Page 2 of 2

Posted: Fri Aug 23, 2013 10:15 am

by chodjinn

scudderfish wrote:If you ever find yourself saying "it'll be ready for Christmas", just mentally note to yourself that you're not saying which one.

Haha I already had!

Posted: Sat Aug 24, 2013 8:53 am

by unstable load

Personally, I prefer "It'll be ready on the 1st."

The First Oppoertunity......

Posted: Thu Sep 05, 2013 10:36 am

by chodjinn

Well I tack welded my first repair panel in last night, and if I'm honest I'm pretty happy with it! No pics as I was way too excited and went and got drunk straight after lol. As I haven't bought sheet metal for the rear arches yet, or bars to brace the doors with so I can start the sills, the only real bit I could do was the front inner arches at the top of the footwell.

So last weekend I chopped out the arch reinforcement part and all the rot to match the repair panel. Last night I gave the welding a go. It was an absolute barsteward as the repair panel was arched at the bottom, but I use a huge c-clamp and some 3mm aluminium to help bring the panel into line as I went along tacking it.

Planning on doing more tonight and over the weekend so i'll take some pics then.

Posted: Thu Sep 05, 2013 7:05 pm

by kiwicar

Hi

I think you may have been bitten by the bodywork repair bug, fortunately you have an MGB so there will be plenty for you to repair. I suspect you are in for a happy autumn of cutting custom forming and stitch welding

I am sure you will love it. Personally. . . . it is not my thing . . . . have lots of fun

best regards

Mike

PS there are some very good articles on the Carcraft.com website on all things body repair

Posted: Fri Sep 06, 2013 8:00 am

by chodjinn

Well I welded the repair panel up fully last night, and it came out great! I sanded the inner wing back and along one side you can't even tell it's been welded, whoop! Definitely bitten by the welding bug now, this weekend is gonna be fun!

Posted: Fri Sep 06, 2013 10:20 am

by kiwicar

Hi Chodjin

A mate of mine got bitten by the "Bug" he bought the remains of Syd James' porsche 956 that had sat out side for 18 years under a tarpaulin. He decided to rebiuild it without any reproduction panels, just hand formed steel and any year correct panels he could find. After a while he decided it should be a "custom" restoration as he could not find a year correct engine for it so he put in a 911 turbo unit and suspension and box. he then modified the rear bodywork to cover the slightly bigger wheels. The result was stunning but the amount of work was mad, he now runs a business building custon VW busses and steel bodied 956 replicas based on beetle floor pans, boy he has it bad!

Best regards

Mike

Posted: Fri Sep 06, 2013 11:48 am

by chodjinn

kiwicar wrote:Hi Chodjin

A mate of mine got bitten by the "Bug" he bought the remains of Syd James' porsche 956 that had sat out side for 18 years under a tarpaulin. He decided to rebiuild it without any reproduction panels, just hand formed steel and any year correct panels he could find. After a while he decided it should be a "custom" restoration as he could not find a year correct engine for it so he put in a 911 turbo unit and suspension and box. he then modified the rear bodywork to cover the slightly bigger wheels. The result was stunning but the amount of work was mad, he now runs a business building custon VW busses and steel bodied 956 replicas based on beetle floor pans, boy he has it bad!

Best regards

Mike

Sounds like my dream job!! If I could get paid well enough for restoring motors I would have done it years ago.

Posted: Fri Sep 06, 2013 12:49 pm

by kiwicar

Hi

If you get good at body work I think there is good money in it, the first thing though is to enjoy it, the second is to practice. My mate with the porsche ( 356 not 956, the 956 is a big GT car thing) did a whole series of courses and evening classes and read everything he could, he thoroughly enjoyed it but I think it is something you have to love, the money is in the detail of restoring panels that should be binned just so it is "original"

