Page 10 of 13

Posted: Tue Jun 28, 2016 8:51 pm

by Mark

gelmonkey wrote:You drew that

How the hell do you do that?

Car is looking awesome Mark you gotta be pleased.

Using the lounge as a workshop pretty cool too although not sure that Mrs G would be happy for me to use our lounge for car stuff

Keep up the good work

P

Took me a long while using a 3D cad program, that is the 4th attempt I think

Had to hoover the lounge after I had finished !

Not allowed to keep motorbike in there over the winter though

Posted: Tue Jun 28, 2016 9:48 pm

by gelmonkey

Impressive mate

Can just about turn my computer on let alone do a drawing on it

Cad design is very very cool but way beyond me

Excellent stuff

P

Posted: Wed Jun 29, 2016 3:24 pm

by v8trev

The standard of your work is truly inspiring

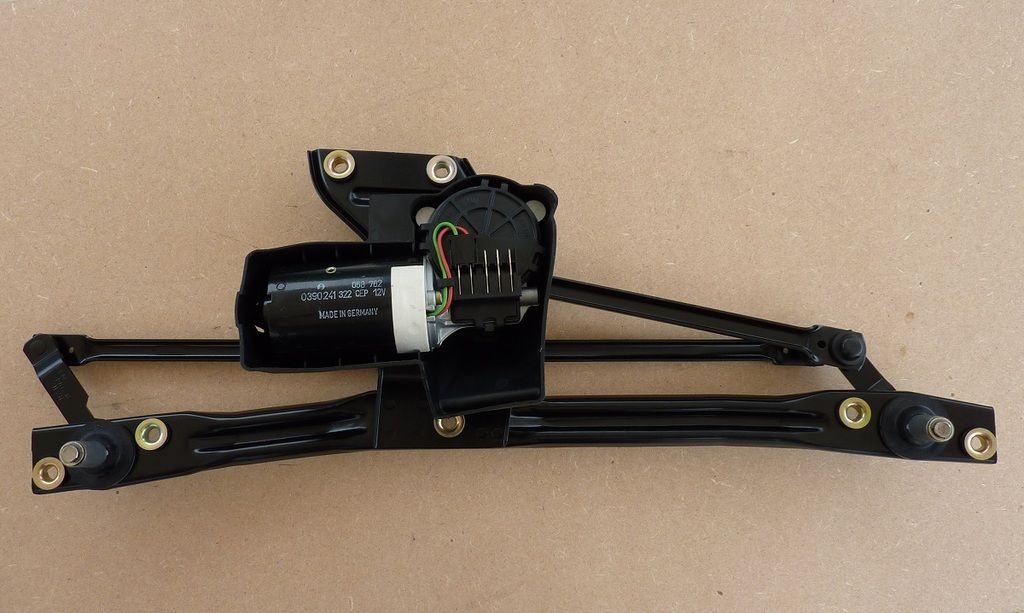

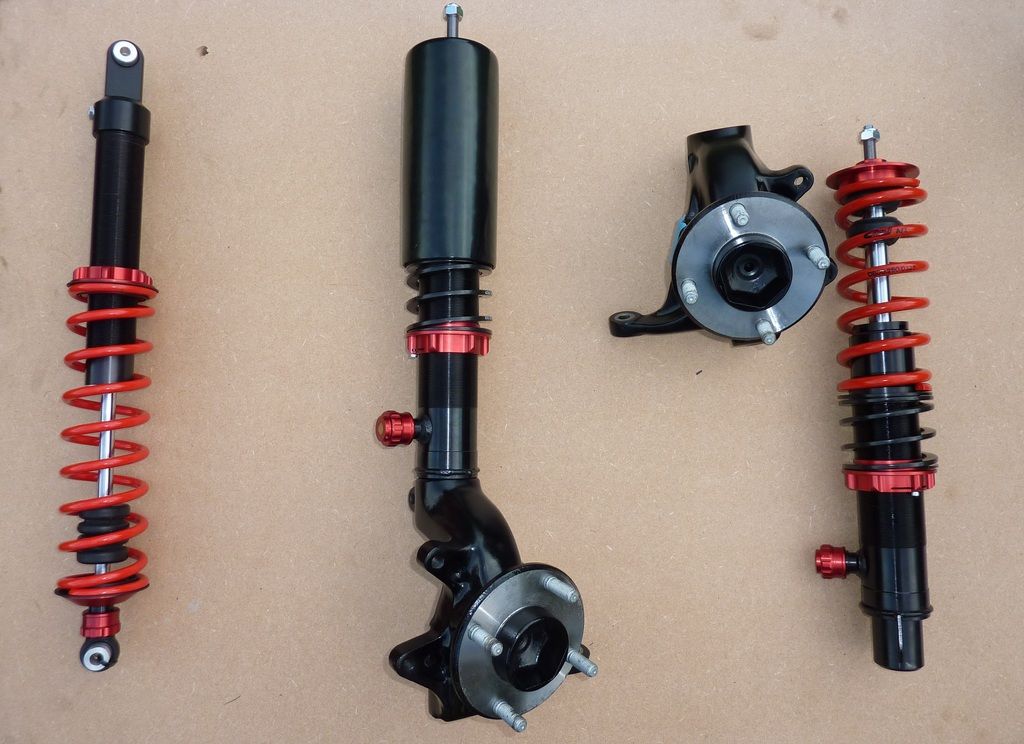

Posted: Sat Sep 17, 2016 6:03 pm

by Mark

Posted: Sat Sep 17, 2016 6:40 pm

by stevieturbo

Impressive !

Posted: Sat Sep 17, 2016 7:06 pm

by gelmonkey

PORN PORN PORN and more porn

Awesome work mate you going to bring it to the Retro show next year ?

Fantastic

Cheers

P

Posted: Sat Sep 17, 2016 8:13 pm

by Mark

gelmonkey wrote:PORN PORN PORN and more porn

Awesome work mate you going to bring it to the Retro show next year ?

