Page 6 of 6

Posted: Thu Jul 27, 2017 7:09 pm

by B33fy

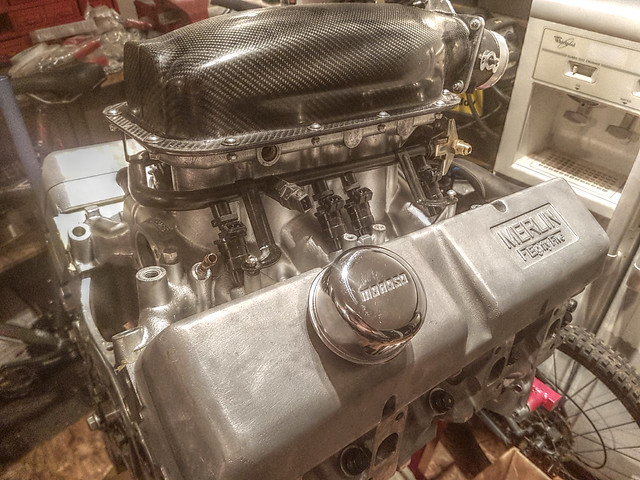

stevieturbo wrote:Intake looks great !

Can't beat a bit of Carbon Steve, though its pretty good underneath too..

Posted: Wed Oct 11, 2017 6:33 pm

by B33fy

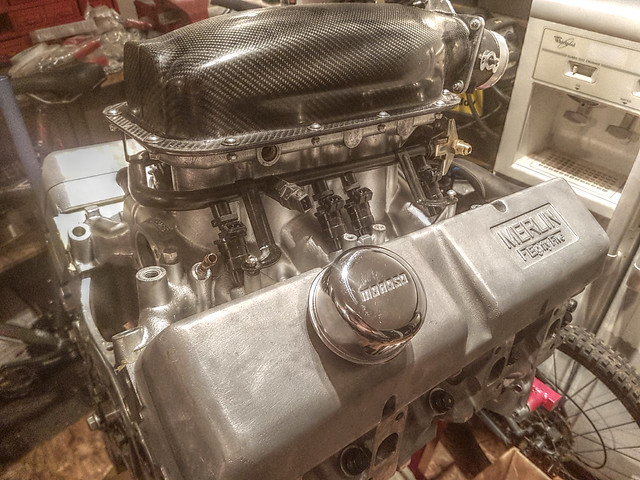

Engine slowly coming together, stripped bottom end and found a knackered bearing so crank is away being looked at, awaiting an outcome. Going for 4.0 pistons, compression works out about 10.5:1

Threw the heads on to check valve to piston clearance, got over 6mm with the 4.6 pistons. Should have enough with the 4.0 pistons will check again once installed.

Posted: Thu Dec 28, 2017 12:17 am

by B33fy

Started the final build. Using ARP mains bolts with cross bolts. The cross bolts seem very short, most only needing three turns to tighten, that’s without the dowty washers. Anyone tell me the length of the normal cross bolts? I guess some of the threads in the caps start deeper than others. Will take a closer look tomorrow.

Posted: Thu Dec 28, 2017 5:07 pm

by ChrisJC

That seems a bit odd to me. I don't have a cross-bolt to hand, but they seemed 'normal' to me when I fitted them, I would guess 1/2 an inch of bolt goes into the cap.

Chris.

Posted: Thu Dec 28, 2017 9:47 pm

by B33fy

The ARP cross bolts are all 5 mm too short compared with the standard ones. Hey ho.

The crank is way too tight also. Took out the middle thrust bearing and it’s fine so it seems there is no end float or tolerance at all. Anyone know if over size bearings are oversize for the thrust face as well?

I did check to see if the thrust bearing had splayed out when fitting as it was pretty tight, but seems flat enough.

Posted: Thu Dec 28, 2017 11:36 pm

by stevieturbo

Does it say anything on the bearing or box ?

I'm sure you can get oversize thrusts...but as to whether it is standard practise for them to be oversize along with the main journal...no idea.

You'd think you would need to specify this.

How do they actually measure ? And before turning etc, you must have all the bolts incl side bolts torqued up

Posted: Fri Dec 29, 2017 8:28 pm

by ChrisJC

The crank will be tight until the cross-bolts are correctly torqued as well.

Chris.

Posted: Fri Dec 29, 2017 10:30 pm

by B33fy

There is no end float clearance to allow the crank to drop into the bearings, requiring a small amount of persuassion. To turn the crank I have to use a 3ft breaker bar.

I removed the thrust bearing and reassembled and it’s fine, rotating nicely. The end float clearance needs looking it. There’s no clearance or float when dropping the bearing straight onto the crank. This is probably exaggerated with a little spread when the bearing is fitted into the block.

I’ll measure it up properly at the weekend and get onto Connaught engineering when they reopen next week.

Posted: Fri Dec 29, 2017 11:13 pm

by stevieturbo

Certainly sounds wrong....if the bearings are oversized, I'm sure it is bound to say on them or the packaging somewhere.

Posted: Sat Dec 30, 2017 11:05 am

by B33fy

stevieturbo wrote:Certainly sounds wrong....if the bearings are oversized, I'm sure it is bound to say on them or the packaging somewhere.

The crank was reground, the mains +10, the bearings (king) were supplied by the engineering company to supposedly match the grind.

Re: 4.6 Build.. Spec ideas?

Posted: Mon Jan 22, 2018 10:49 pm

by B33fy

The company (Connaught) that ground the crank are now saying they gave me the wrong bearings, they should be +20 which doesn’t make sense as they would be more oversize and less likely to fit. Popped the Turners and spoke to the engine builder. He said sometimes king bearing come up slightly oversize especially when spread slightly when fitted on the block. They can be adjusted by a couple of thou using some fine wet and dry/ emery on a flat surface.

Cut a long story short also grabbed some standard size bearings. The +10’s measure up about 12 thou wider taking up the end float and a bit more. Bloke at Connaught is not well currently, so no chance of sorting the crank in a hurry, so bought a brand new old stock crank and fitted it. 5 thou of end float and all is good. Build back on track, for now anyhow.

Re: 4.6 Build.. Spec ideas?

Posted: Mon Jan 29, 2018 5:57 pm

by B33fy

Picked up the crank today, all seems to measure up. All journals have been ground +20. Now got the right bearings to suit. Despite both old and new thrusts measuring the same width, new one fits and the old one doesn’t. Very odd.

Anyhow now surplus to requirements if anyone is interested in a fresh ground crank and new king bearings, first £250 secures. Collection only from Kent.

Re: 4.6 Build.. Spec ideas?

Posted: Mon Jan 29, 2018 6:04 pm

by Coops

Roscco any good for a future build?

Re: 4.6 Build.. Spec ideas?

Posted: Mon Jan 29, 2018 6:47 pm

by Rossco

Yes....but Kent is in the far end of beyond

Re: 4.6 Build.. Spec ideas?q1

Posted: Sun Mar 04, 2018 2:36 pm

by B33fy

Ongoing bearing problems with Connaught.. Supplied me a set of rod bearing for an SD1, went back up there Friday and sorted it out. Also sorted the proper thrust bearing. Had the crank measured by someone else, the thrust faces are standard width. The thrust supplied was 10 thou over and when it spreads, the crank don’t fit. There is an option for a standard width thrust in +20 This has been told to Connaught very clearly and the proper bearing are expected in the post very soon. I have sold the crank with the bearings but wanted it right before it went as I couldn’t put someone else through the hassle I’ve had.