Best regards

Mike

Posted: Sun Sep 08, 2013 5:53 pm

by chodjinn

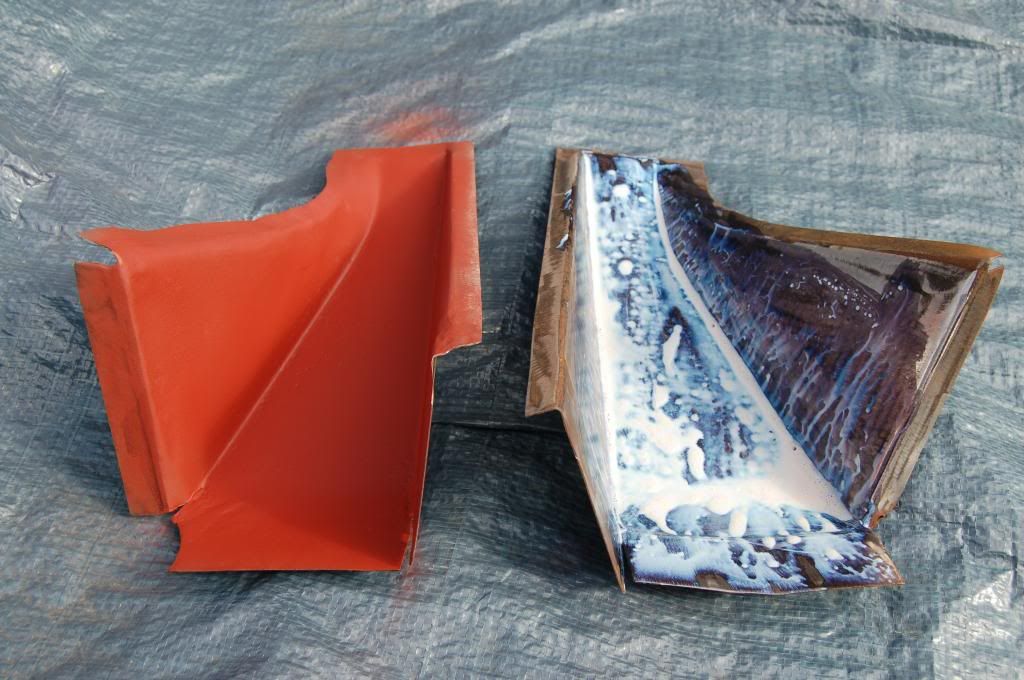

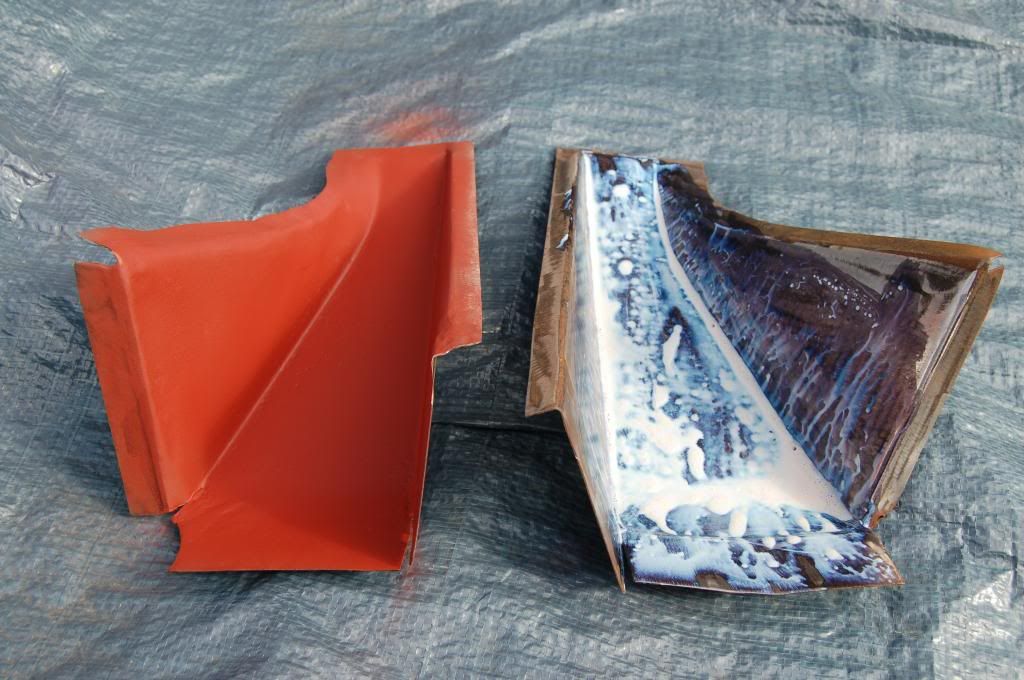

Some pics of my first welding attempts. Replaced both the upper inner wing sections at the front. Both the arch reinforcements had rusted & been repaired previously but it was done badly and had rusted worse. Got the arches both welded up ok but ran out of wire as I was nearly finished on the passenger side, so have spent the rest of the weekend shaping the arch reinforcements as they were all over the place and needed a bit of resto work themselves (even tho they were 'new old stock' they were covered in rust). Haven't taken pics of the passenger side yet as not finished, and need a lot more sanding etc. both sides.

Passenger side cut out;

Drivers side welded;

Prepping the arch reinforcements;

Posted: Wed Sep 11, 2013 8:30 am

by chodjinn

Got an offer I couldn't really refuse from Rallysport for a complete Cosworth fuel system, so having not really spent much on the MG for a good while other than panels, I bit their arm off lol. This should do the trick for the planned 1uzfe (which I'm now getting worried about actually fitting in the engine bay!). Included a brand new fuel cell & Sytec pump not in pic. I just need a Y-block for the fuel rails and a decent FPR and the whole system is complete

Posted: Thu Dec 12, 2013 12:28 pm

by chodjinn

Not been doing much on the car for the past few months due to work committments. Most of the fuel system I bought (previous post) is going in the Skyline as it'll jut bolt straight in, and I didn't want to chop about the MGB shell any further, with potential MOT issues with an internal fuel tank. Saw this the other day, just won it for a bargain;

http://www.ebay.co.uk/itm/400620409994? ... 327wt_1146

Very nice. Means I can keep the tank external, use the existing filler cap and sender unit I have. Also use one of the EFI pumps I already have, so pretty much sorted for fuelling for the MG now. Just have some straps to make for it.

Few weeks ago I also bought a Lincoln Electric MIG welder, so my plans over xmas are to get support bars welded to the bodyshell and chop off the sills and floorplans ready for new year weld-a-thon!

Other progress has been made on the suspension side of things. I've spoken to Fab-Tek in the States who are making me some 1" drop spindles, axel location bracket (symmetrical, so hopefully better than a Panhard rod) and some adjutable axel lowering blocks. I'll be seriously considering the Moss coilover kit (altho a friend has just made his own for less than £300!), negative castor lower arms & adjustable front anti-roll bar. I'm not planning on fitting one to the rear to keep it fun haha.

That's it for now, hopefully have update pics in the new year after some chopping.

Posted: Thu Apr 03, 2014 7:13 am

by chodjinn

Righto, this one has been canned unfortunately. Mainly for financial reasons but also because I can't face all the welding at the moment. I'm 34 and I want a car to drive, not spend half a decade restoring! Shell has been sold to a fella who works with adults with learning difficulties and he's picking it up saturday. Sold all the repair panels and a bunch of other stuff, for a decent profit I might add. Spent that already!

The rest of the parts such as racing bodykit, interior, axels/hubs/brakes and other parts etc. will all be put into storage for use on a future 'B project. All the fancy engine bits I have accumulated over the years will be put to good use very shortly. Watch this space ...