Page 4 of 4

Posted: Sun Sep 02, 2012 5:54 pm

by mgbv8

John Eeales will hopefully be able to sort me out with 1 or 2 new Omega pistons to replace the knackered one (s) so I can salvage parts to build another 4.6 for the Escort. He's going to check stock tomorrow and let me know. If he has any left this will means I can salvage a shed load of parts for Jasons little Escort Drag car. 7 pistons, a new blower cam, ported 4.6 heads + all the real steel 050 valve gear, a set of chevy lifters, adjustable moly push rods, all new stock rocker gear and shafts, a full ARP head stud kit, and a set of cometic mls gaskets.

I guess thats knocking on the door of a £1000 in parts for the boys track slag eh

All my Dad ever gave me was a slap now and then???

PS

New block now fitted and ready for all the bits to be bolted on

Posted: Sun Sep 02, 2012 5:56 pm

by mgbv8

Posted: Sun Sep 02, 2012 6:47 pm

by stevieturbo

Rods aside, the pistons and rings look to be in decent order. No signs of them picking up on the bores or anything.

So it's running well.

Posted: Sun Sep 02, 2012 7:05 pm

by mgbv8

Exactly Stevie!!

All rings in tip top order and still nice and free in the ring lands.

No signs of overheating on the rings or the bores.

Can you believe that this engine was still ticking over after the breakage??

And the busted piston pushed nice and smooth out of the bore. And this bore only has a few minor scuff marks that would buff out with the glazebuster ??

I'm going to take the crank to be checked as I'm pretty sure it should be ok.

If it is then I'll have a 4.6 crank + a set of 4.6 X bolted main bearing caps and cross bolts for sale on ebay

The block will be staying in my garage to join the "offerings to the God of speed" exhibition

The AFR log showed that it was still running around 11.2 and on both banks when it let go. So it just a simple rod failure I guess ??

Posted: Sun Sep 02, 2012 7:14 pm

by stevieturbo

Obviously you always want the bores to be in perfect condition, bla bla bla.

But some light damage really wont cause any major issues. Big scores wouldnt be great, but as long as there are no high spots, the bores are still round or damn close to it. I'd just hone it and use away.

It's not like it needs to last 100k etc.

Did any of the valves get damaged when the piston broke free ?

Posted: Tue Sep 04, 2012 9:56 am

by mgbv8

The block is knacked.

Apart from the holes either side I have two lifters jammed in thier holes as the rod has damaged it there, the oil suction gallery on the side of the block is punched out and at least two liners have been smashed.

I'll get some detailed pics up when I have a moment

Posted: Tue Sep 04, 2012 1:12 pm

by Darkspeed

I was talking this over with a very experienced rover man the other day and he said that at the higher RPM and power levels levels the block "pants" and a block strenthening kit is required (Girdle) - the 4 bolt mains are better but still not enough as the blocks flexe in between journals leading to failures - You need to lock it all togther.

The conversation on the block panting with Rovers came about when discussing the block strengthening kits on the little Hillman Imp engines which need a girdle when you start considering 8000 RPM+ due to block flexing.

Sorry for the little thread highjack there Pel and please do the leg work for us lazy sods and show us how to go about it all with an LS lump so we can break the Rover addiction.

ChrisJC wrote:I wonder if anybody has measured block flex at high power levels. Particularly >400BHP wot I bet Perry was running. Ultimately of course it will all bind up and catastrophically fail.........

Chris.

Posted: Tue Sep 04, 2012 8:07 pm

by mgbv8

Darkspeed wrote:I was talking this over with a very experienced rover man the other day and he said that at the higher RPM and power levels levels the block "pants" and a block strenthening kit is required (Girdle) - the 4 bolt mains are better but still not enough as the blocks flexe in between journals leading to failures - You need to lock it all togther.

The conversation on the block panting with Rovers came about when discussing the block strengthening kits on the little Hillman Imp engines which need a girdle when you start considering 8000 RPM+ due to block flexing.

Sorry for the little thread highjack there Pel and please do the leg work for us lazy sods and show us how to go about it all with an LS lump so we can break the Rover addiction.

ChrisJC wrote:I wonder if anybody has measured block flex at high power levels. Particularly >400BHP wot I bet Perry was running. Ultimately of course it will all bind up and catastrophically fail.........

Chris.

Its deffo not rpm related Andrew. mine doesnt make over 5500 on the strip unless the tyres let go. I'm now sort of wishing that this had happened on the dyno as it was due for a dyno test last week. All I know about this engine set up is that it makes 202hp on the carb and then 350hp with 7 psi of boost. We then took it to the track on several events and added boost to 12psi until it made the 10.4 seconds on the strip that it used to make with a shed load of gas. Then I added a 100 shot and hit the 10.2's. Then I stuck another 100 shot on to see if the cometic head gaskets would hold up? They held up just fine

