Page 8 of 9

Posted: Wed Aug 08, 2007 8:56 am

by kev_the_mole

Now I've got the bug perhaps the estimable Mr. Cooper could arrange a V8 Forum Track Day and we could all see each other's cars performing (but only after I've fixed mine!

)

Cheers,

Ian

Posted: Wed Aug 08, 2007 8:57 am

by ChrisJC

I think it's pretty brave to take a new car on the track without some testing first!

Everything I've done has had some wrinkles to iron out. Even the big manufacturers make a whole batch of cars to sort out the wrinkles!

Chris.

Posted: Wed Aug 08, 2007 9:03 am

by kev_the_mole

I think it's pretty brave to take a new car on the track without some testing first!

We tried it round the industrial estate first (not on the road, honest guv'nor).

....but I did wonder why none of the others there that day wanted to give it a gentle run

Posted: Wed Aug 15, 2007 9:10 am

by kev_the_mole

Wooo Hooo

passed its MOT yesterday with flying colours including the slightly suspect, devious electronic line-lock 'parking brake'

....then it boiled over coming back from the test centre so maybe the problem wasn't lack of an expansion tank

Is God telling me something???

Posted: Sun Jan 06, 2008 7:56 pm

by kev_the_mole

Sitting in traffic or just leaving the car idling in the drive while opening the garage door and the temperature shoots up. The poor little 14" fan struggles to cope when the air temperature goes over 18C.

Weeny fan

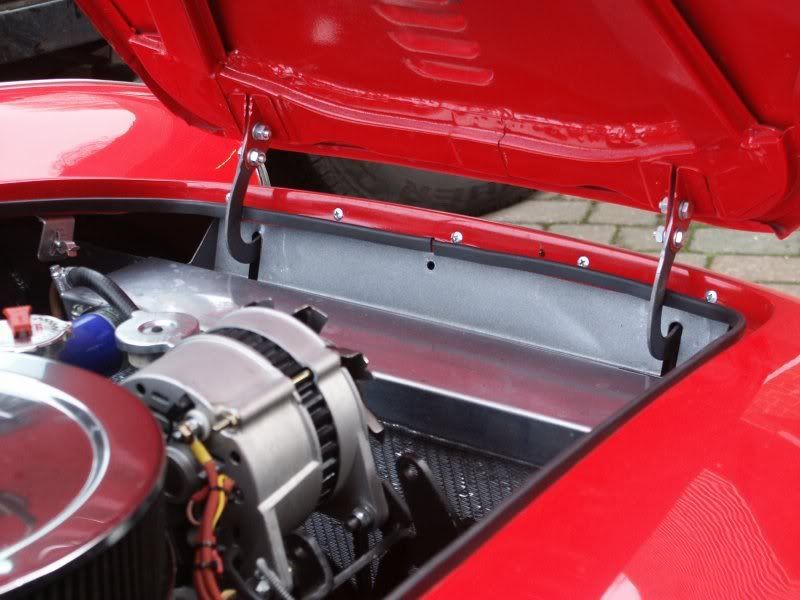

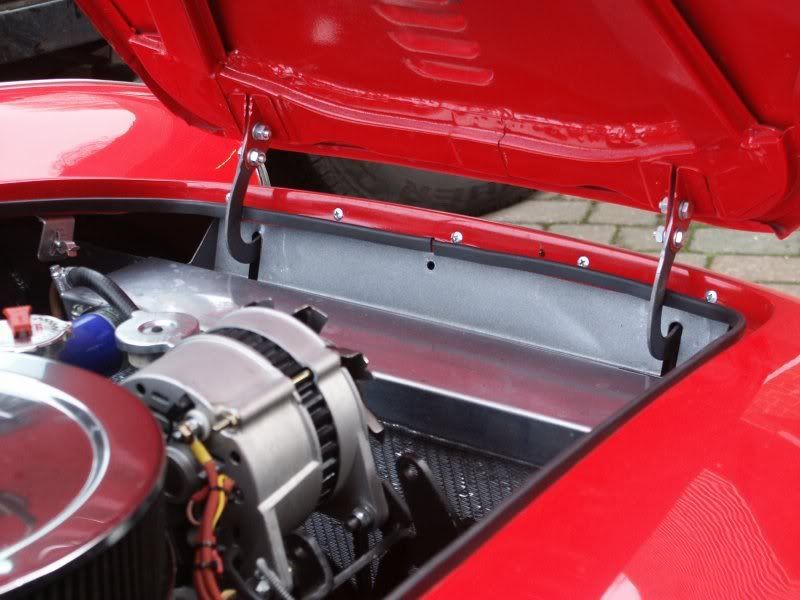

This shouldn't happen with a Serck Motorsport radiator but I did compromise the design by insisting on keeping the bonnet hinges and that made the radiator smaller than first anticipated.

