ot but hits chassis

ot but hits chassisFitting

Moderator: phpBB2 - Administrators

Fitting

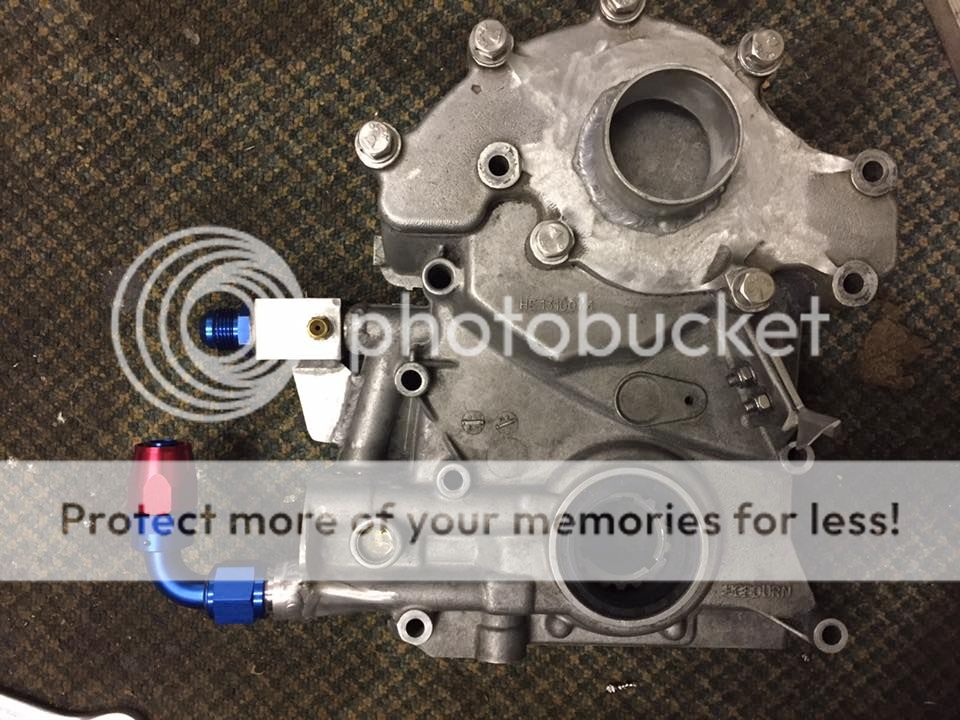

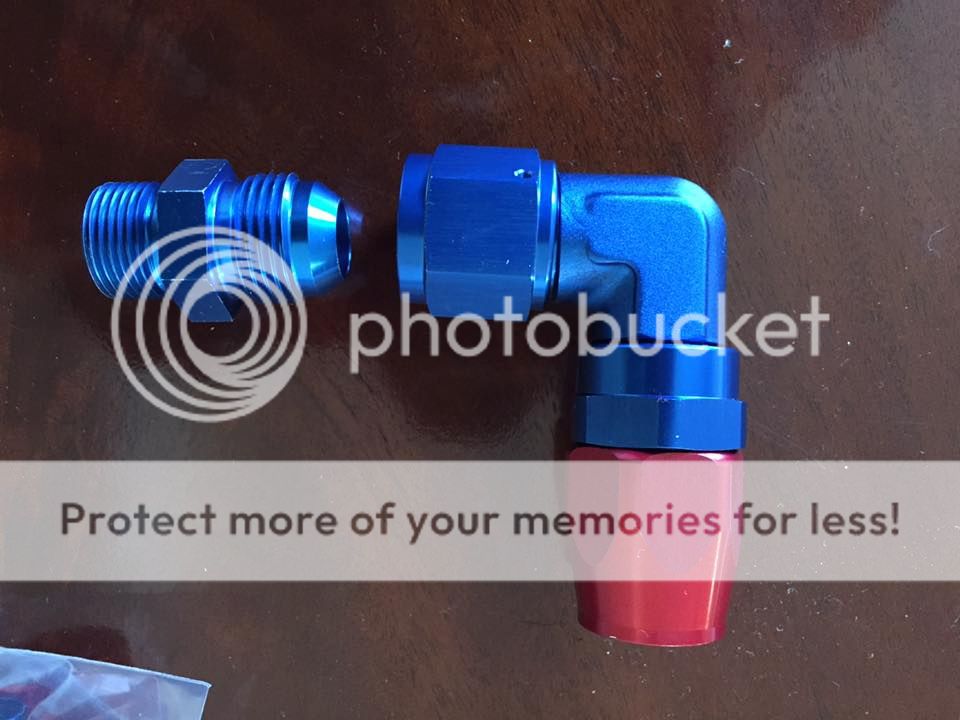

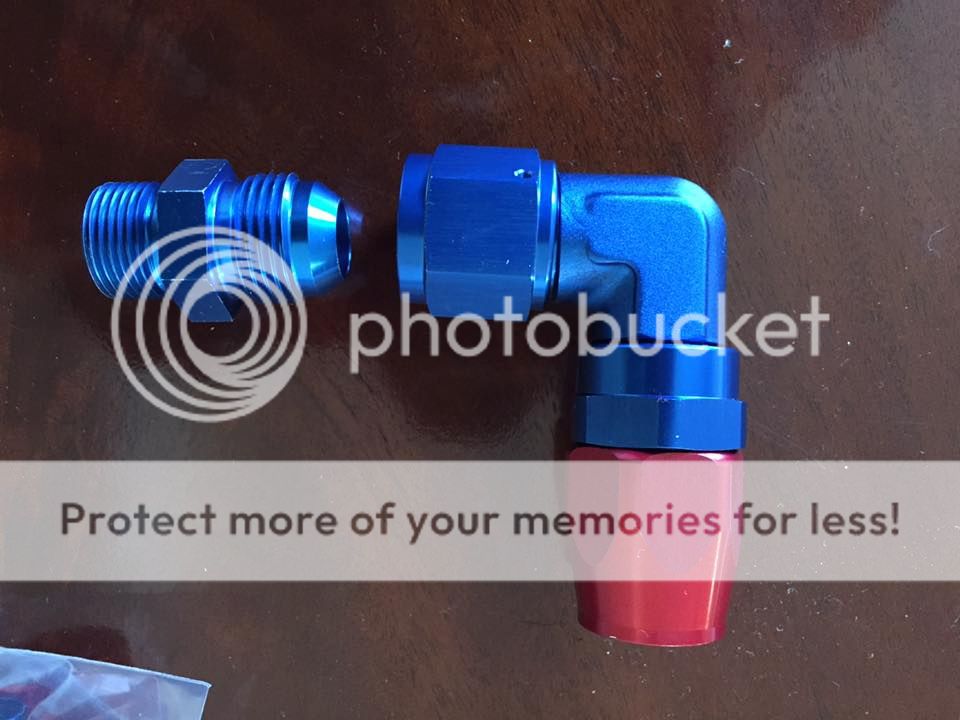

