Page 2 of 2

Posted: Tue Nov 15, 2011 8:04 am

by ChrisJC

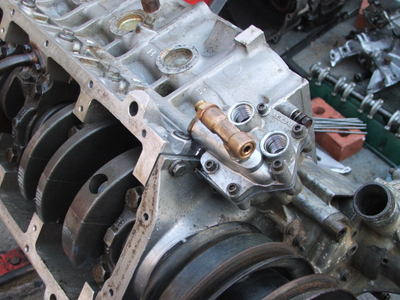

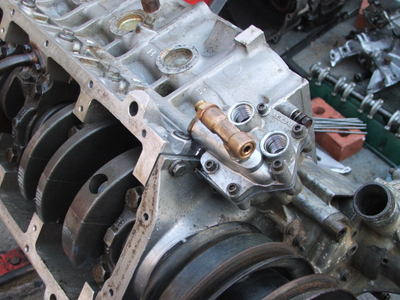

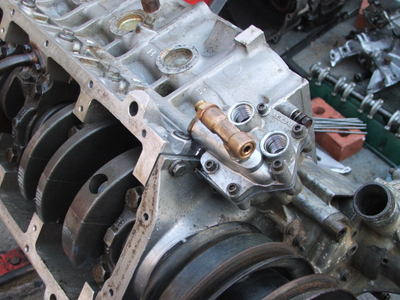

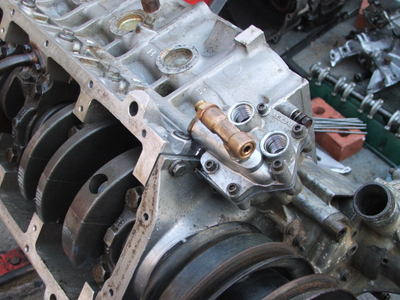

This is what I did:

Chris.

Posted: Tue Nov 15, 2011 9:41 pm

by Draughtsman

Thanks for the info Chris.

Your lucky that you have a countersunk cap head there.

Is there a different type of pump head or a sandwhich type plate?

Also, does everyone receomment that a oil pressure gauge is absolutley necessary? because I havnt got one or really got the room for one.

Cheers, Lee.

Posted: Wed Nov 16, 2011 7:52 am

by ChrisJC

I made the countersunk cap-head there. It wasn't there originally!

It's a Range Rover timing cover with the same pump cover as you have I think.

Chris.

Posted: Thu Nov 17, 2011 11:42 pm

by davemgb

Try the crossbolt without the dowty seal under the head ( the washer with the rubber liner ) just use some instant gasket instead, alternately ditch the adjustable oil pressure relief. Remember rover oil systems are about volume not pressure, high pressure just wears the pump drive gears quicker.

Dave

Oil Pump

Posted: Thu Mar 01, 2012 2:05 pm

by Draughtsman

Hi All,

Thanks for all your help, finally got around to sorting it out once & for all.

So its all done, engine put back togaether & last weekend actually managed to put engine in car.

One issue is that the oil pressure switch is now fouling the steering rack, where can I get a 90 deg. male to female elbow, is it 1/2" UNF or 1/2" NPT thread as I cant get an elbow anywheree.

Cheers, Lee

Posted: Thu Mar 01, 2012 6:25 pm

by unstable load

It's most likely BSP and your local hydraulics shoppe should be able to assist. Take the transmitter along to verify the thread.

edit to resolve brainfart....

Posted: Thu Mar 01, 2012 6:26 pm

by unstable load

It's most likely BSP and your local hydraulics shoppe should be able to assist. Take the transmitter along to verify the thread.

Posted: Thu Mar 01, 2012 7:25 pm

by DEVONMAN

1/2" UNF rings a bell with me.

Denis

Posted: Thu Mar 01, 2012 7:32 pm

by DEVONMAN

You could make an elbow from a piece of square aluminium bar by drilling through for a 1/2" bolt fixed like a banjo with 2 washers and then drill and tap at 90 degrees for the switch. There are many smaller switches out there with say a 1/8" NTP thread.

Regards Denis

Posted: Tue Mar 06, 2012 2:33 am

by gsjohnny

do you guys have oil problems with your engines? i race the 350's here in the usa and turn 7500rpm, at least i do, and have no problems with them. i even spun it at 10k(crash at the track) and all it did was beat up the bearings. all i've done is put in a bigger spring. the oil i use is plain ol' valvoline 10-30.

john

Posted: Tue Mar 06, 2012 7:20 pm

by teamidris

Why not put the pressure switch in the remote filter housing?

Do we have problems with RV8 oil pressure

Ooooh yes!

Too much or too little and the hydraulic tappits get grumpy. And the old RV8 pump is more of an impeller than gear pump? It has a lot of end float.