Page 1 of 1

Cam position sensor

Posted: Sat Mar 14, 2015 1:26 pm

by DaveEFI

I'm intending making a cam position sensor out of an RV8 dizzy - a DLM - and would welcome tips so I don't just re-invent the wheel. Only really have hand tools - no lathes or surface grinders, etc. Would like it as small as practicable, though.

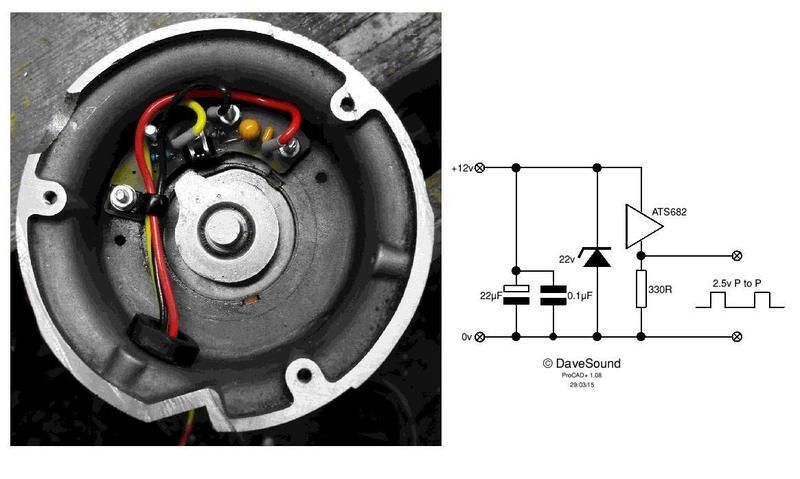

Have some Allegro ATS682 hall effect gear tooth sensors in stock so would be nice to use one of those. The spec sheet says approx 1-3mm air gap will be ok.

Posted: Sat Mar 14, 2015 10:32 pm

by stevieturbo

Really the easiest, is just to use OEM dizzy trigger setup and remove teeth from the trigger as required.

But obviously this still leaves a full size dizzy up top

Presumably it's an RV8 that needs to retain a dizzy shaft to drive the oil pump ?

If so, obviously this is going to add machining requirements etc

ie housing, shaft, bearings, then some sort of tooth setup up top and a mount for it all.

If the sensor you're using is a long threaded type.

As a temp measure before I fitted the proper camwheel with a dizzy on my LS, I "improvised" a phase trigger using a hall sensor pointed at the tip of the roller rocker.

It was simple, only required work to the rocker cover to install and seemed to work ok.

I opted to ignore cam signal once it was sync'd up, as knew overall it wasnt a great setup. But it was cheap quick and easy to make.

If doing that approach again I'd probably aim the sensor directly onto the top of the spring and if you're using steel spring retainers this should be very easy.

Mine are Ti so this did hamper the signal a little hence I opted for the steel roller on the rocker instead.

Posted: Sun Mar 15, 2015 10:12 am

by DaveEFI

I've made a stumpy drive, so can cut down a dizzy with hand tools.

The ATS682 sensors I have are just a bare IC - no mounting. About the size of a little finger nail.

My idea is to gut the dizzy, and cut down the plate attached to the main shaft that the springs fit to into a suitable single 'spike'

Cut off the shaft above that, cut the body just above than and make a flat top from ally.

Posted: Wed Mar 18, 2015 12:54 am

by kusanagi

I don't know if its any help but what I did to make my cam position sensor was I used an old points distributor (though you could use an electronic distributor) and gutted the all the internals (advance mech, etc) and made a post fitted with a half moon disc that is fitted to the original distributor shaft this then triggers an old luminition optronic sensor (this works fine on the 5Volt feed) to give me my cam position.

Posted: Wed Mar 18, 2015 9:23 am

by Spongo

If you want a really accurate Cam position then using a dizzy may not be the best idea given the amount of slack in the timing chain and associated drive.

There is a CAM position sensor on the GEMS engines I believe might be worth investigating if that can be used

Posted: Wed Mar 18, 2015 9:56 am

by DaveEFI

Doesn't need to be accurate. All it has to do is to tell MS where the engine is in the four stroke cycle. The crank position one gives the accurate information for timing.

Posted: Sun Mar 29, 2015 12:50 pm

by DaveEFI

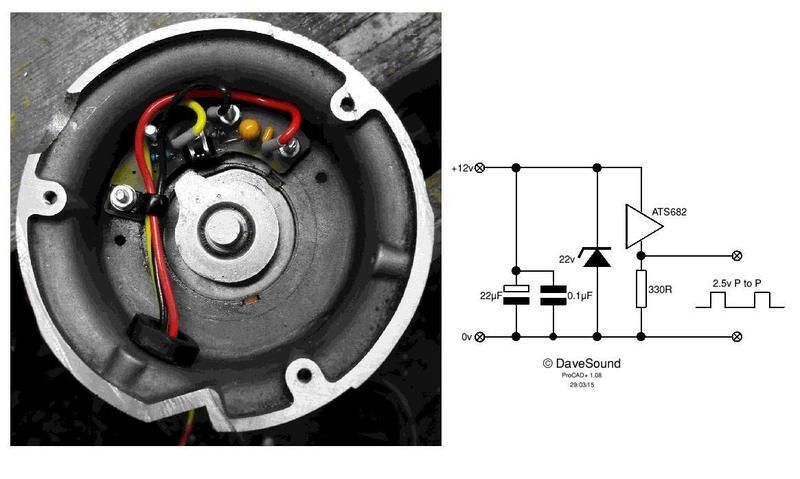

This what I ended up with. Zero cost since I already had all the bits. Removed everything which came off the dizzy, and cut down the plate on the end of the main shaft to make a tooth. Sawed off the top if the casing to accept a flat plate.

Posted: Sun Mar 29, 2015 1:55 pm

by JSF55

Good looking set up