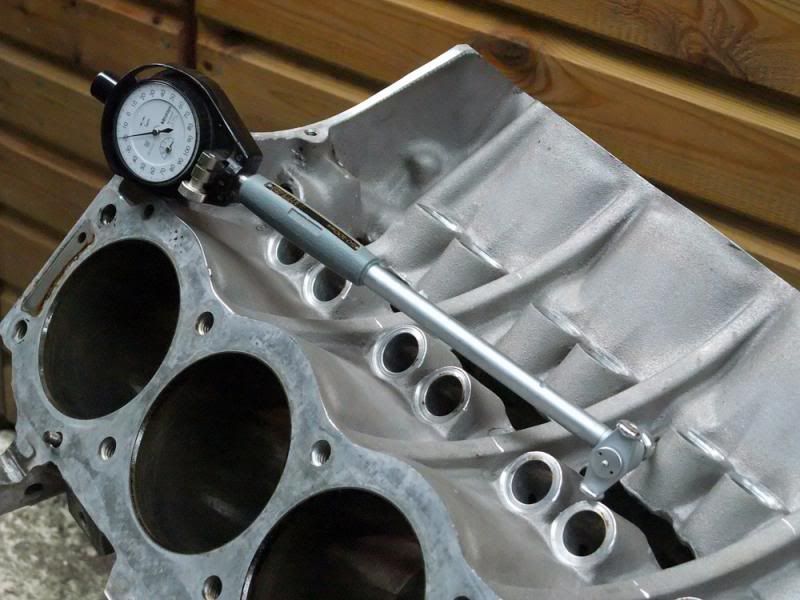

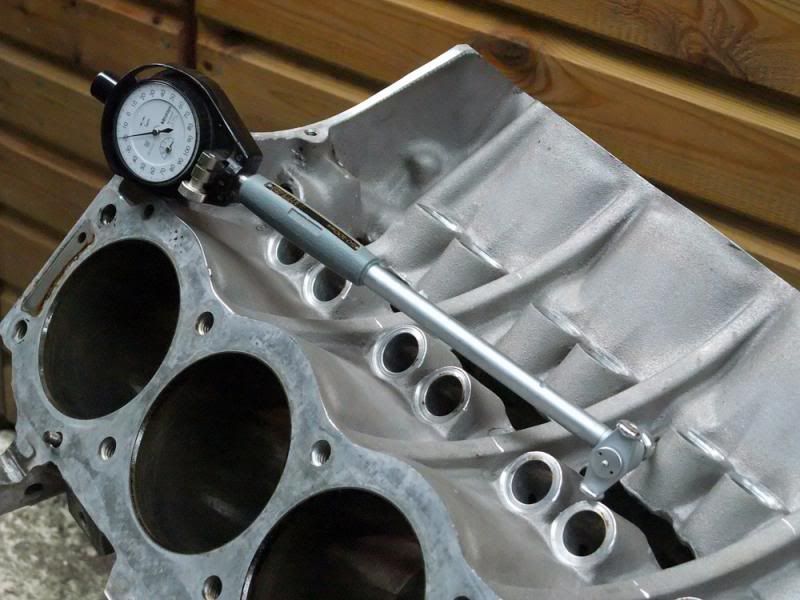

Its difficult to measure the bore accurately unless you have a bore gauge.

In new bores, I normally put the piston in upside down in the bore and use a feeler gauge to measure the clearance between the skirt and the bore.

I do this before the piston rings are fitted.

If the con rods are not yet fitted I use a cable tie around the wrist pin to hang the piston in the bore.

Posted: Thu Aug 11, 2016 7:58 pm

by Seight-V8

all,

I'm quite lucky that I measure things for a living, and have access to all types of measuring equipment.