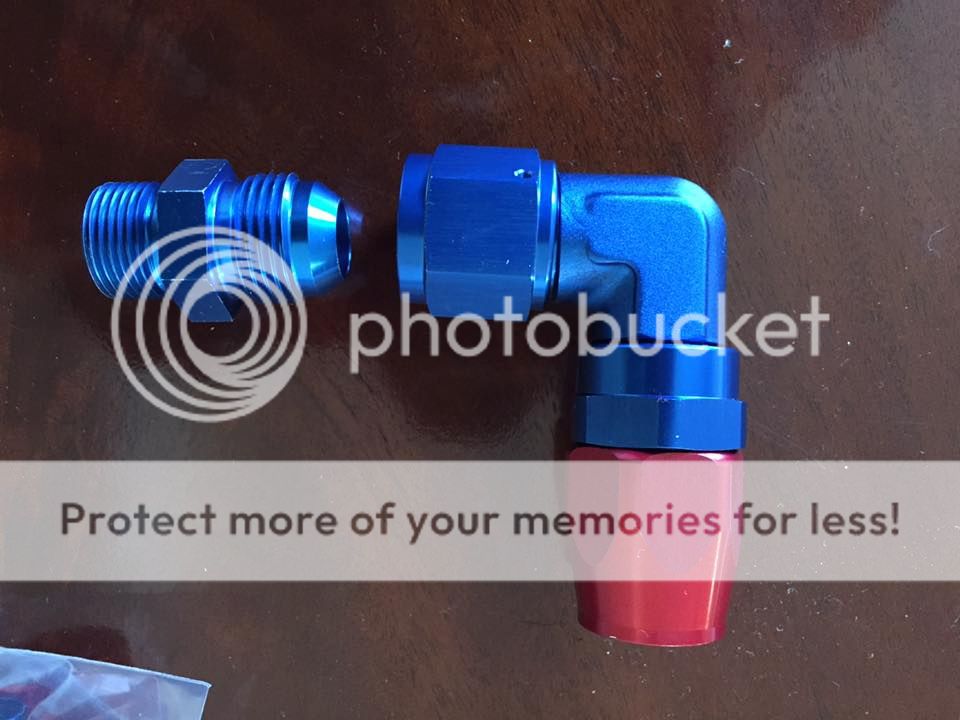

Just annoyed you can't buy what you need, anyone out there can you get a m20 1.5 pitch male to an10 male elbow, this is what I got but hits chassis...

