Page 4 of 14

Posted: Sun Jun 05, 2011 5:31 pm

by Mark

stevieturbo wrote:That's why I just paid someone else to do it lol

I can accept when I'm in over my head. Looking good though

Knowing now how much work and expense (buying a welder) it has been I would rather of paid OJZ to do it!

Posted: Sun Jun 12, 2011 6:25 pm

by Mark

At last the headers are finished

On the down side, I've taken a deposit on my bike to free up some cash to keep the project going.

Now I will have to drive to work in a Fiat

Posted: Mon Jun 13, 2011 8:57 pm

by JJMclure

Nice! Looks like a full akrapovic system on the yamaha? Always wanted but could never afford one when I was into bikes.

Sorry to hear about the fiat....

Posted: Sat Jun 18, 2011 6:09 pm

by Mark

JJMclure wrote:Nice! Looks like a full akrapovic system on the yamaha? Always wanted but could never afford one when I was into bikes.

Sorry to hear about the fiat....

Yes mate, it had the full Akro system, de-restricted inlet manifolds, 4 degree ignition advancer, K&N with modified airbox. Was a really good arm stretching device

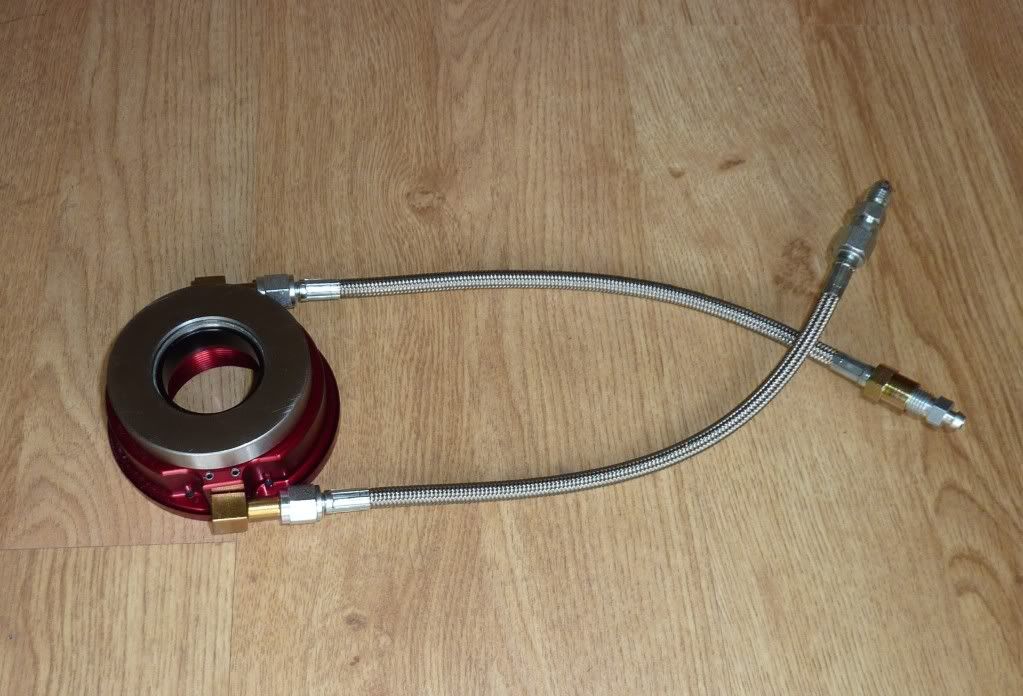

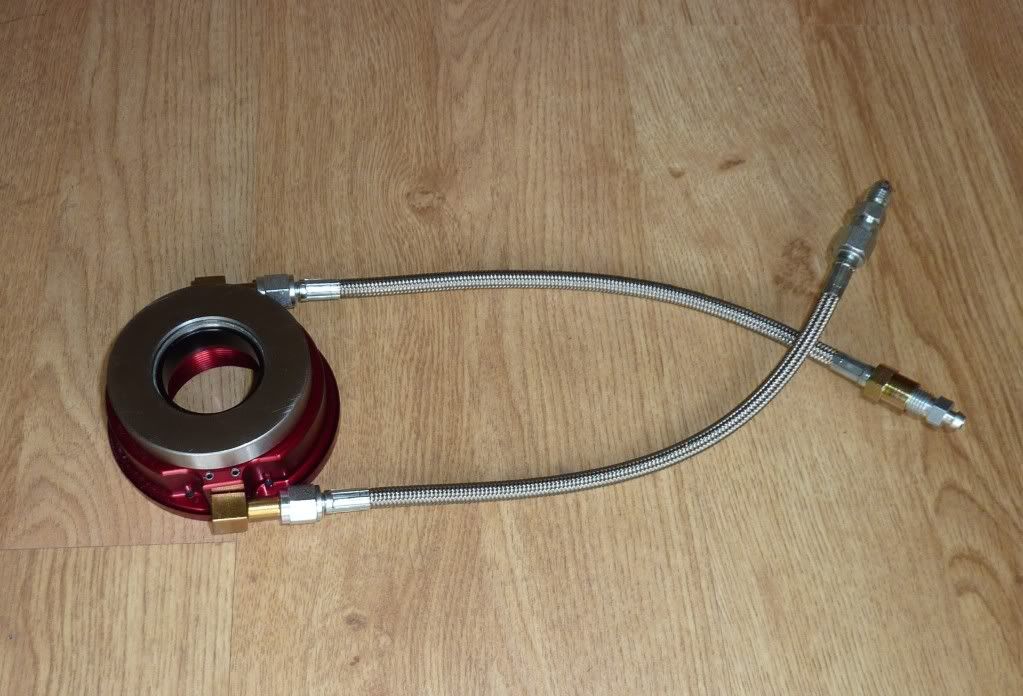

Had enough of exhausts for a while and made a start on hydraulic clutch conversion.