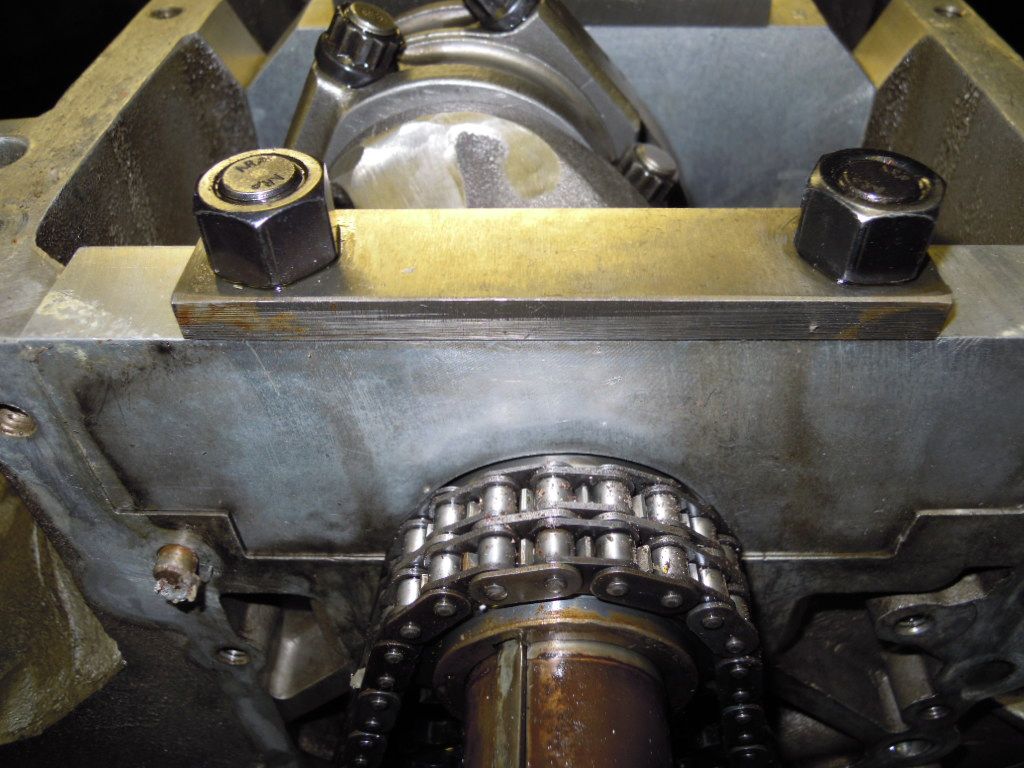

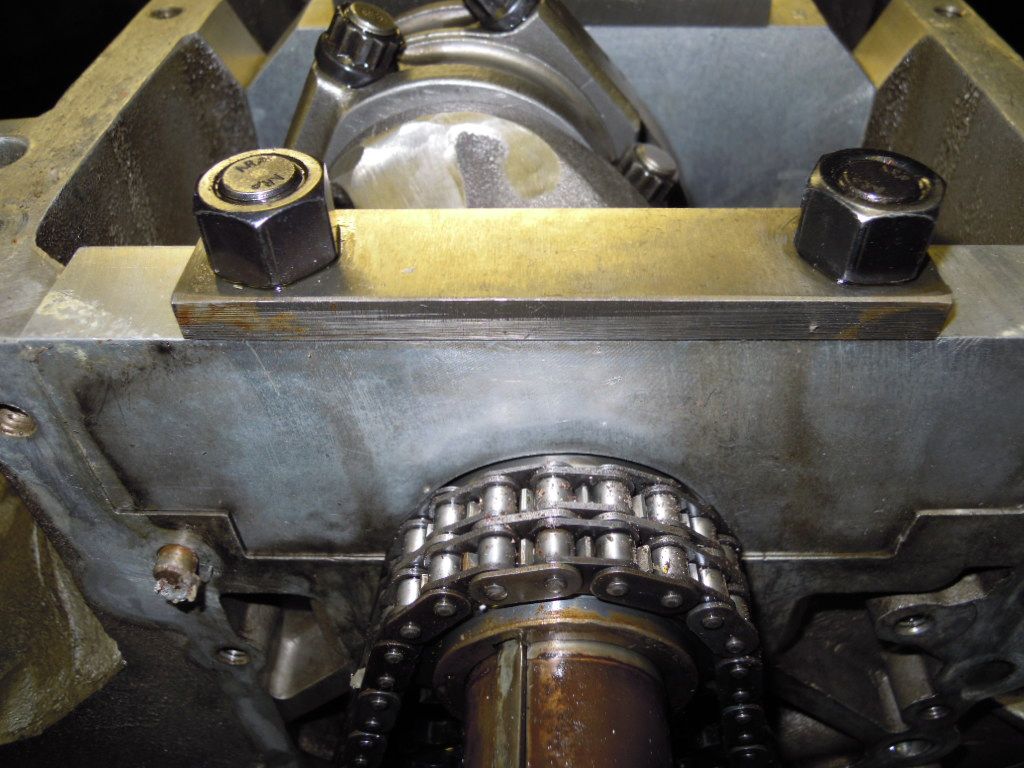

The new block has much better bearing caps made now which should assist in block strength I assume ?

Having said that. I may just make a girdle plate later in the year as I have room to fit one

Posted: Tue Sep 04, 2012 8:14 pm

by stevieturbo

Crossbolted too ?

With those studs and cross bolts, it will be a sturdy bottom end. Although some do use a simple thin girdle sandwiched in between the sump gasket and block, tying into all the main caps. Wouldnt be too hard to make really.

I'm sure Ralph85 could waterjet one out in no time and it would negate the need for those short steel plates on the main caps.

Obviously it will lower the sump by whatever thickness the girdle plate is.

Posted: Tue Sep 04, 2012 8:57 pm

by mgbv8

Yes Stevie!

Cross bolted as well. All ARP on the bottom end with Crower rods. From what I have been told this will be stronger than my stock 4.6 bottom end.?

Posted: Tue Sep 04, 2012 9:31 pm

by stevieturbo

Cant recall what size fasteners are on the 4.6 ?, but those look like 1/2" studs ? That is a lot of clamp, and the mains look well locked into the block too.

It should work well.