Short radiator due to retaining bonnet hinges

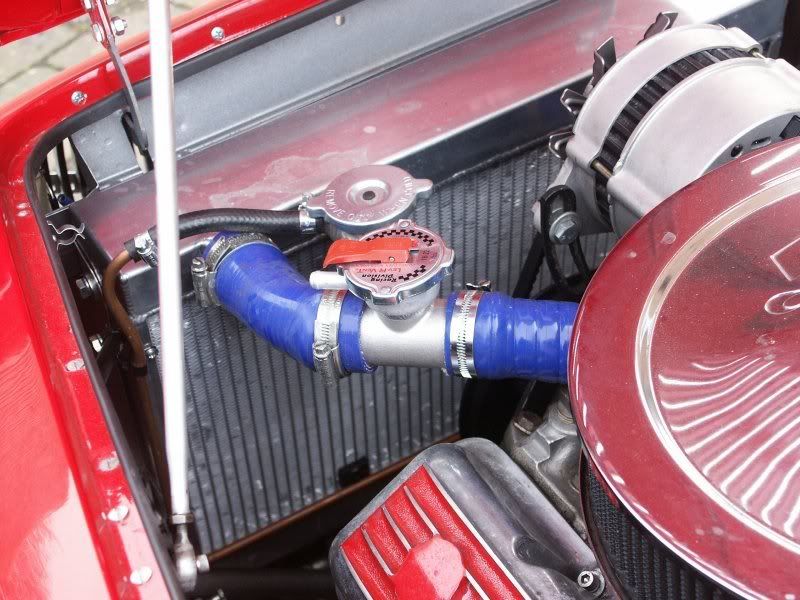

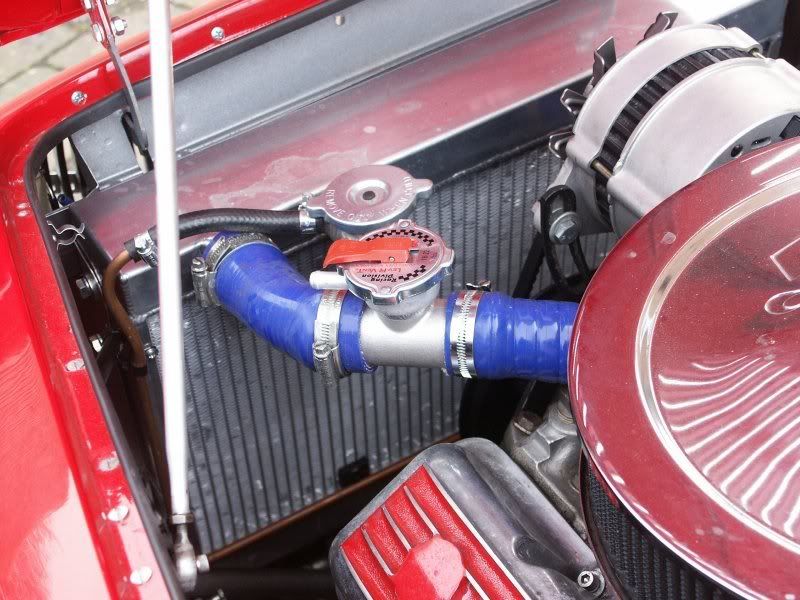

Another cooling problem was that after a few circuits on a trackday the car would be dumping water and it looked like we had a recurring air lock. Because the radiator was relatively low it meant the top hose was higher than the radiator filler. To cure this problem I fitted a Moroso top hose filler neck and fingers crossed it looks like the air lock has disappeared. I also decided to use a Stant radiator cap with a flip over valve to release the pressure safely if I get further problems.

Moroso top hose filler

In the spring the radiator comes out to have its filler neck modified and I'll tidy up the hoses then. Also I'll add another 14" fan so they run side-by-side and should provide enough low speed and warm weather cooling.