Slip on release bearing from Real Steel

Intructions are a bit dodgy so I googled the Mcleod part number and found loads of people complaing about leaks

Will 'phone Real Steel to check if they have had any complaints.

Posted: Sat Jun 18, 2011 6:56 pm

by sidecar

ALOT of Cobra bods have had problems with these release bearings but I've heard from somewhere or other that they've now change the material that the seal is made from so hopefully it will be OK.

Posted: Sat Sep 03, 2011 8:08 pm

by Mark

Less and less of the car left

Screen was a PITA to remove.

Front wing has been panel beaten to remove some nasty dents and marker pen on the paint is dents that need work.

Posted: Fri Nov 25, 2011 7:45 pm

by Mark

Posted: Fri Nov 25, 2011 9:06 pm

by ChrisJC

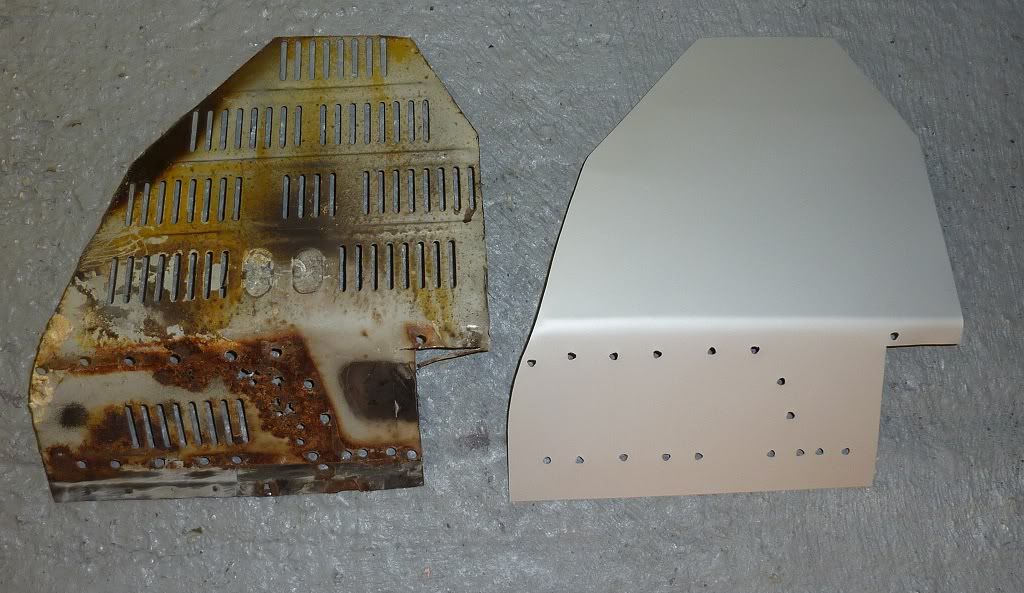

Nice!. Are you shotblasting to clean it up?, I can't quite make out how you're doing it?

Chris.

Posted: Sat Nov 26, 2011 9:58 am

by Mark

ChrisJC wrote:Nice!. Are you shotblasting to clean it up?, I can't quite make out how you're doing it?

Chris.

I shot blasted the wing repair when the weather was better and I could get the car outside as it's a very messy job, the rest was done with wire wheels and then zinc primed. (I did try one small bit with the shot blaster in the garage and it took forever to sweep all the grit up

)

cheers

Mark

Posted: Sun Nov 27, 2011 6:44 pm

by ChrisJC

Excellent. Is that a shotblasting kit?, or did you make it up?

Chris.

Posted: Mon Nov 28, 2011 10:11 pm

by Mark

It's a really basic gun I've had for years, it sucks the grit up the big pipe and the smaller black pipe goes to my 1964 Ingersol Rand compressor

Posted: Mon Nov 28, 2011 10:27 pm

by stevieturbo

I bought a little Sealey kit a few months ago, but it was rubbish.

But when I got it, it seemed like the holes in the gun that let the air through were partially blocked, and no easy way to clear them.

When air is attached, it's a pretty pathetic shot of air coming out of the gun ( no sand attached yet )

Is that normal ? How much force should the air come out with ? Would it be like a normal blow gun type attachment ?

Actual blast power from the kit was terrible. If I thought a different gun would resolve it, I'd buy one

Posted: Tue Nov 29, 2011 7:16 am

by Mark

Air comes out at full pressure, the rebound from the grit stings like crazy!

My gun is very basic with no small holes, the big pipe carrying the grit joins the air path at 90 degrees and relies on the air rushing past to suck the grit up.

The only time it gets blocked is when I've managed to sweep up a stone when recycling the grit from the driveway

Posted: Tue Nov 29, 2011 10:14 am

by stevieturbo

Sounds like my gun was just a POS then.

The drilling from air intake to trigger was quite small, maybe 5mm or so. However then next drilling from trigger up to a 090 then forward to the nozzle is very small, and IMO partially blocked. And no way to access the damn thing

I could easily hold my hand and blast the air onto it, even with sand coming through and the compressor set to 120psi.

Posted: Sat Jan 07, 2012 10:01 am

by Mark

Cleaning the underside is not a very nice job!