ot but hits chassis

ot but hits chassis

ot but hits chassis

ot but hits chassisCurrent project

1972 mgb v8 4.6 roadster

1972 mgb v8 4.6 roadster

-

unstable load

- Top Dog

- Posts: 1278

- Joined: Mon May 04, 2009 6:53 am

I don't know about M20 thread, but you do get them in NPT sizes.

MS20822 is the aviation part number for the elbow, the dash numbers will denote the sizes of the fitting.

http://aircraftproducts.wicksaircraft.c ... ow-fitting

MS20822 is the aviation part number for the elbow, the dash numbers will denote the sizes of the fitting.

http://aircraftproducts.wicksaircraft.c ... ow-fitting

Cheers,

John

John

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Job done.

http://www.ebay.co.uk/itm/10-AN10-JIC-1 ... 58a046181a

http://www.ebay.co.uk/itm/HYDRAULIC-HOS ... Swj0NUfAeG

And either M20 dowty seals, alloy/copper washers, whatever takes your fancy.

http://www.ebay.co.uk/itm/10-AN10-JIC-1 ... 58a046181a

http://www.ebay.co.uk/itm/HYDRAULIC-HOS ... Swj0NUfAeG

And either M20 dowty seals, alloy/copper washers, whatever takes your fancy.

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

Given the many 90deg drillings within the oil galleries in the system, I wouldnt see a banjo being a problem at all.

Welding direct is the neatest option though. But even with say -10...the actual orifice in a lot of fittings can be much smaller than you'd like.

For my oil lines I ended up having to use -12 just to ensure no fitting/pipe was smaller than the oil galleries in the engine itself.

Oil galleries were around 12.5mm, a -10 fitting would have dropped that to around 11.5mm whereas -12 was about 14.5mm

The hoses were all large enough, just the fittings themselves dropped the bore down.

Welding direct is the neatest option though. But even with say -10...the actual orifice in a lot of fittings can be much smaller than you'd like.

For my oil lines I ended up having to use -12 just to ensure no fitting/pipe was smaller than the oil galleries in the engine itself.

Oil galleries were around 12.5mm, a -10 fitting would have dropped that to around 11.5mm whereas -12 was about 14.5mm

The hoses were all large enough, just the fittings themselves dropped the bore down.

The hoses were all large enough, just the fittings themselves dropped the bore down.[/quote]

There are quite a lot of fittings that look the same but don't do the same job, fast flow/forged made of one piece all to help the process of flow, plumbing by trade I realise flow restrictions on certain fittings, a banjo compared to a forged elbow I believe a banjo would cause quite a bit of cavitation and restriction compared to a forged elbow, anything that can help the flow of oil has to be a help

There are quite a lot of fittings that look the same but don't do the same job, fast flow/forged made of one piece all to help the process of flow, plumbing by trade I realise flow restrictions on certain fittings, a banjo compared to a forged elbow I believe a banjo would cause quite a bit of cavitation and restriction compared to a forged elbow, anything that can help the flow of oil has to be a help

Current project

1972 mgb v8 4.6 roadster

1972 mgb v8 4.6 roadster

-

stevieturbo

- Forum Contributor

- Posts: 3979

- Joined: Sat Nov 18, 2006 6:22 pm

- Location: Northern Ireland

There are quite a lot of fittings that look the same but don't do the same job, fast flow/forged made of one piece all to help the process of flow, plumbing by trade I realise flow restrictions on certain fittings, a banjo compared to a forged elbow I believe a banjo would cause quite a bit of cavitation and restriction compared to a forged elbow, anything that can help the flow of oil has to be a help[/quote]BISH V8 wrote:The hoses were all large enough, just the fittings themselves dropped the bore down.

The smallest bit is usually the bit that extends into the flexible portion of hose. No way around that really other than using larger fittings.

The banjo may pose more of a restriction that a typical swept fitting etc...but again, as all the internal oilways are full of sharp 90deg turns. I wouldnt be concerned about it. The banjo probably flows a lot better than those.

Although I always try and get a burr inside the oil galleries to try and smooth any turns as best as possible. Some just cant be reached though. Probably not needed...but they always bug me lol