Posted: Tue Mar 11, 2008 5:39 am

by kev_the_mole

Posted: Sun Mar 16, 2008 12:36 pm

by kev_the_mole

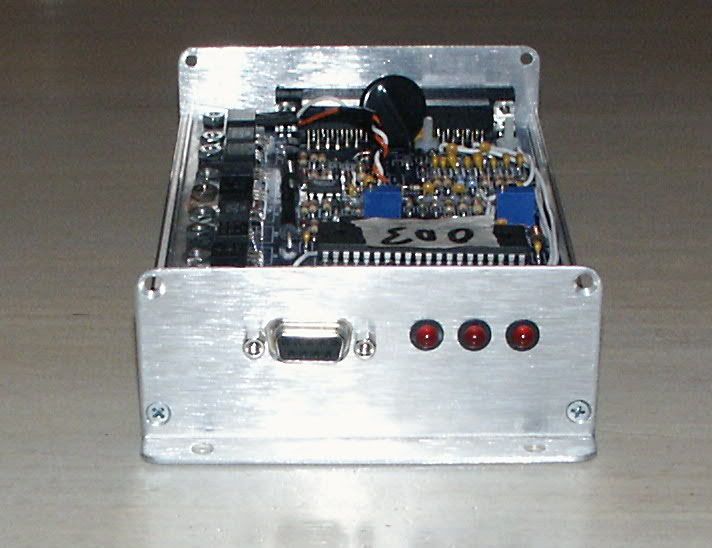

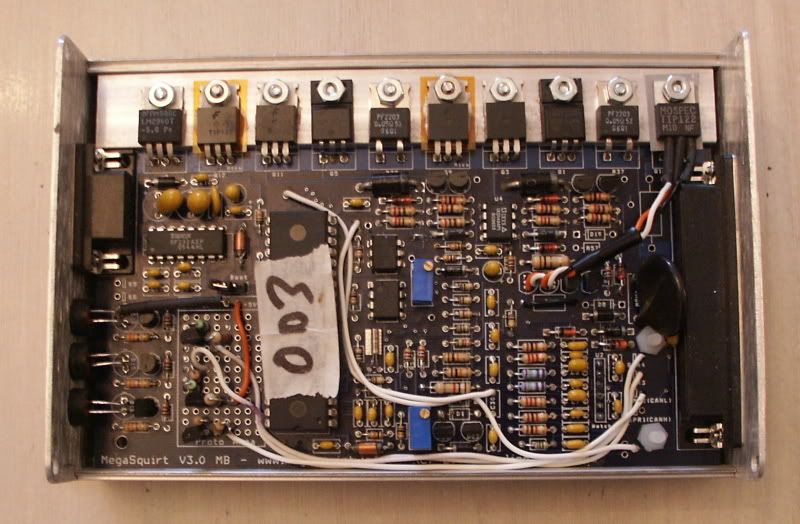

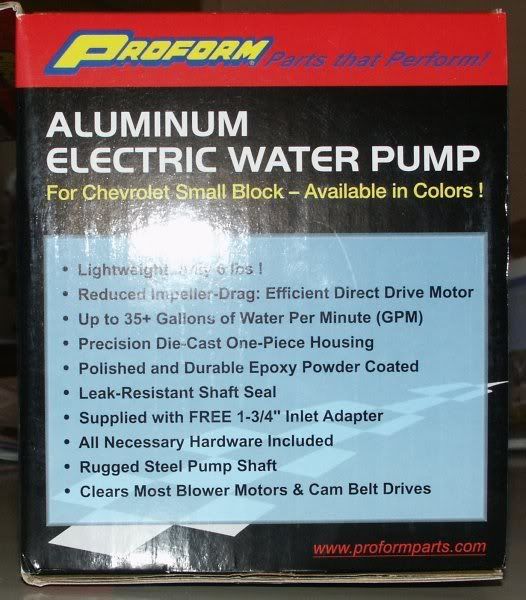

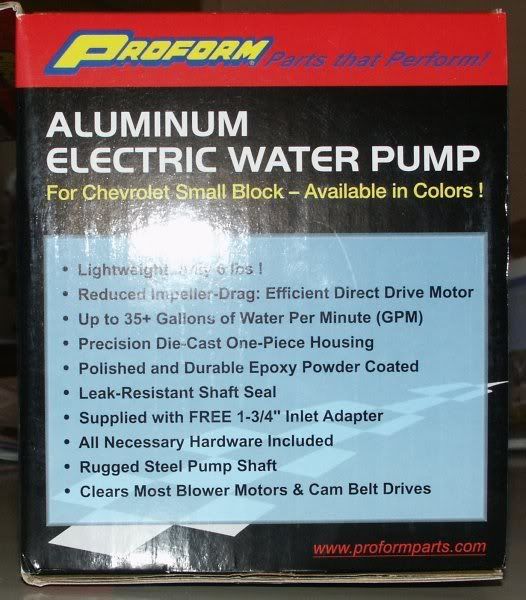

Decided to do something about the cooling at the same time as all the other work so with a tiny engine bay and the old Healey problem of hot air sat trapped under the bonnet I reckon that I need a bit of post-engine switch-off cooling. I wasn't going to do it with a mechanical pump so Mr. Summit delivered this nice and cheaply last week.

and then I though maybe a fill of this stuff which due to its low expansion and high boiling point turns the cooling system into a very low pressure system which should help to protect the seals on the Procomp pump.

