Throttle Cable

Posted: Thu Sep 14, 2017 8:15 am

I am in the process of changing my RV8 from the Zenith carbs to a Thor injection manifold. Basically all sorted and just doing the last odd and ends. The vehicle is a Landrover FC 101.

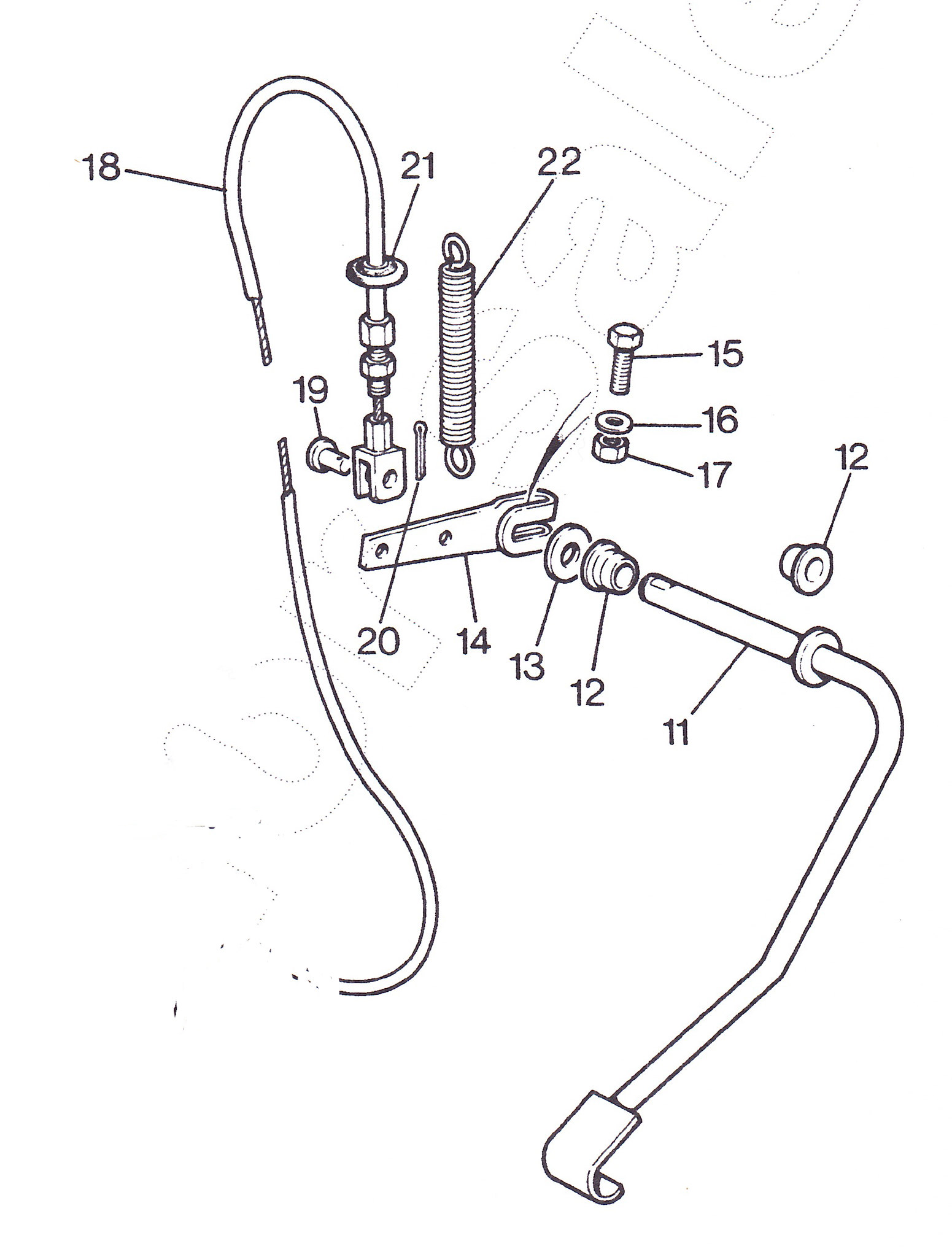

Finally got around trying to a fitting the accelerator cable that I knew would be too short if I used the standard mounts so was prepared to make an extension which works fine. I didn't want to get a new throttle cable made as the 101 has a propensity to to break cables at the pedal end so staying standard is easier to replace.

The problem I have is that with every connected up with the cable tight with no slack there is not enough pedal travel to fully open the throttle butterfly. With the pedal up, the cable tight and the butterfly closed and then putting the pedal to the floor, the butterfly opens only to about 90% - the butterfly does start to open as soon as soon as the pedal is moved so the cable is adjusted up correctly.

So open to suggestions - the lever on the pedal cannot be realistically modified as it is hidden up behind the brake boosted and is almost impossible to get at. Was thinking of drilling a pivot in the front of the inlet plenum and putting a lever on it activated by the standard cable and having a hole higher up the lever with the extension I made connected so movement of the pedal is magnified at the throttle body. Another option is to build a new smaller throttle body external quadrant but that is a pretty big job.

So after suggestions.

Thanks

Garry

Finally got around trying to a fitting the accelerator cable that I knew would be too short if I used the standard mounts so was prepared to make an extension which works fine. I didn't want to get a new throttle cable made as the 101 has a propensity to to break cables at the pedal end so staying standard is easier to replace.

The problem I have is that with every connected up with the cable tight with no slack there is not enough pedal travel to fully open the throttle butterfly. With the pedal up, the cable tight and the butterfly closed and then putting the pedal to the floor, the butterfly opens only to about 90% - the butterfly does start to open as soon as soon as the pedal is moved so the cable is adjusted up correctly.

So open to suggestions - the lever on the pedal cannot be realistically modified as it is hidden up behind the brake boosted and is almost impossible to get at. Was thinking of drilling a pivot in the front of the inlet plenum and putting a lever on it activated by the standard cable and having a hole higher up the lever with the extension I made connected so movement of the pedal is magnified at the throttle body. Another option is to build a new smaller throttle body external quadrant but that is a pretty big job.

So after suggestions.

Thanks

Garry