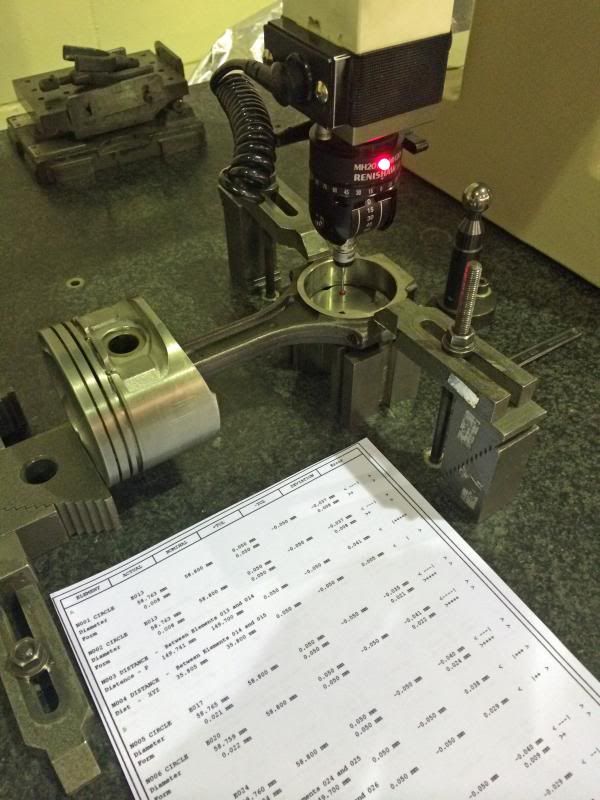

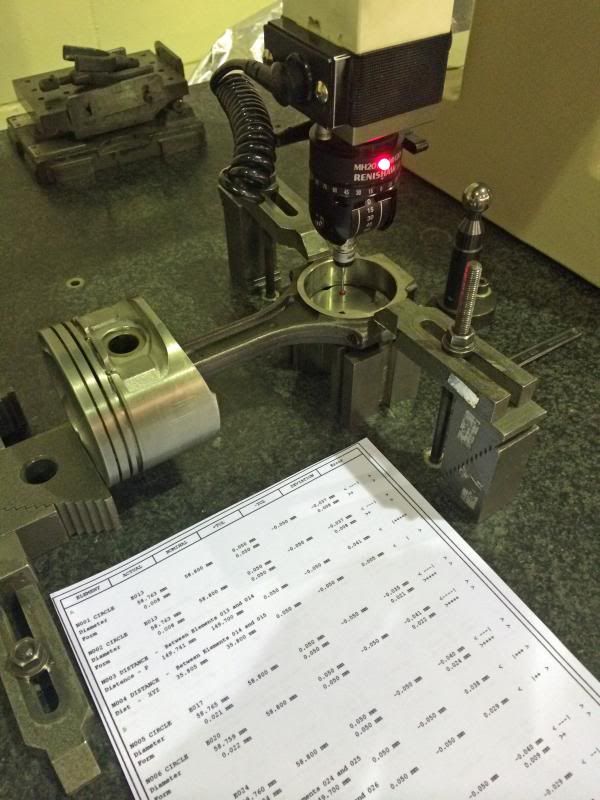

I measured the pistons with the most accurate machine we have, which is capable of 0.0002mm.....yes overkill I know.

then the bores with a bore gauge set for 94.50mm....

I'm quiet confident that the measurements I've taken are correct.

I've spent a few days reading up and looking for info, even des hammills book on v8 engine states that the factory clearance is too tight, and that 0.063mm is more realistic...

I'm using +0.02ins 4.6 cast pistons from real steel by the way, nothing special really.....maybe cheap, thats why they don't even meet grade B sizes....

Don't think that's anything to worry about either, as long as the clearances are ok, and this looks to be the case....

worry over hopefully for now, till the next part of the build.

thanks all.

scott

Posted: Thu Aug 11, 2016 8:21 pm

by ged

I measured the pistons with the most accurate machine we have, which is capable of 0.0002mm

Hi Scott,

Out of interest what machine?

Posted: Fri Aug 12, 2016 6:34 am

by unstable load

I'd be happy with that clearance, personally.

Have a look at the ring gaps and make sure the lands are well cleaned in the pistons and you should be good to go.

Posted: Fri Aug 12, 2016 4:18 pm

by Seight-V8

ged,

its a trimos THV, used as part of our companies metrology equipment.....

To get the best out of this machine.....the environment has to be correct.....and your best not touching the pistons as this can warm them up....

We mainly use it for the calibration of plug gauges for the shop floor, that normally have an accuracy of +/-0.001mm.....

So good for piston measurement, but at 20k new....not worth it for most people.....most micrometers & verniers are only 0.01 to 0.02mm accurate a the best of times......

regards

scott

Posted: Fri Aug 12, 2016 5:44 pm

by benjai

Absolutely nothing wrong with taking accurate measurements...

FWIW I measured my pistons at about 0.075mm clearance and on advice from several people decided to re-use them rather than re-bore... Mind you, I've not fired the engine up yet...