EVANS NPG+ Coolant is a blend of glycols with particular additives that do not require water to remain in solution. As it remains substantially vapor free in the coolant jacket, liquid-to-metal contact is maintained regardless of coolant temperature or engine load. By bathing the entire coolant jacket with vapor-less coolant 100% of the time, metal temperatures are controlled to such an extent that critical levels of detonation and pre-ignition are never reached. Because EVANS NPG+ boils at 375 degrees F, the need for high pressure in the cooling system is eliminated. The only pressure generated in an NPG+ cooling system is due to the expansion of liquid, never by the formation of vapor. Consequently the build-up of pressure in a system using NPG+ is typically in the range of just 2 to 7 psig and gasket seals, hose connections, and even the radiator core, are under less stress and operate safer and longer.

http://www.evanscooling.com/main25.htm

Now all I need is a timer to give me a short delay after starting and a longer delay after switch-off for the pump and fans. Any ideas?

Ian

Posted: Wed Apr 30, 2008 9:42 pm

by kev_the_mole

Posted: Fri Feb 27, 2009 9:30 pm

by kev_the_mole

Thought it was about time for an update. Lost the plot last year after blowing up engine at Castle Combe. Then the crate engine replacement had problems and then my younger son was assaulted and in a coma for two weeks but now it's nearly spring and warm enough to work in the garage.

Here's the engine still in the crate

and out of it's crate with the 'lectric water pump

Posted: Fri Feb 27, 2009 9:43 pm

by kev_the_mole

This is day two of the interminable fitting a quart into a pint pot.

Somewhat akin to an automotive hokey-cokey!

'You put the engine in'

'You take the engine out'

'In - out, in -out'

'Shake it all about'

'You do the hokey-cokey and

you go down the pub forlorn of all hope'

I think the rhyme needs a little work on it but I feel it sums up the magnitude of the task

I suppose I could submit it for publication in the

"Little Goth and EMO Book of Children's Rhymes of Despair"

As the HEI dizzy was bigger than the old one the consensus of opinion was that the bulkhead needed to be moved back 35mm. One suggestion was that it should opened up and then boxed back however we cleverly mounted most of the electrics behind it on a previous incarnation. Or my best idea was that I took a 12lb sledge and make it fit

In the fullness of time reason did prevail.

For future EFI a crank trigger was fitted.

Posted: Fri Feb 27, 2009 9:58 pm

by kev_the_mole

SOD SOD SOD

After the tin snips came out and the firewall was cut and boxed back.

The new air cleaner and inlet manifold are too tall.

This means that we either have to put the old stuff back and choke the engine (not gonna happen

) or my pristine and lovingly restored louvered bonnet is going to have to go and I will have to have a new one with a 'hood scoop' to manage the clearances.

Bugger!

Et voila! Les tin snips came in handy again. I am now officially in the V8 Forum 'biggest hole in bonnet' competition then

Posted: Fri Feb 27, 2009 10:05 pm

by kev_the_mole

Posted: Sat Feb 28, 2009 10:53 pm

by kev_the_mole

....and then we started it up

....it was apparent that it was rougher than a badger's backside.

The next morning it was discovered with a puddle of water below the exhaust. Pete suspected either inlet manifold or head gasket but after the inlet manifold gasket was found to be blameless the head was pulled and it was obvious that water was getting in from the inlet side.

The view down the bores

The cylinder head

The culprit!

Posted: Sun Mar 01, 2009 8:22 am

by Mark

That has to be soul destroying

I hope you get it sorted out OK

Mark

Posted: Sun Mar 01, 2009 11:17 am

by CastleMGBV8

Ian,

Sorry to hear of your problems, not sure of the relevance of the ex. port picture, i seem to remember you had a problem with a previous head that had been over ported, is that what your indicating is the same problem or is it purely a gasket sealing problem.

I'm no expert on Chevy engines but it looks as if the head/s were not seating correctly and allowing proper compression of the gaskets but I could be completely wrong.

You appear to be using head bolts, any chance they are bottoming out before correct compression of the gaskets ?

Kevin.

)

)