Evening guys

Here we go then with the cradle section.

The main section was roughly trimmed down with the air hacksaw for two reasons.

1 Getting glass splinters in your mitts is not so good and unless you get them out right away they casn work their way in and stay there for good.

I have splinters in my fingers that have been there nearly 30 yrs.

2 When I'm working I try to keep my station as clean as possible as this for some strange reason just 'feels better'.(Yeah I know WEIRDO)

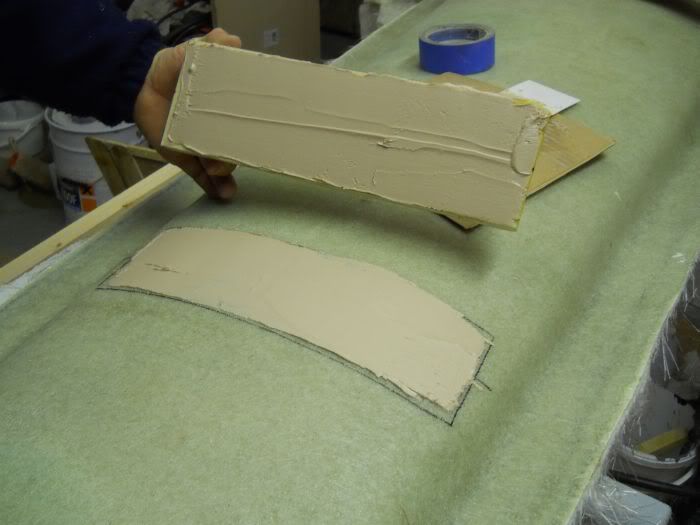

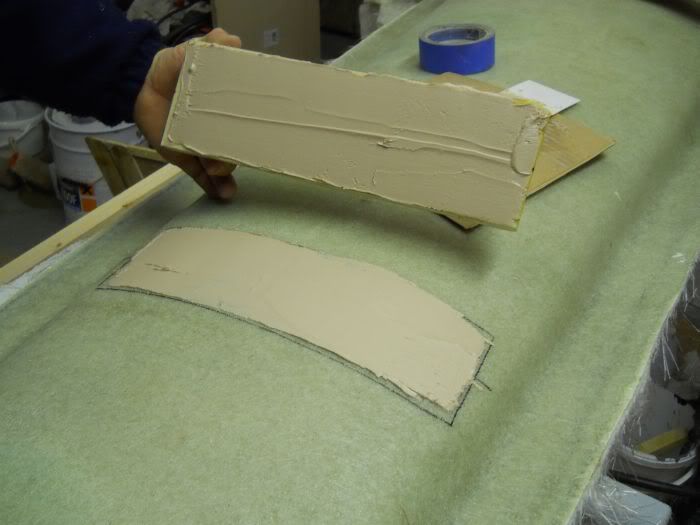

With the mould trimmed down it was time to break out the 1" thick bracing foam and cut that to size.

The foam is fairly rigid but with a bit of persuasion it will bend.

With measurements of 20" from each end of the flanges the areas were marked out on the laminates and then skimmed with car body filler and plonked into place.

They were then held in position with pig blocks (or kin heavy weights with handles on them)

It should be noted that the CAVE TROLL hands belong to my very good friend John who came down to help for the evening.

Brilliant craftsman but absolutely crap when trying to weld stainless steel,another story another time that one eh John

A good point to note at this stage is that all Polyester resins and fillers go through a stage of exothermation which means that they generate heat as they cure and then as it cures it shrinks back causing an almost vacum like situation which then transfers to the mould itself and with something like this it is much better to do a slow/minimum hardener mix which allows for curing without pulling the underlying substrates away from the plug.

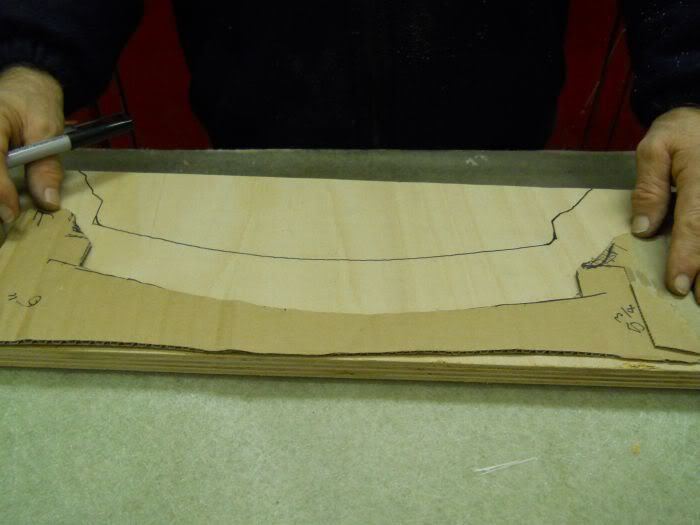

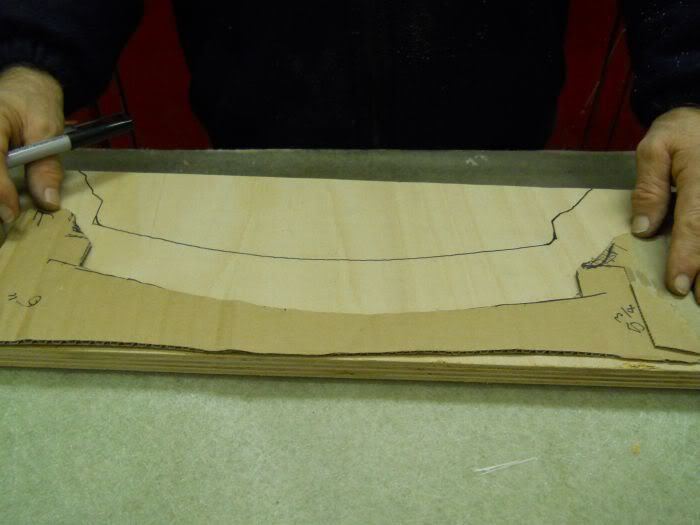

As the filler cured on the second brace we cut some cardboard and scribed the shape of the first brace to transfer to wood once we were happy.

And then cut to fit and coved in with filler.

The same was done on the other brace and we ended up with this.

The corners were then cut to the shape of the timbers being used for the base lengths.

The base lenghts were then screwed onto position, trimmed and that was that, cradle completed.

You might wonder why the cradle has not been glassed in yet and the answer is simple.

The temperature has to be fairly stable whilst the resin is curing (anything above 10 degrees c is fine)

The last 2 evenings have seen the temperature fall very quickly and whilst it is okay to have a heater in the workshop you will have to switch it off when you finish for the night.

The temperature will then obviously drop and this will cause an uneven cure rate which could and often does lead to crap results.

Glassing will take place tomorrow during the day.

Ok all thats it for tonight.

cheers

P

Mike you should be able to get acetone from all grp suppliers.

It is often known as brush cleaner and sold as such.

I buy it in 5 gallon kegs but could if I wanted have a 40 gallon barrel of it at home

Do you want me to get you some for when you come down?

but if I can or you need help I will do my best.

but if I can or you need help I will do my best.