Fantastic

Cheers

P

Don't think I'll have the time or money to have it done for next year

Posted: Sun Oct 16, 2016 8:31 pm

by Mark

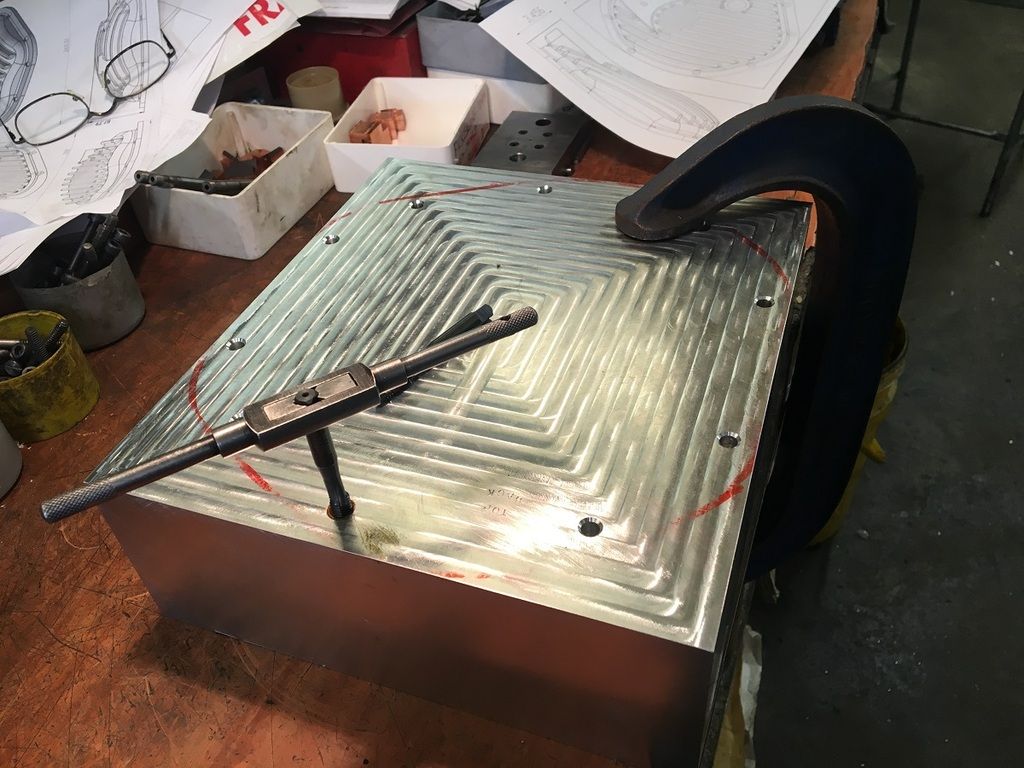

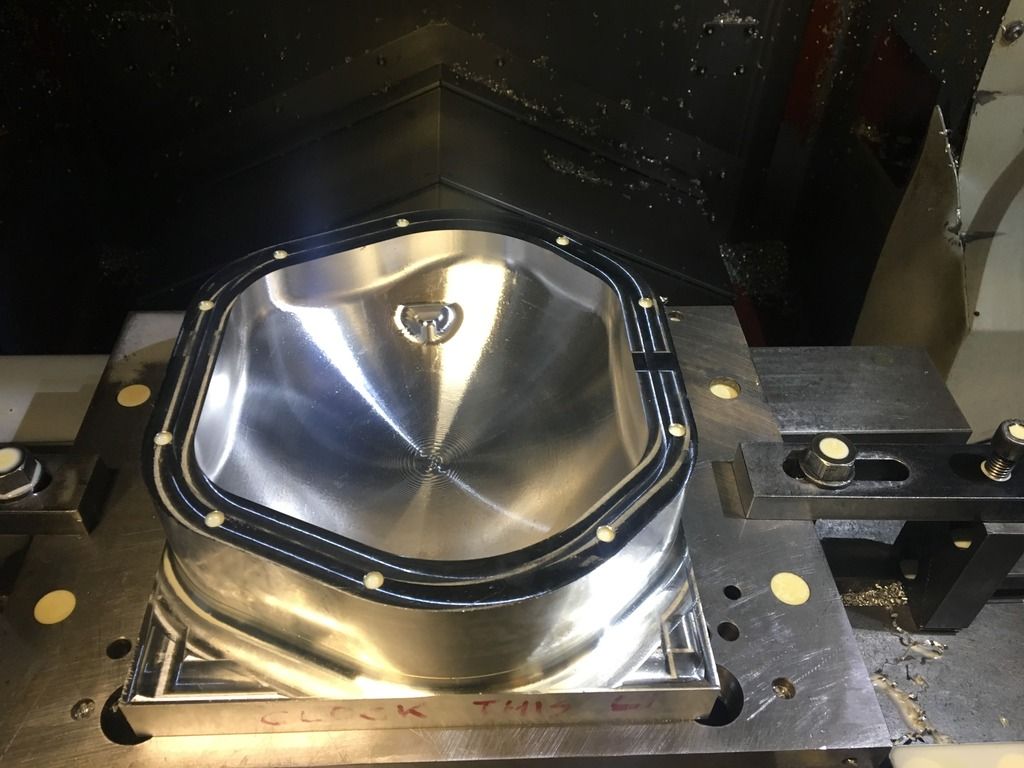

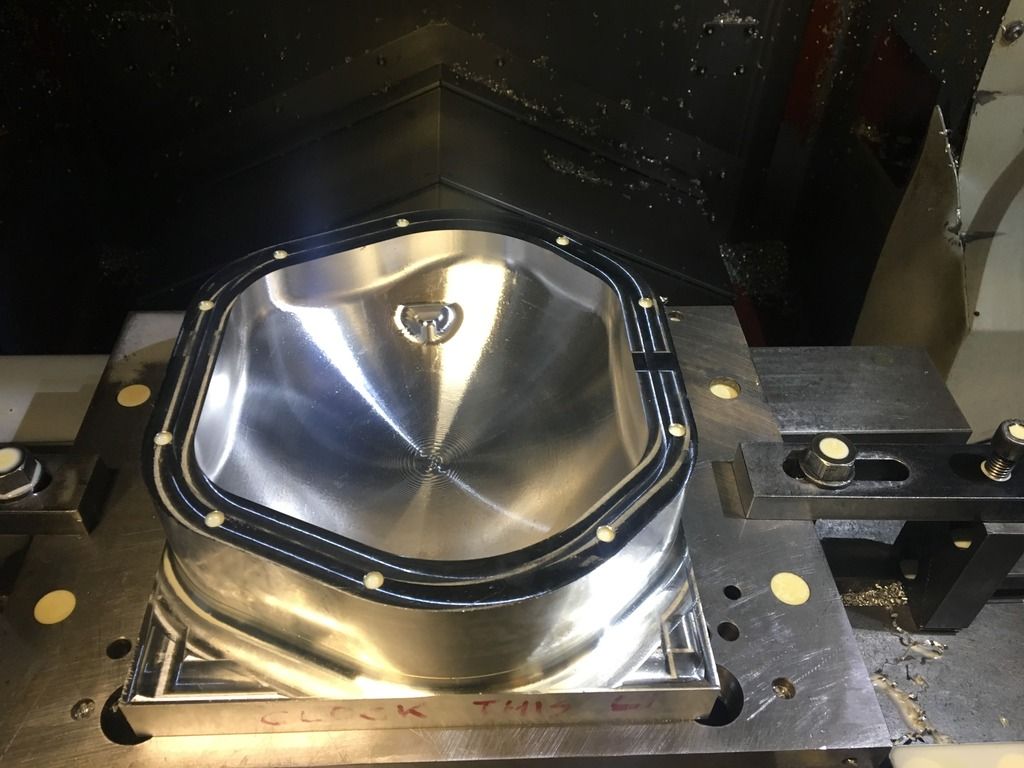

Some progress on diff cover

I've been trying to learn some 3d tool path software and had some luck.

http://img.photobucket.com/albums/0703/ ... scbkbe.mp4

The outside with the fins is proving far more difficult and I'm stuck at the moment !

Posted: Sun Oct 16, 2016 8:49 pm

by Coops

Looking awesome mate well done

Posted: Sun Oct 16, 2016 9:04 pm

by stevieturbo

I suppose grinding them out with an angle grinder would be out of the question ? lol

Posted: Mon Oct 17, 2016 6:19 pm

by Mark

stevieturbo wrote:I suppose grinding them out with an angle grinder would be out of the question ? lol

It would need a lot of Solvol Autosol to make it shiny afterwards !

Posted: Mon Oct 17, 2016 7:50 pm

by stevieturbo

TCT blade in a grinder ? lol

If the fins are just straight, some sort of mill could machine them out ?

Posted: Tue Oct 18, 2016 8:42 pm

by Mark

stevieturbo wrote:TCT blade in a grinder ? lol

If the fins are just straight, some sort of mill could machine them out ?

The fins follow the curve of the bowl in the cover, the machine I've been using is a type of mill - just has a posh name "CNC machining centre"

I'm a novice with the software, that's the main problem

Posted: Tue Oct 18, 2016 9:00 pm

by seight

Love it, keep em coming.

Posted: Tue Oct 18, 2016 10:12 pm

by stevieturbo

Ahh right, get ya now, thought ya just meant the exterior fins which would finish sort of straight.

But yea they would contour at the bottom.

Although you managed to get the internal surface curved ?