Hi All

I have managed to get some time out in the garage this week and whilst progress has been made things did not work out quite as expected.

Having released the lower section and given that a sand down on 120 and then 400 grit paper it was obvious that I needed to do a few small repairs to make everything as it should be before final finishing on 1200.

I turned my workshop and works van upside down looking for the orange pigment to the point that I thought I was losing the plot as I knew that I had some but could not find it anywhere.

So that part of the project had to go on hold so attention was turned to the upper main section.

Out with the stanley blade pin hammer and a load of spreaders I set to in releasing.

Initially things where going well as the plug could be heard as usual popping and cracking as it released but then it stopped moving up out of the mould which had me scratching my head for a moment as I could not work out what was stopping it.

Ah ha cut out the glass from the top filter rebate you FOOL

Air hack saw in hand I soon made mincemeat of that little lot and this was what was left.

A point of note here it that this area of glass was always to be cut out as it does nothing for the mould at all.

Then it was back to the spreaders and hammer plus a lot of patience as after all of the work that has gone into this i did not want to mess things up now.

Slowly and surely the plug came away from the mould but it was taking damage as it (the plug )was only made from foam some filler and a skim of gel so in real terms damage was inevitable.

The last bit of releasing was a bitch and in all honesty I was maybe a little too sure of how it was going to release once I got to this stage.

What I had missed when prepping the mould all those post ago was a very small lip right at the base of the top filter rebate and this was locking the thing in so tight it just did not want to move.

I only found this out after some severe carnage to the plug which I had hoped to show released and all but intact but the humble pie gods had other plans for me last night!

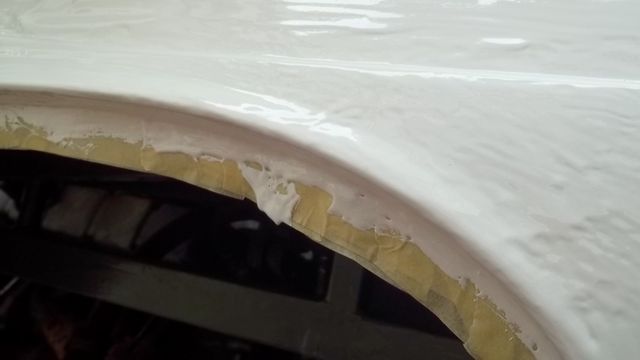

With everything finally released I could see immediately that there was a small amount of damage to the mould but this is very simple to repair and I will show how this is done maybe a little later on today.

I also need to get rid of the little lip /defect at the bottom and then sand the whole lot down going through the grades and then a good polish up so I can make the real thing.

As the final unit will be just a shell releasing of the upper section will be much easier to do he said hopefully.

With the two sections together you can see that I will have a large internal area for the carb to draw from and with luck it will work out fine .

You can also see that I do need to do a little bit of final finishing around the filter rebate but this is just a few minutes work.

Oh and the orange gel pigment that I went mad looking for?

Yeah my son had it in his van but never told me he had took it from the garage.

What a bizzare way of handing your notice in........

Anon